Waste gas processing system and using method thereof

A waste gas treatment and waste gas technology, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation, can solve the problems of increasing the cost of activated carbon, inability to effectively remove dioxin, and poor efficiency of dioxin, so as to improve efficiency and increase Likelihood, an effect that increases the chance of a collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

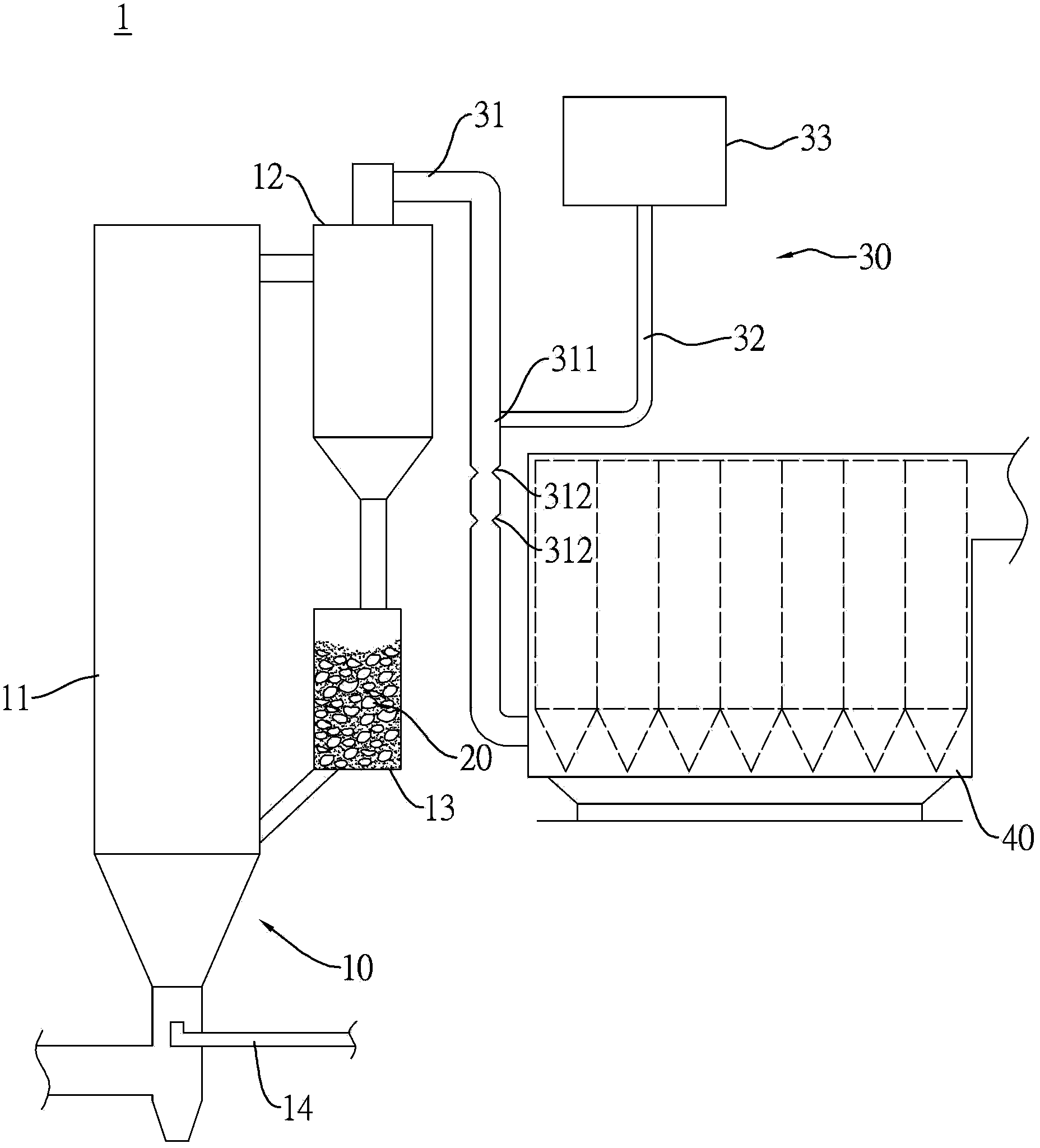

[0070] see figure 1 As shown, the exhaust gas treatment system 1 of this embodiment includes a circulating fluidized bed semi-dry acid removal device 10 (circulating fluidized bed semi-dry scrubber equipment), an inert substance 20, an activated carbon adsorption device (active carbon absorber equipment , ACAE) 30, and a bag dust collector 40.

[0071] The aforementioned circulating fluidized bed semi-dry acid removal device 10 includes a reactor 11, a collection equipment dust 12 connected with the reactor 11, a circulation storage tank 13 connected with the reactor 11 and the dust collection equipment 12 And an alkali agent injection device 14 connected with the reactor 11, the reactor 11 can be used to import a waste gas, and the alkali agent injection device 14 can be used to import an alkali agent. In the present embodiment, the dust collection equipment 12 is It is a cyclone dust collector.

[0072] The aforementioned inert substance 20 is contained in the circulation ...

Embodiment 2

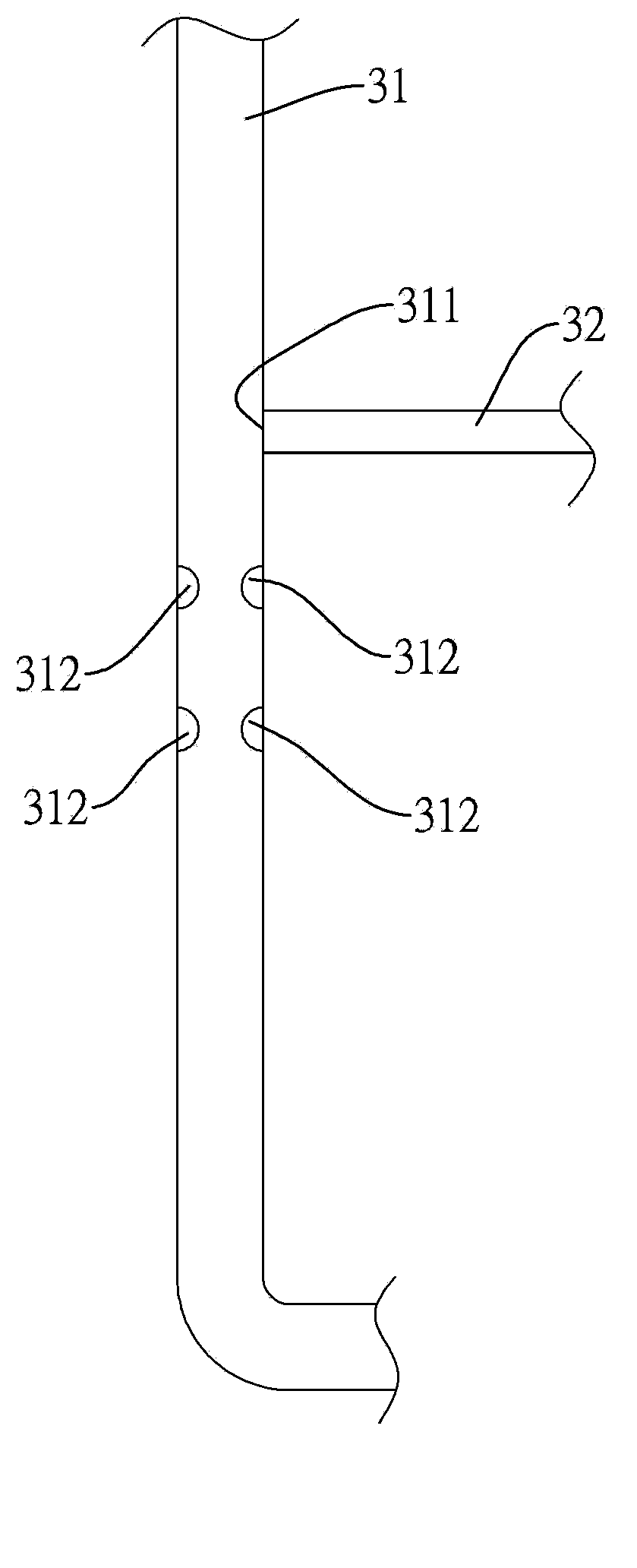

[0076] see figure 2 As shown, the difference between the exhaust gas treatment system of this embodiment and that of Embodiment 1 is that the inner wall of the delivery pipe 31 is provided with a plurality of spoiler structures 312, and these spoiler structures 312 are bumps, and this part has bumps The passage cross-sectional area of the conveying pipe 31 is smaller than the passage cross-sectional area of the conveying pipe 31 of the other parts.

Embodiment 3

[0078] The waste gas treatment system of this embodiment is different from that of Embodiment 1 in that the dust collection device 12 is a louver type inertial dust collector.

[0079] Application of the waste gas treatment system of the present invention

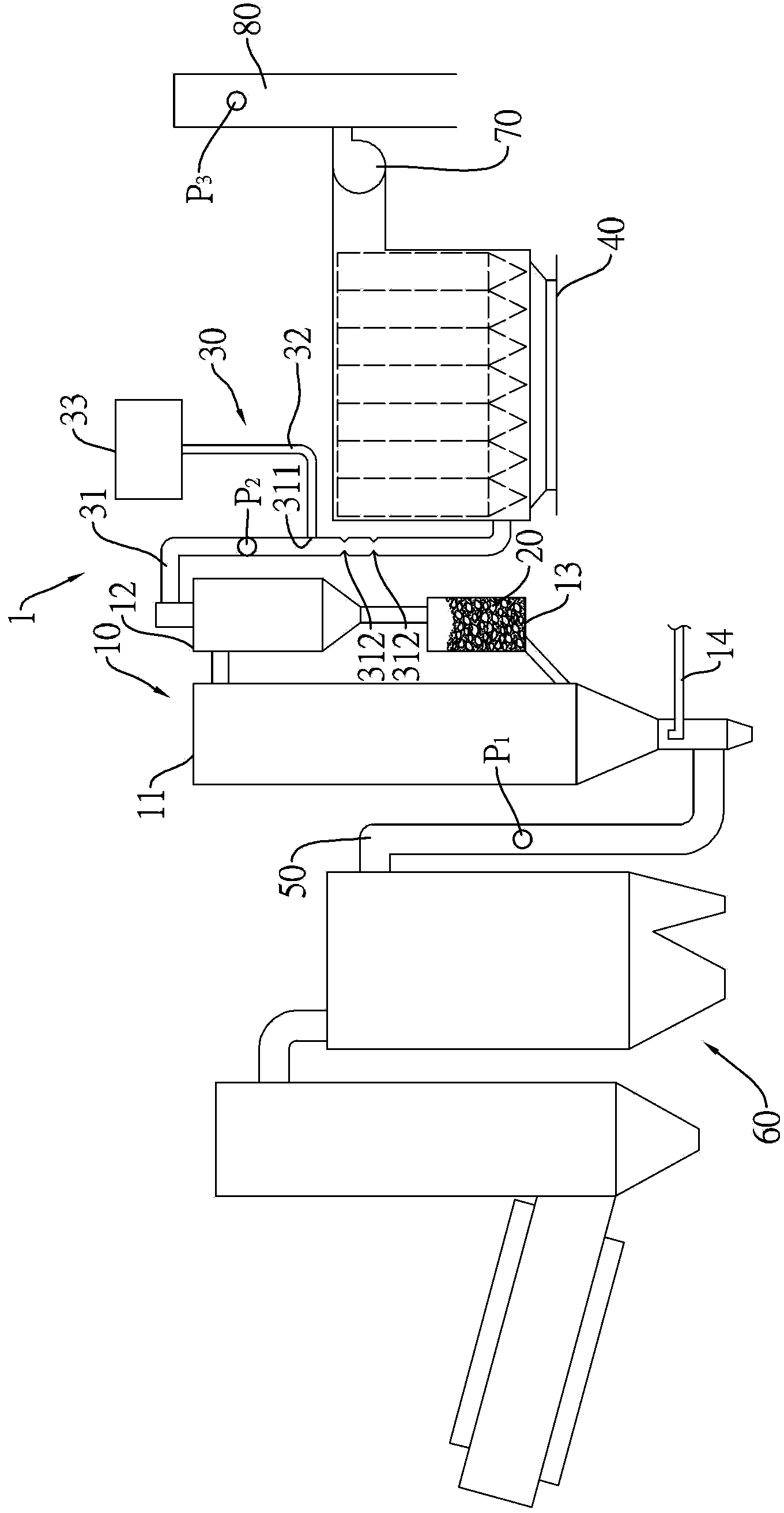

[0080] see image 3 As shown, when the exhaust gas treatment system 1 of Embodiment 1 of the present invention is used in an incinerator, the circulating fluidized bed semi-dry acid removal device 10 is connected with a boiler 60 by a conduction pipe 50, and an induced fan 70 It is connected with the bag dust collector 40 , and a chimney 80 is connected with the induced fan 70 .

[0081] Method of using exhaust gas treatment system of the present invention

[0082] Example 1

[0083] see Figure 4 As shown, the aforementioned incinerator equipped with the waste gas treatment system 1 of the present invention is equipped, and the quartz sand in the circulating storage tank 13 is injected with a wind speed of 6 to 10 mete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com