Formation method of junction structure having peeling property

A technology of peelability and structure, applied in the field of formation of joint structure, can solve the problems of change of peelability and poor peelability, and achieve the effect of high pressure resistance, stable heat sealing strength and excellent peelability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

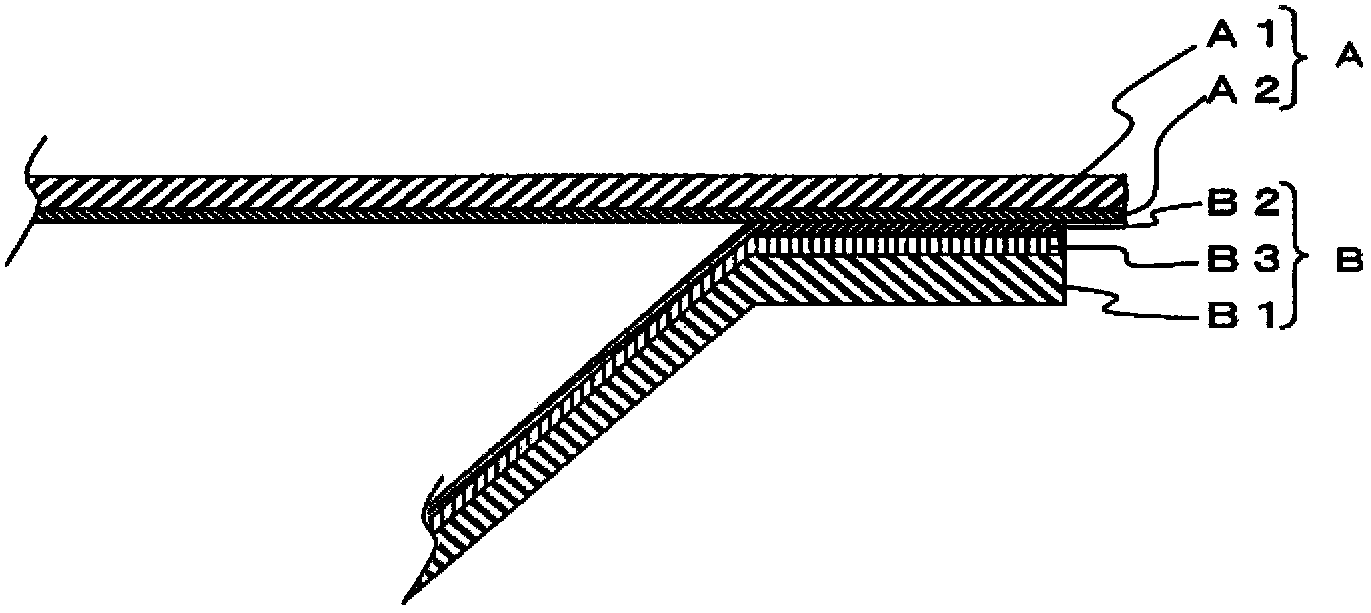

Image

Examples

Embodiment 1

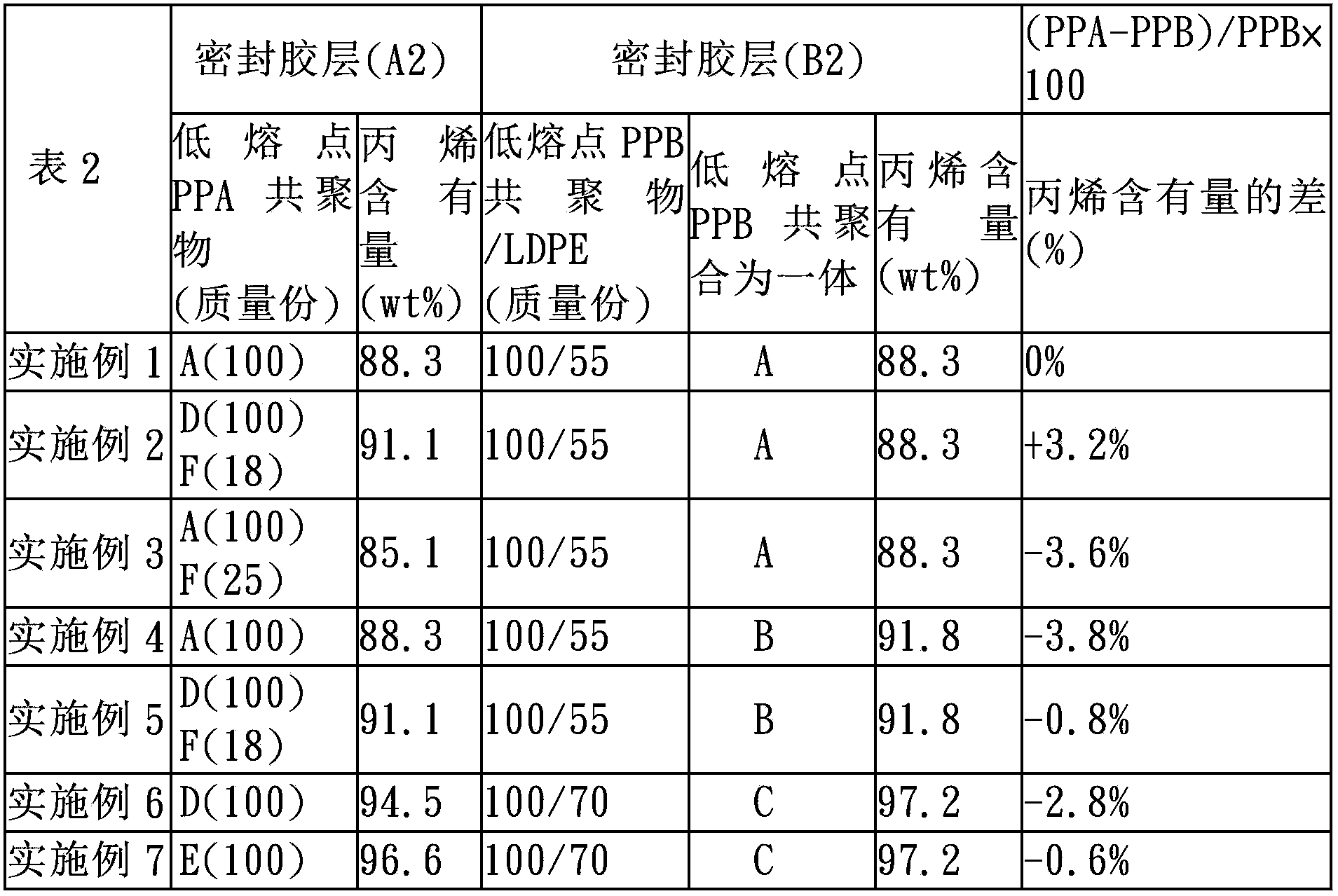

[0130]

[0131] 1) Resin for the main layer (A1)

[0132] For 100 parts by mass of propylene single polymer (MFR=2.0g / 10min, melting point=162°C), mix 1.5 parts by mass of antifogging agent (0.5 parts by mass of stearyl monoglyceride and stearyl diethanolamine monostearic acid A mixture of ester and stearyl diethanolamine (1.0 parts by mass) was used as the resin for the main layer (A1).

[0133] 2) Resin for sealant layer (A2)

[0134] Resin A shown in table 1 (propylene·ethylene·butylene random copolymer (ethylene content=2.7wt%, butene content=9.0wt%, propylene content=88.3wt%, MFR=5.0g / 10 minutes, melting point =134°C)) 100 parts by mass, mixed with 0.2 parts by mass of an anti-blocking agent (amorphous silica, average particle diameter = 2.0 μm), and 0.1 parts by mass of a lubricant (erucamide) as a sealant layer (A2) Use resin.

[0135] 3) Film making

[0136] In the state of three layers of laminated sealant layer resin / main layer resin / sealant layer resin, co-ext...

Embodiment 2~7、 comparative example 1~9

[0146] The raw material resin of the sealant layer (A2) of the biaxially stretched sheet (A) containing the sealant layer and the raw material resin of the sealant layer (B2) of the thermoplastic resin member (B) were changed to those shown in Table 2 or Table 3. Other than that, the joint structure was formed in the same procedure as in Example 1. The evaluation results are shown in Table 4. In Example 2, a mixture of 100 parts by mass of resin D and 18 parts by mass of resin F was used as the sealant resin of the sealant layer (A2), and the propylene content of the mixed resin was shown. The same applies to other examples.

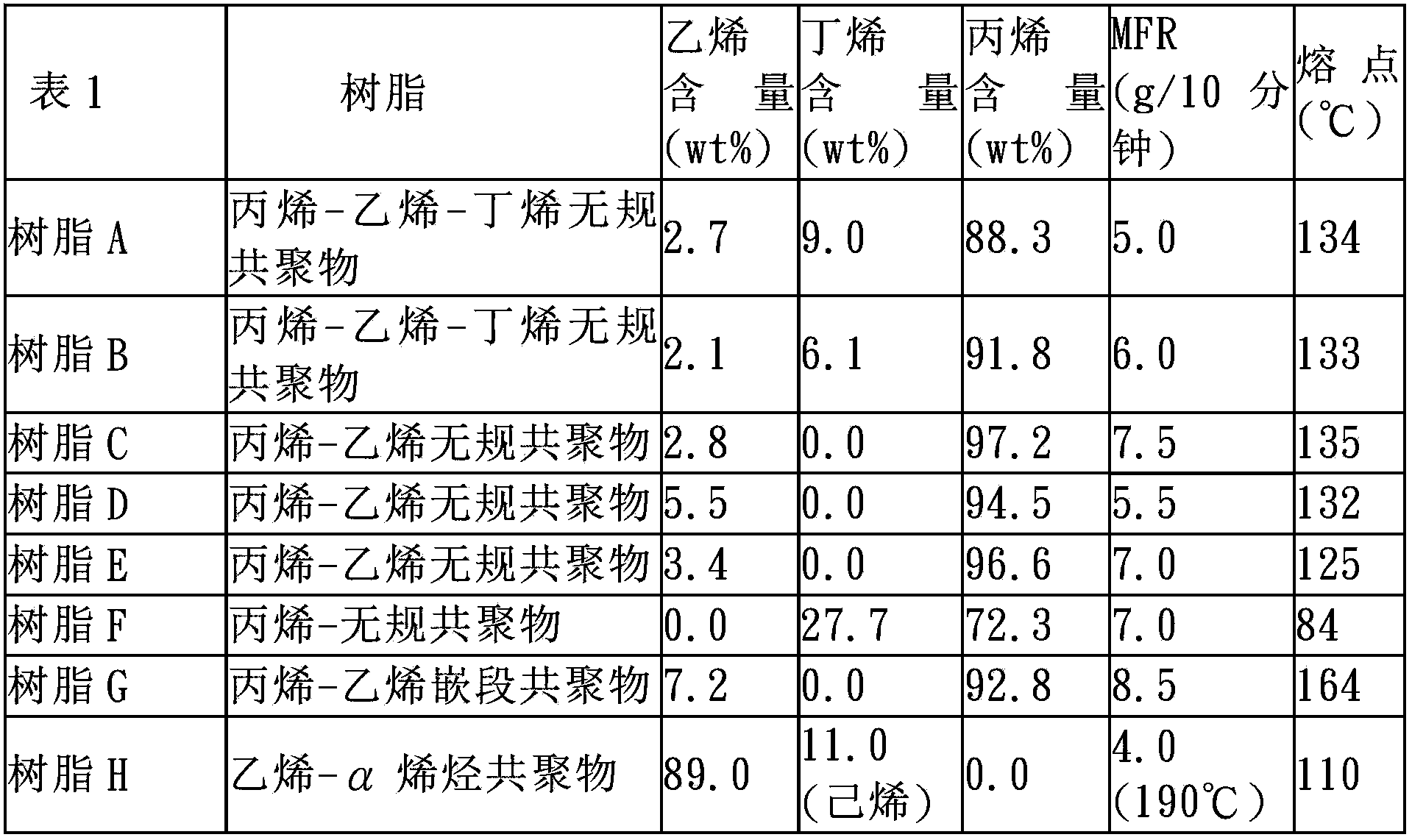

[0147] Table 2

[0148]

[0149] table 3

[0150]

[0151] Table 4

[0152]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com