Gas burner

A gas burner and a burner technology, which are applied in the directions of burners, gas fuel burners, combustion methods, etc., can solve the problem that it is difficult to meet the natural stratification law of bottled liquefied petroleum gas, uneven aeration without a head channel, and difficult to meet the Gas source instability and other problems, to achieve the effect of reducing mutual interference, stabilizing firepower, and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Now in conjunction with accompanying drawing, the present invention will be further described:

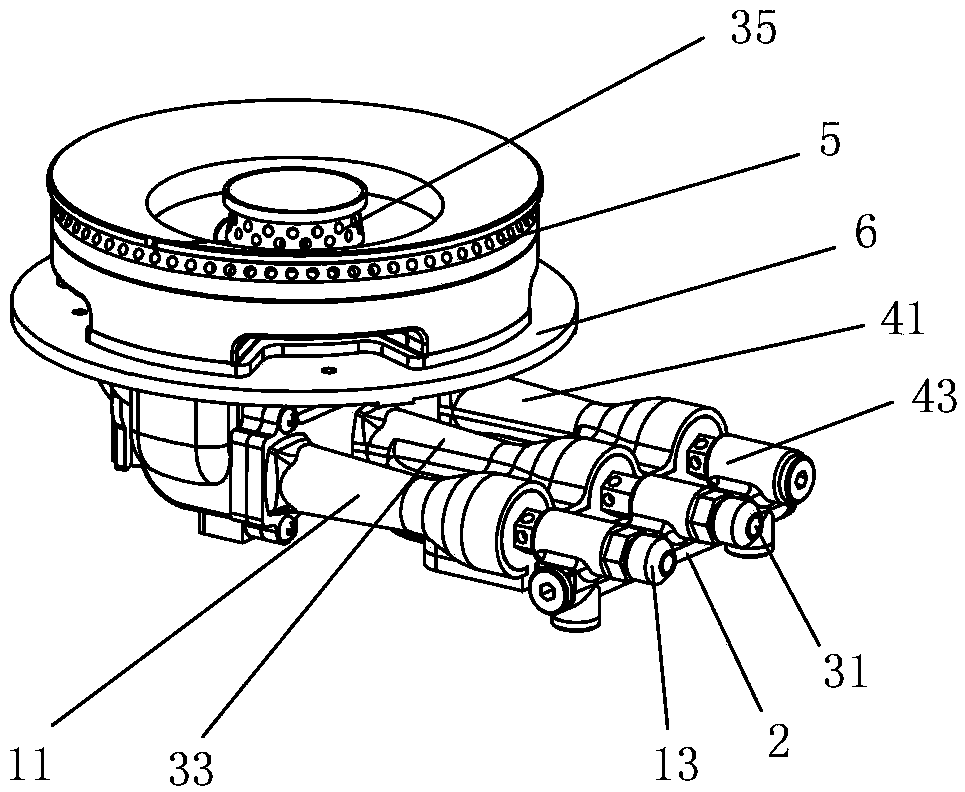

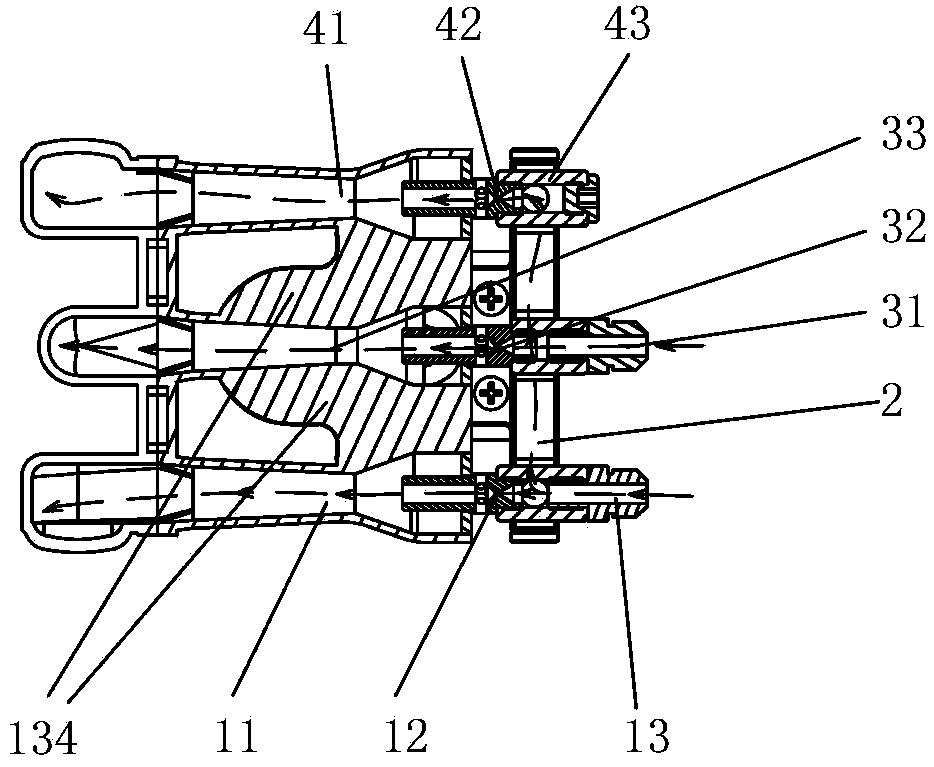

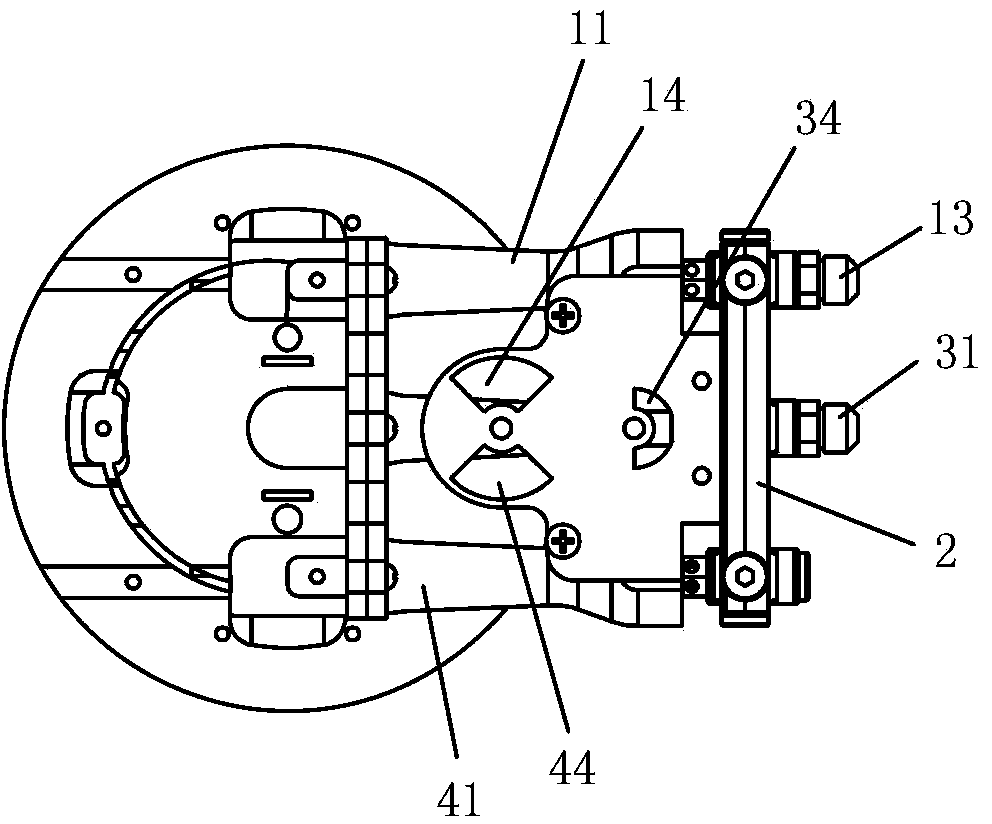

[0031] A gas burner, comprising an injection tube assembly, a burner base 6, an outer ring burner 5 and an inner ring burner 35;

[0032] Injection tube assembly includes:

[0033] The gas pipe sub-joint 31, sub-nozzle 32, and sub-injection pipe 33 communicated with the gas pipe are connected in sequence, and the sub-injection pipe 33 is also communicated with the auxiliary primary air inlet 34;

[0034] The first air pipe main joint 13, the first main nozzle 12, and the first main ejector pipe 11 communicated with the gas pipe, and communicated in sequence, and the first main ejector pipe 11 is also communicated with the first main primary air inlet 14;

[0035] The second air pipe main joint 43, the second main nozzle 42 and the second main injection pipe 41 are communicated in sequence, and the second main ejection pipe 41 is also communicated with the second main primar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com