Beam shaping device for semiconductor laser

A beam shaping and laser technology, applied in optics, instruments, optical components, etc., can solve the problems of large power value and poor beam quality, etc., and achieve the effect of improving comprehensive beam quality and good beam quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

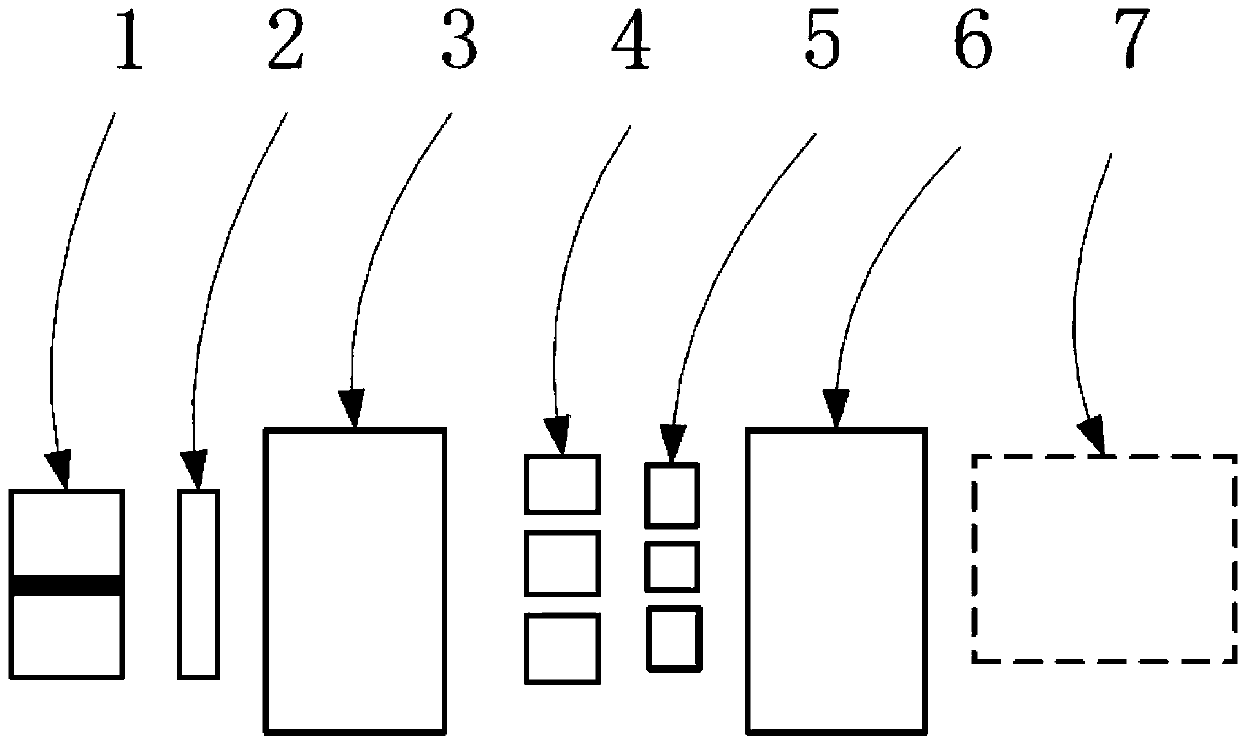

[0023] The device of the present invention is as figure 1 shown.

[0024] Below in conjunction with accompanying drawing, preferred specific embodiment of the present invention is described:

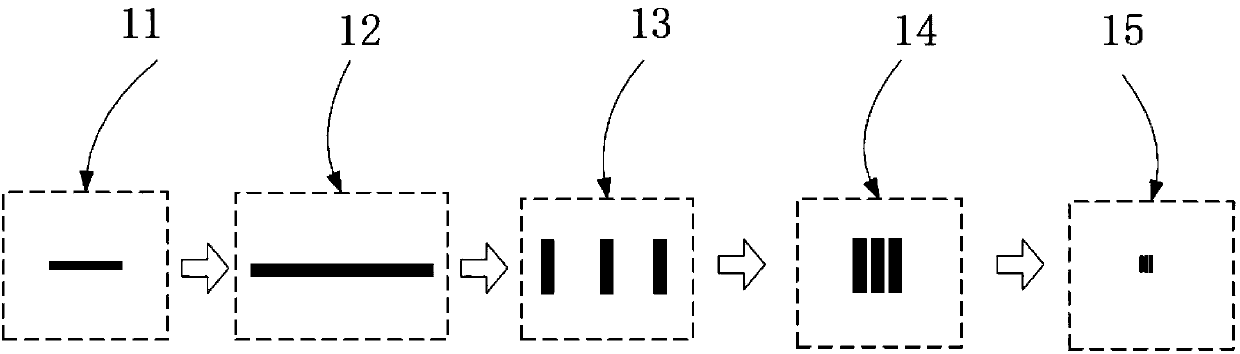

[0025] A semiconductor laser die 1 with 975nm, output power of 10W, output bar width Lx=150 microns, and optical mode field thickness Ly=1 micron is used. The divergence angle of the fast axis (y axis) is 70°, and the slow axis (x axis) The divergence angle is 18°, and it is mounted on an aluminum nitride transition heat sink and a copper heat sink. The original BPP of the semiconductor laser die 1 is 0.34 mm.mrad on the y-axis and 9.8 mm.mrad on the x-slow axis. Use the first fast-axis collimating lens 2 to partially collimate the fast axis of the semiconductor laser tube core 1, so that the image of the light-emitting surface of the tube core basically overlaps in the fast-axis direction and the slow-axis direction to form a unified image. The y divergence angle is 30°, the x diverg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com