BCD integrated device and manufacturing method of BCD integrated device

A technology of integrated devices and oxide semiconductors, which can be used in semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., and can solve the problems of limited application scope, high cost of buried layer and epitaxial layer process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

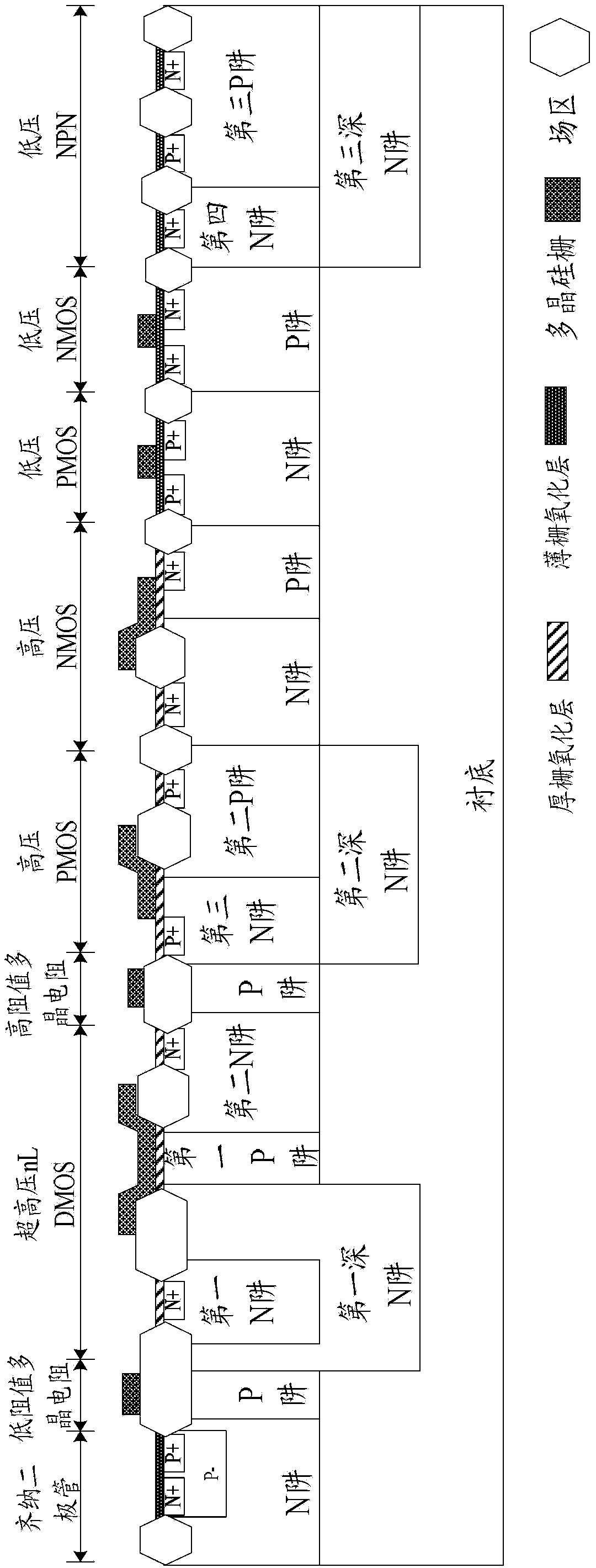

[0028] The BCD integrated device introduced in the embodiment of the present invention adopts a non-epitaxial process to form an ultra-high voltage nLDMOS, a high voltage PMOS and a low voltage NPN in a P-type single crystal substrate. Since the ultra-high voltage nLDMOS, high voltage PMOS and low voltage NPN are directly fabricated in the substrate, no epitaxial layer in the traditional process is required, thereby reducing the manufacturing cost, improving the cost performance, expanding its application range, and making up for the shortcomings of the existing technology .

[0029] The embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

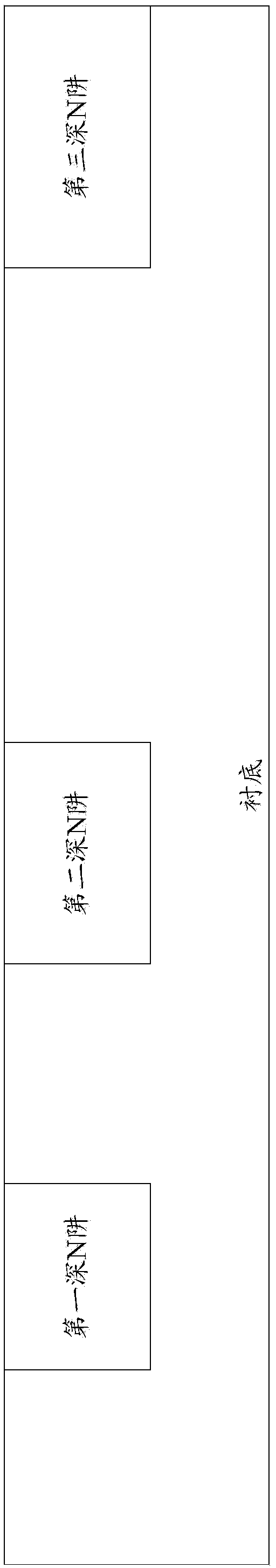

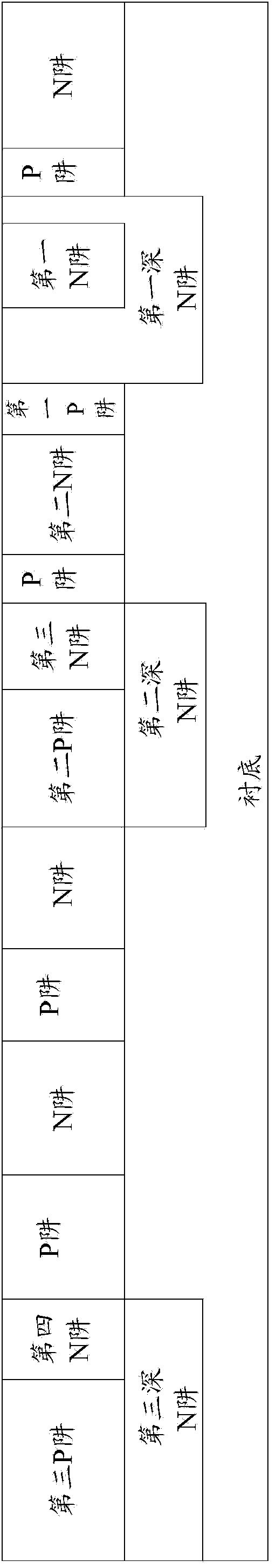

[0030] In practice, in order to reduce manufacturing costs, non-epitaxial processes can be used to fabricate devices in the substrate; in the embodiment of the present invention, ultra-high voltage nLDMOS, high-voltage PMOS and low-voltage NPN are located in the subst...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap