Method for charging battery pack

A charging method and technology of battery packs, which are applied in secondary battery charging/discharging, secondary battery repair/maintenance, etc., and can solve problems such as thermal runaway, uneven current intensity, and fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] For a battery pack connected in parallel, it is composed of ten 18650 lithium titanate batteries. The positive electrode of the lithium titanate battery is lithium cobalt oxide material, and the negative electrode is lithium titanate material. The rated capacity is 1Ah, the rated internal resistance is 5mΩ, and the rated The voltage is 2.4V.

[0040] For the 1C charging of the parallel battery pack, the traditional method (that is, directly charging with 1C) and according to The method increases the charging current of each battery cell to 1C (1 ampere) and then performs constant current charging. The two methods were carried out for 1000 charge and discharge cycles, and the comparison results are shown in Table 1:

[0041] Wherein: the maximum bias current rate between battery cells refers to (same as in other embodiments):

[0042] In the 1000 times of charging process, one charging process is randomly selected in every 100 times, for example: in the 1-100 charging...

Embodiment 2

[0050] For a battery pack connected in parallel, it is composed of ten 26650 lithium titanate batteries. The positive electrode of the lithium titanate battery is lithium cobalt oxide material, the negative electrode is lithium titanate material, the rated capacity is 2.5Ah, and the rated internal resistance is 6mΩ. Nominal voltage is 2.4V.

[0051] For the 2C charging of the parallel battery pack, adopt the traditional method (that is, charge directly at 2C) and according to The way to increase the charging current to 2C (5 amps) and then carry out constant current charging. The two methods were carried out for 1000 charge and discharge cycles, and the comparison results are shown in Table 2:

[0052] In this embodiment, B=0.1, S=20, R=2, A=6, V=2

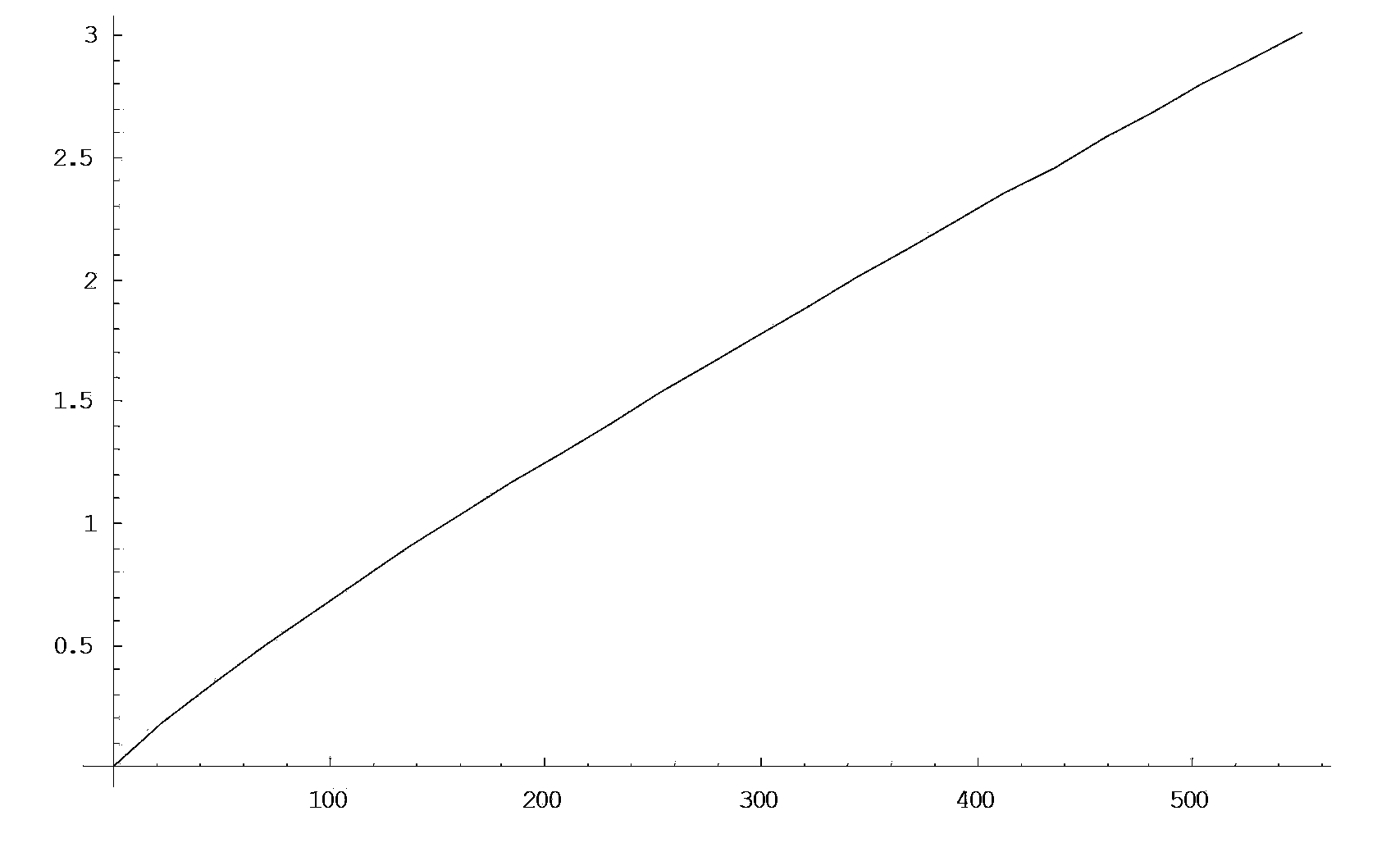

[0053] attached figure 2The current intensity-time curve in the variable current charging stage of this embodiment is given, and it can be seen that the variable current charging stage lasts about 50 seconds.

[0054] Table ...

Embodiment 3

[0057] For a parallel battery pack, it consists of 20 18650-type lithium iron phosphate batteries. The positive electrode of the iron phosphate battery is lithium iron phosphate material, and the negative electrode is graphite material. The rated capacity is 1Ah, the rated internal resistance is 3mΩ, and the rated voltage is 3.4 V.

[0058] For the 3C charging of the parallel battery pack, adopt the traditional method (that is, directly charge with 3C) and according to The way to increase the charging current to 3C (3 amps) and then carry out constant current charging. The two methods were carried out for 1000 charge and discharge cycles, and the comparison results are shown in Table 3:

[0059] In this embodiment, B=0.5, S=5, R=2, A=3, V=2

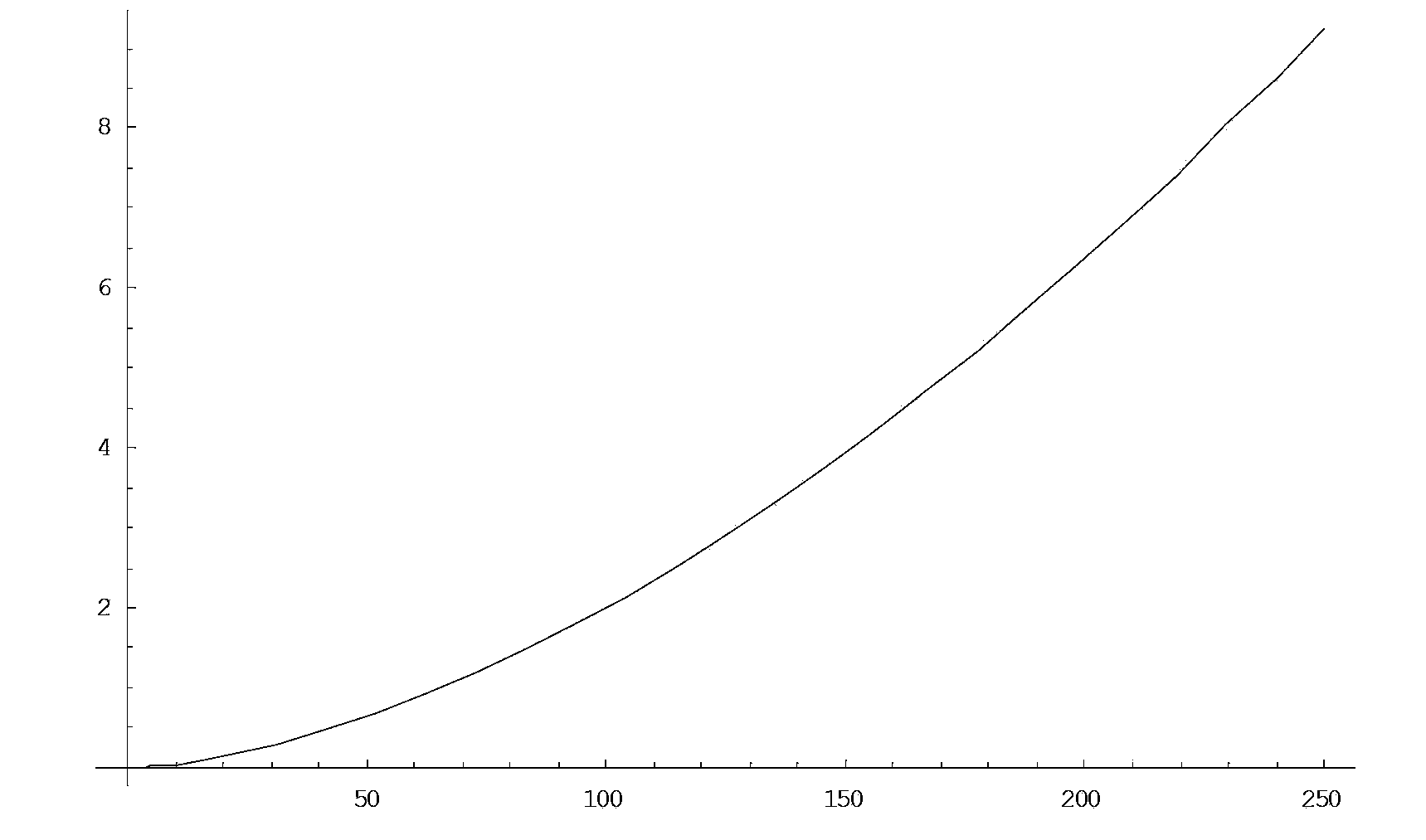

[0060] attached image 3 The current intensity-time curve in the variable current charging stage of this embodiment is given, and it can be seen that the variable current charging stage lasts about 550 seconds.

[0061] table 3

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com