Drivers for Vertical Cavity Surface Emitting Lasers

A surface emission, vertical cavity technology, used in lasers, laser parts, semiconductor lasers, etc., can solve the problem of insufficient suppression of light wave waveform attenuation, and achieve the effects of compensating attenuation, optimizing light wave signals, and suppressing nonlinearity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

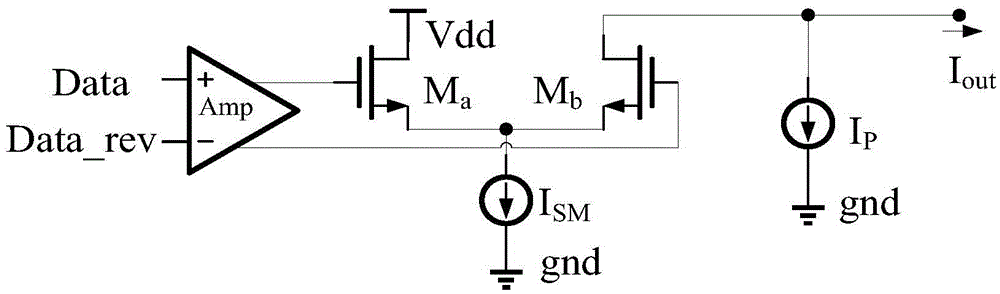

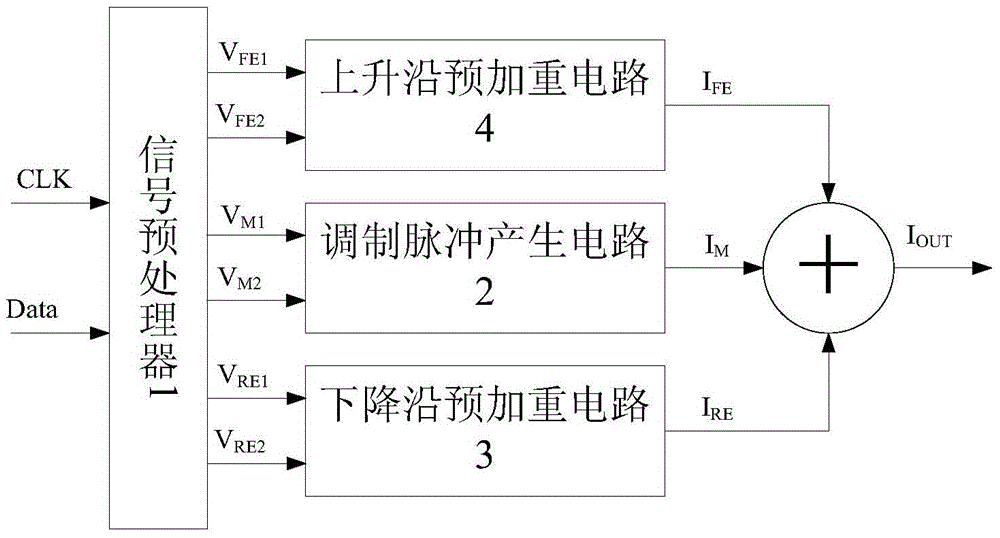

[0044] refer to image 3 , the VCSEL driver of the present invention includes a signal preprocessor 1 , a modulation pulse generation circuit 2 , a rising edge pre-emphasis circuit 3 and a falling edge pre-emphasis circuit 4 . The pulse generation circuit 2, the falling edge pre-emphasis circuit 3 and the rising edge pre-emphasis circuit 4 are respectively connected to the three groups of output terminals of the signal preprocessor 1; the modulation pulse generation circuit 2 inputs the differential synchronous data voltage signal V M1 and V M2 Converted to the initial modulation current I with a bias current component M ; The falling edge pre-emphasis circuit 3, on the differential falling edge voltage signal V FE1 and V FE2 When they are high level and low level respectively, the input differential falling edge voltage signal V FE1 and V FE2 Converted to falling edge pre-emphasis current I FE ; The rising edge pre-emphasis circuit 4, at the differential rising edge vo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com