Chemical carbon dioxide gas generator

A gas generator, carbon dioxide technology, applied in the field of applied chemistry, can solve problems such as unusable fire extinguishers, unsuitable gas, unfavorable oxygen reactivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

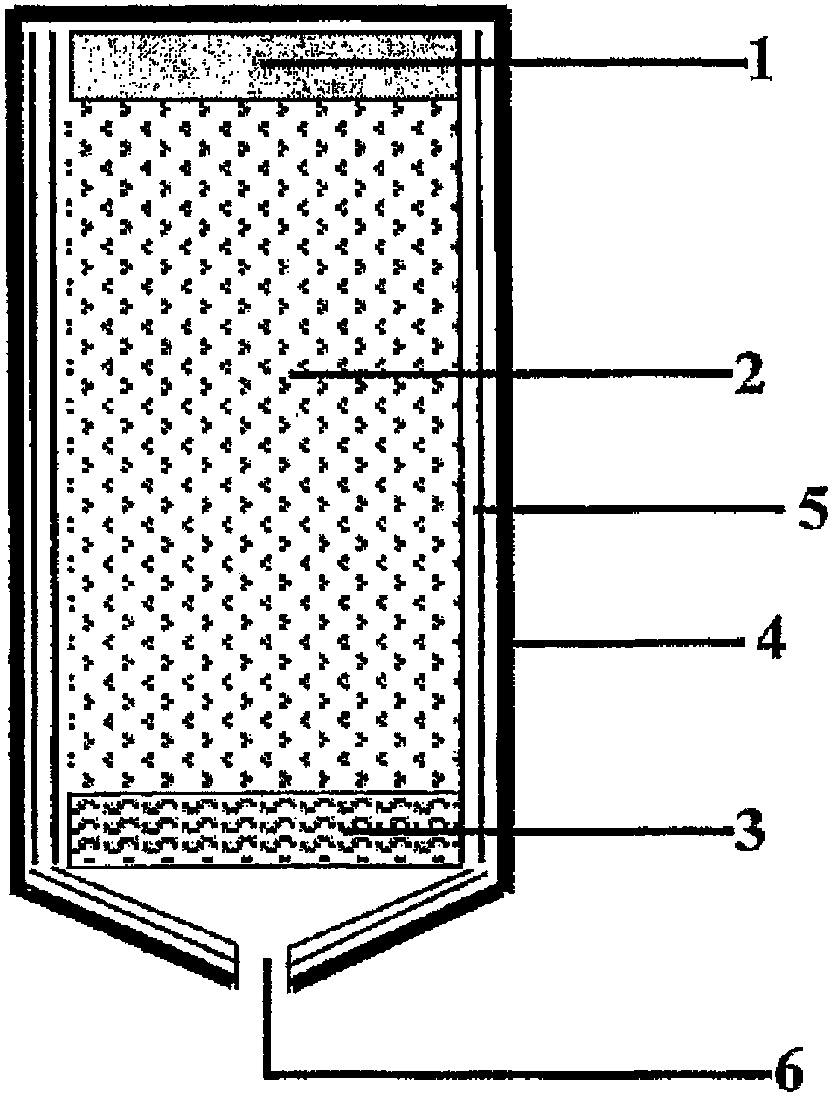

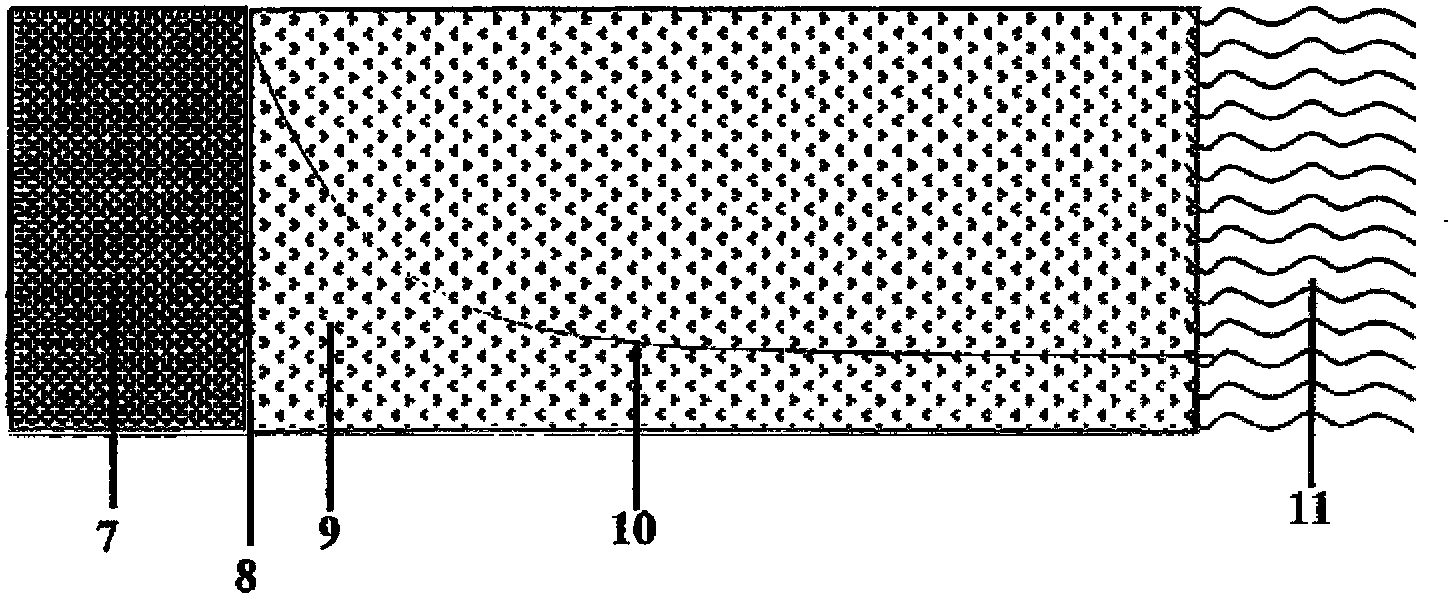

Method used

Image

Examples

preparation example Construction

[0055] The preparation of charges with suitable properties may be based on methods known per se, for example based on the methods described in WO03 / 009899 or WO01 / 23327, combined with the information disclosed herein, common general knowledge and optionally some routine testing.

[0056] As mentioned above, the charge is permeable to the gas produced. Advantageously, therefore, the charge is of such a structure that channels (openings) are contained in the structure. Such a structure may in particular be provided by granular material in which the particles are bound together (by means of a binder). The gas can pass through the interstices between the particles, and / or - if the particles are porous - through the pores in the particles. Usually, the porosity (ε p ) in the range of 0.2-0.75. For good gas flow performance, good material strength and good CO 2 Productivity, preferably, the porosity is in the range of 0.30-0.65. In particular, the porosity (ε p Good results ha...

Embodiment

[0097] A charge consisting of magnesium carbonate, oxidizer, fuel and binder was prepared as follows: the dry powder was weighed and mixed thoroughly. Add the water soluble binder with the required amount of moisture and mix well again to get a homogeneous mixture. The mixture is then granulated, sieved, and placed into molds where it is compacted in several steps to the desired total porosity. The mold loaded with the wet porous charge was dried in an oven at a temperature range between room temperature and 150° C. according to an optimized drying profile. The charge is then removed from the mold and inspected visually.

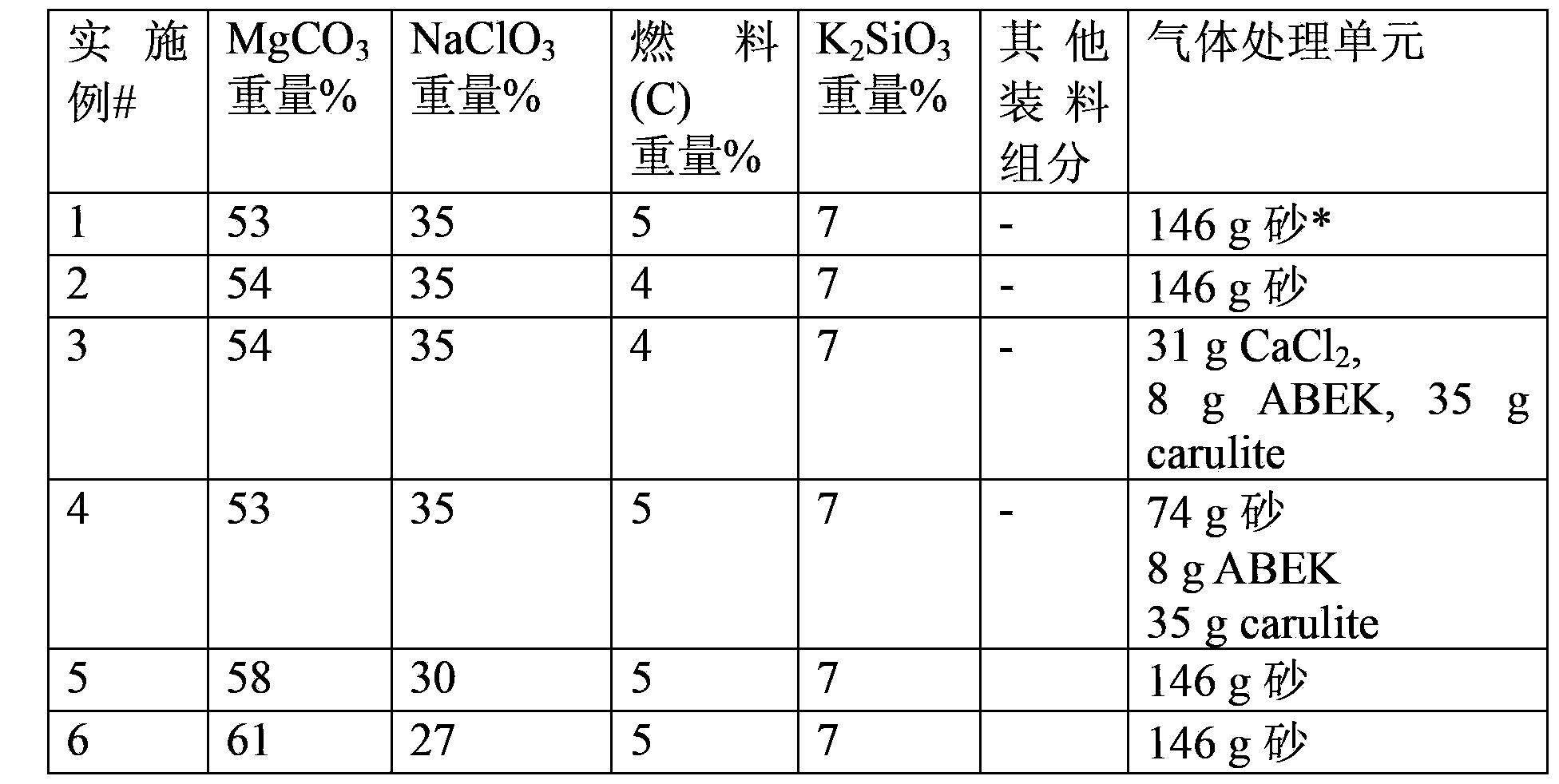

[0098] In the table below, the composition of the tested charge is given, as well as the gas treatment unit used (downstream of the charge in the gas generator). The total weight of the charge is about 100 g.

[0099]

[0100] *) Note: When using only sand, the amount used is not optimal. The amount used is that required to fill the free space in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com