Eu/BiVO4 photocatalyst as well as preparation method and application thereof

A technology of photocatalyst and reactor, which is applied in the field of photocatalytic materials, can solve problems such as multiple processes and complex processes, and achieve high photocatalytic performance, simple process flow, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

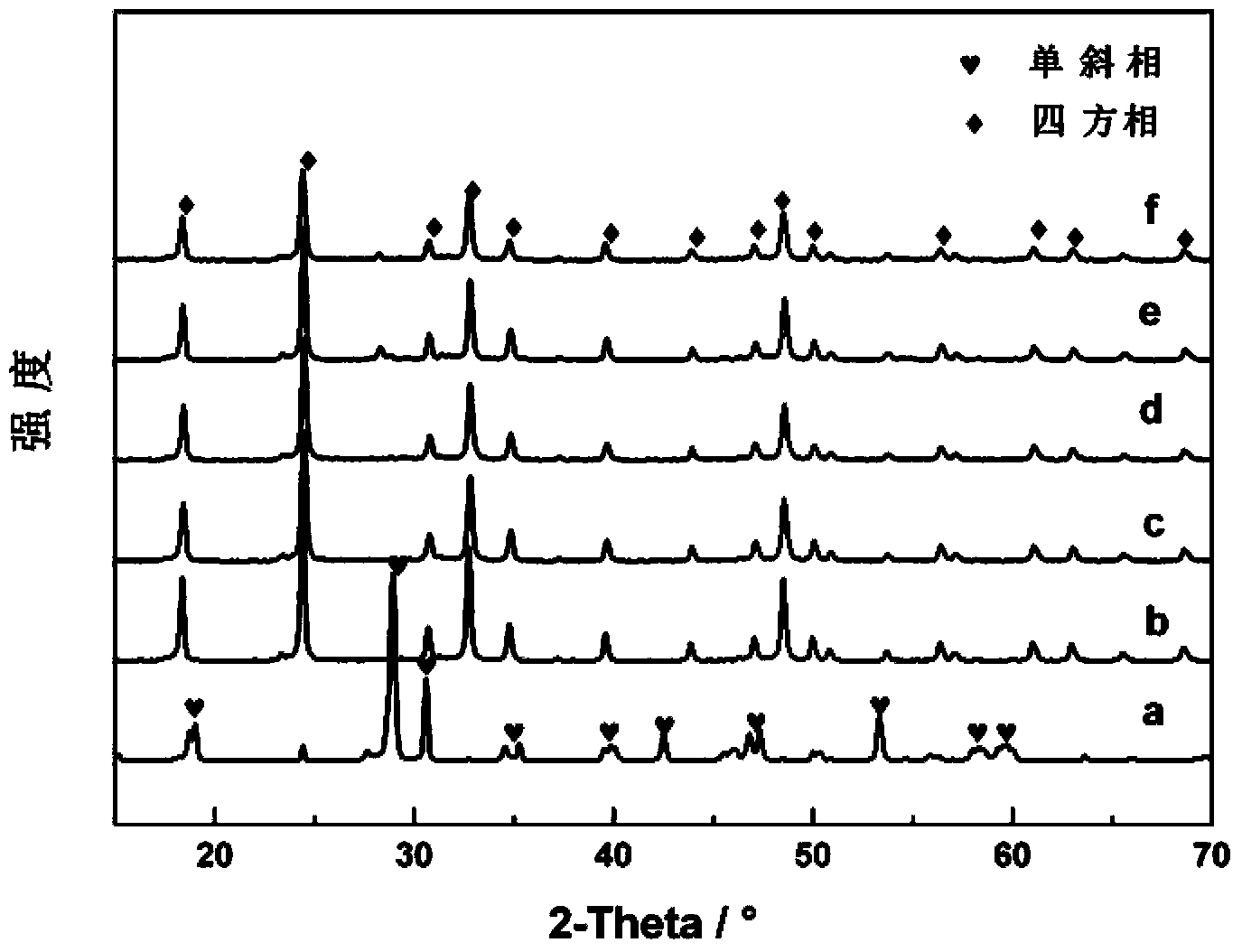

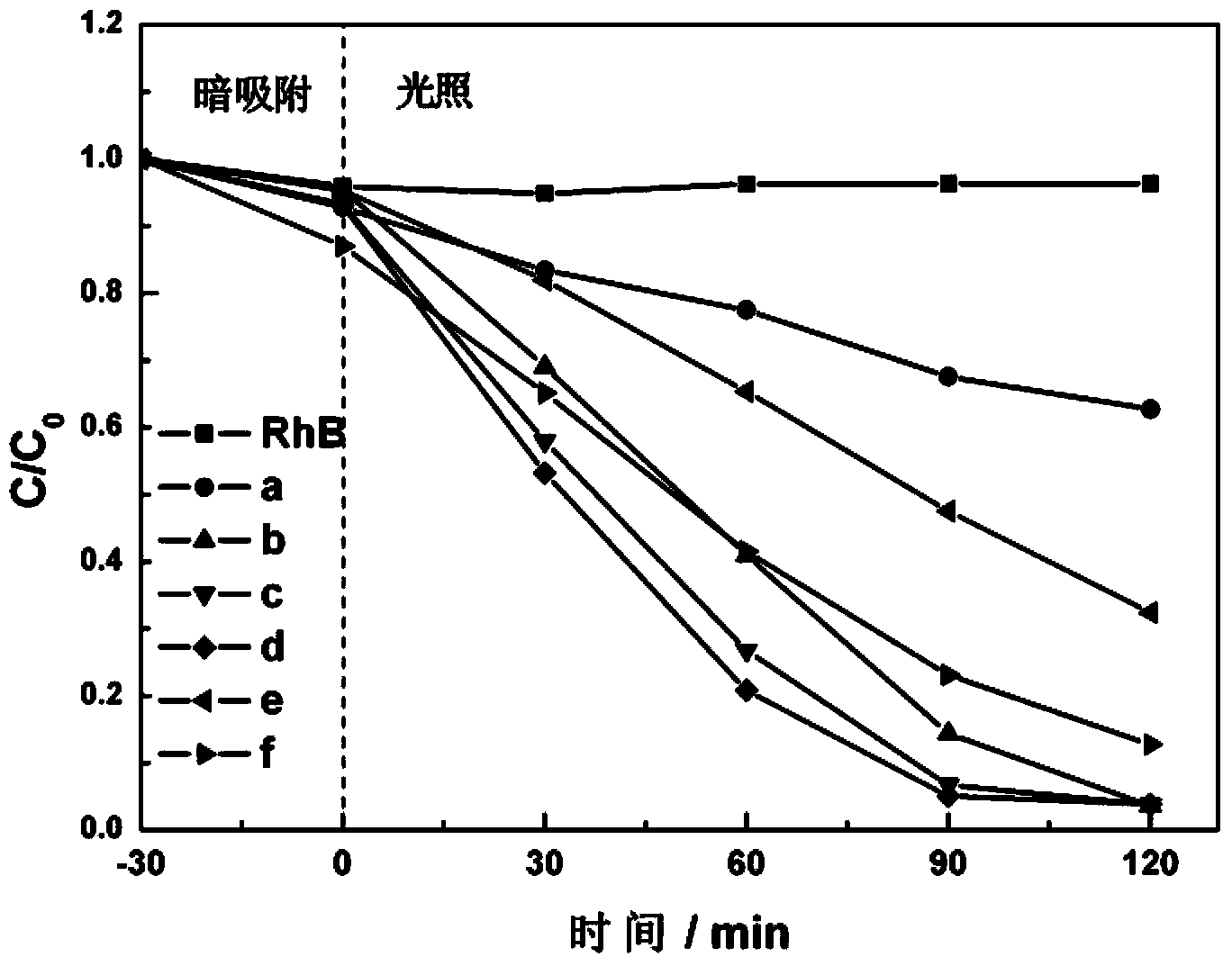

[0032] A Eu / BiVO 4 Photocatalyst whose main component is BiVO 4 , is a tetragonal zircon phase structure, and BiVO 4 The lattice contains Eu 3+ , wherein the molar ratio of Eu element to Bi element is 4.17:100.

[0033] A Eu / BiVO 4 The preparation method of photocatalyst comprises the following steps:

[0034] Step 1: Bi(NO 3 ) 3 ·5H 2 O was dissolved in deionized water and stirred on a magnetic stirrer for 20 min to obtain Bi(NO3 ) 3 ·5H 2 Bismuth salt solution with O concentration of 0.4mol / L; NH 4 VO 3 Dissolve in deionized water at 95°C, heat and stir on a magnetic stirrer at 90°C for 20min to obtain NH 4 VO 3 Concentration is the vanadium salt solution of 0.4mol / L;

[0035] Step 2: slowly drop the vanadium salt solution into the bismuth salt solution according to the molar ratio of Bi and V of 1:1, and stir on a magnetic stirrer for 15 minutes to obtain a mixed solution;

[0036] Step 3: Add dropwise NaOH solution with a concentration of 5 mol / L to the mixed...

Embodiment 2

[0041] A Eu / BiVO 4 Photocatalyst whose main component is BiVO 4 , is a tetragonal zircon phase structure, and BiVO 4 The lattice contains Eu 3+ , wherein the molar ratio of Eu element to Bi element is 6.38:100.

[0042] A Eu / BiVO 4 The preparation method of photocatalyst comprises the following steps:

[0043] Step 1: Bi(NO 3 ) 3 ·5H 2 O was dissolved in deionized water and stirred on a magnetic stirrer for 20 min to obtain Bi(NO 3 ) 3 ·5H 2 Bismuth salt solution with O concentration of 0.4mol / L; NH 4 VO 3 Dissolve in deionized water at 95°C, heat and stir on a magnetic stirrer at 100°C for 20min to obtain NH 4 VO 3 Concentration is the vanadium salt solution of 0.4mol / L;

[0044] Step 2: slowly drop the vanadium salt solution into the bismuth salt solution according to the molar ratio of Bi and V of 1:1, and stir on a magnetic stirrer for 15 minutes to obtain a mixed solution;

[0045] Step 3: Add dropwise NaOH solution with a concentration of 5 mol / L to the mi...

Embodiment 3

[0050] A Eu / BiVO 4 Photocatalyst whose main component is BiVO 4 , is a tetragonal zircon phase structure, and BiVO 4 The lattice contains Eu 3+ , wherein the molar ratio of Eu element to Bi element is 8.70:100.

[0051] A Eu / BiVO 4 The preparation method of photocatalyst comprises the following steps:

[0052] Step 1: Bi(NO 3 ) 3 ·5H 2 O was dissolved in deionized water and stirred on a magnetic stirrer for 20 min to obtain Bi(NO 3 ) 3 ·5H 2 Bismuth salt solution with O concentration of 0.4mol / L; NH 4 VO 3 Dissolve in deionized water at 95°C, heat and stir on a magnetic stirrer at 95°C for 20min to obtain NH 4 VO 3 Concentration is the vanadium salt solution of 0.4mol / L;

[0053] Step 2: slowly drop the vanadium salt solution into the bismuth salt solution according to the molar ratio of Bi and V of 1:1, and stir on a magnetic stirrer for 15 minutes to obtain a mixed solution;

[0054] Step 3: Add dropwise NaOH solution with a concentration of 5 mol / L to the mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com