A kind of mpg-c3n4/bi0.9nd0.1vo4 composite photocatalyst and its preparation method and application

A mpg-c3n4, composite light technology, applied in the direction of light water/sewage treatment, energy waste water treatment, etc., can solve the problem that the composite photocatalyst work has not been reported yet, and achieve good application prospects, mild reaction conditions, and improve efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

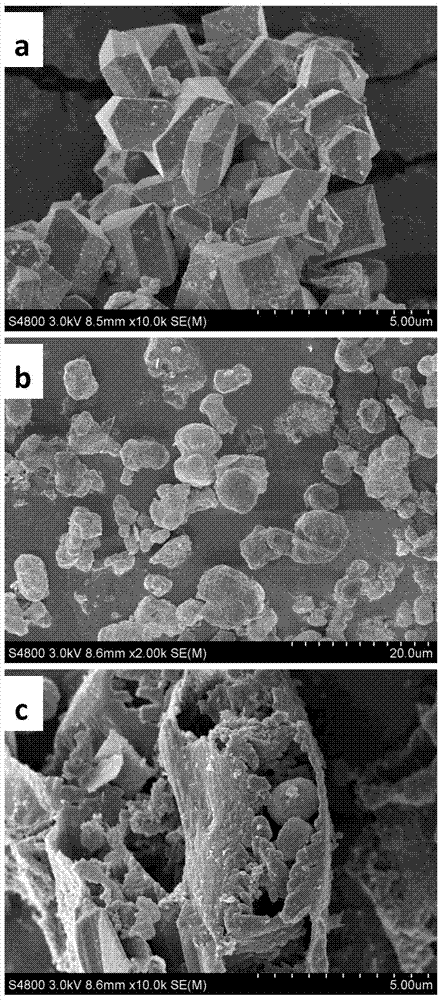

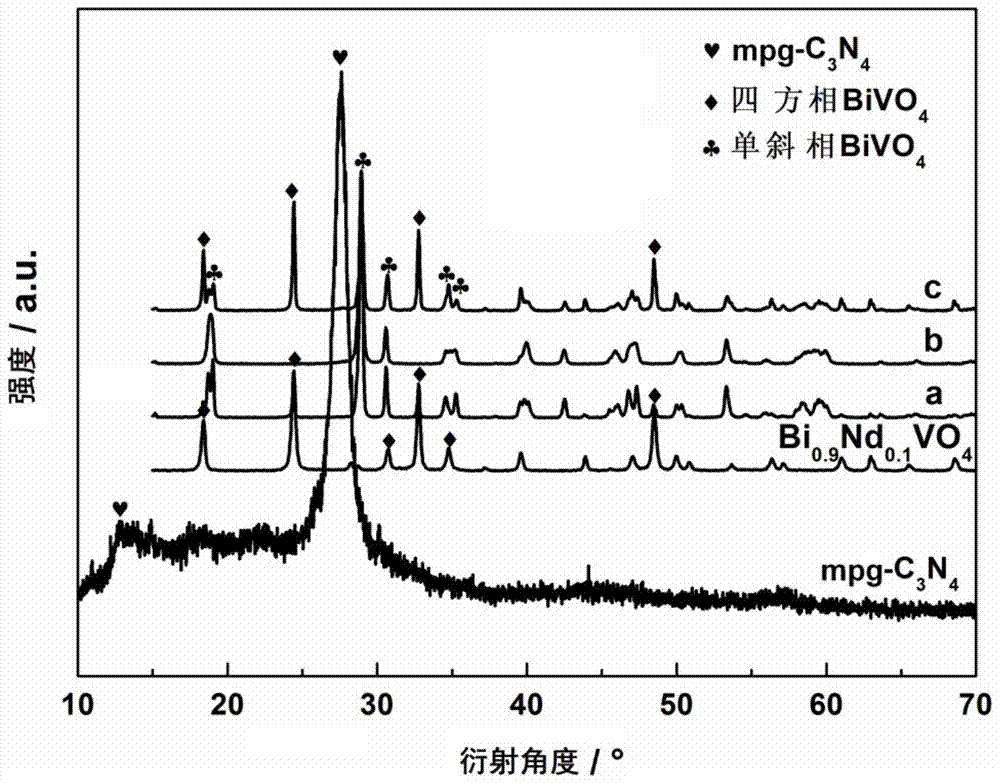

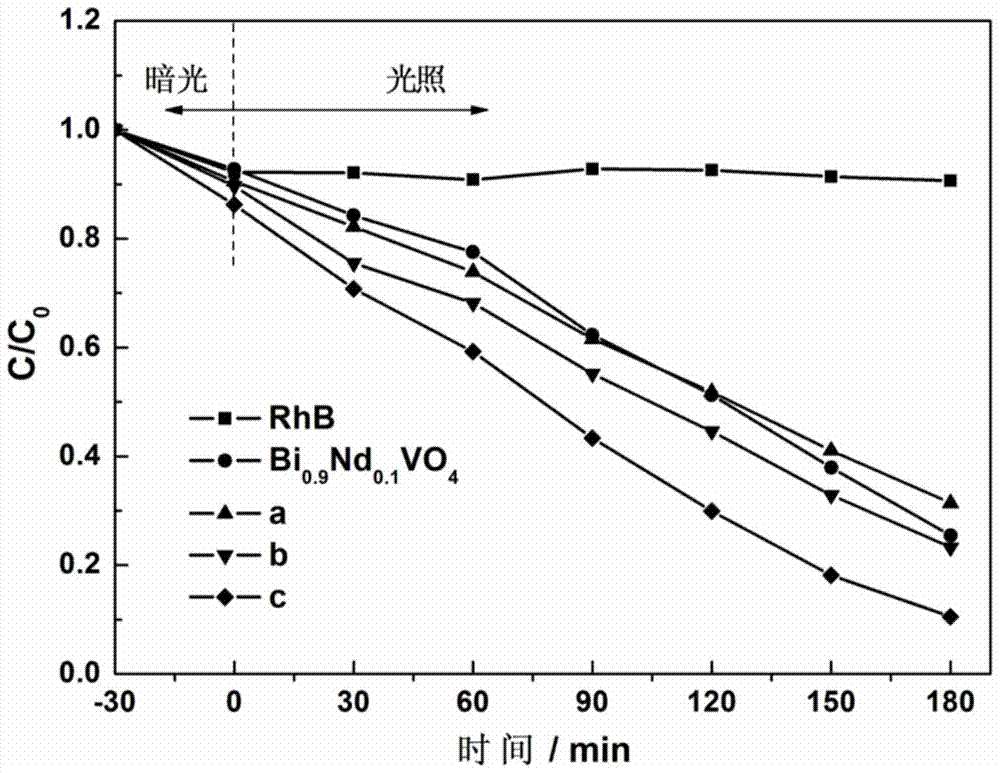

Embodiment 1

[0036] Step 1: the concentration is 2.12mol / L the melamine aqueous solution and the nanometer SiO that concentration is 0.83mol / L 2 The aqueous solution was mixed and stirred evenly according to the volume ratio of 3:2, ultrasonically dispersed for 1 hour, and then put into an oven at 80°C to dry to obtain a white solid, which was ground finely and put into a crucible. 2 In the atmosphere furnace, the heating rate was increased to 550 °C for 4 hours at a heating rate of 2.5 °C / min for calcination to obtain a light yellow powder, and then 4 mol / L NH 4 HF 2 Corrosion with aqueous solution to remove SiO in light yellow powder 2 template, and finally washed and dried to obtain mpg-C 3 N 4 Powder;

[0037] Step 2: Convert mpg-C 3 N 4 Add the powder into 5mL ethanol, and disperse ultrasonically for 2 hours to obtain mpg-C 3 N 4 Alcoholic solution; NH 4 VO 3 Dissolve in deionized water at 90°C, heat and stir at 100°C for 20min to obtain NH 4 VO 3 NH with a concentration o...

Embodiment 2

[0043] Step 1: the concentration is 2.12mol / L the melamine aqueous solution and the nanometer SiO that concentration is 0.83mol / L 2 The aqueous solution was mixed and stirred evenly according to the volume ratio of 3:2, ultrasonically dispersed for 1 hour, and then put into an oven at 80°C to dry to obtain a white solid, which was ground finely and put into a crucible. 2 In the atmosphere furnace, the heating rate was increased to 550 °C for 4 hours at a heating rate of 2.5 °C / min for calcination to obtain a light yellow powder, and then 4 mol / L NH 4 HF 2 Corrosion with aqueous solution to remove SiO in light yellow powder 2 template, and finally washed and dried to obtain mpg-C 3 N 4 Powder;

[0044] Step 2: Convert mpg-C 3 N 4 Add the powder into 5mL ethanol, and disperse ultrasonically for 2 hours to obtain mpg-C 3 N 4 Alcoholic solution; NH 4 VO 3 Dissolve in deionized water at 90°C, heat and stir at 100°C for 20min to obtain NH 4 VO 3 NH with a concentration o...

Embodiment 3

[0050] Step 1: the concentration is 2.12mol / L the melamine aqueous solution and the nanometer SiO that concentration is 0.83mol / L 2 The aqueous solution was mixed and stirred evenly according to the volume ratio of 3:2, ultrasonically dispersed for 1 hour, and then put into an oven at 80°C to dry to obtain a white solid, which was ground finely and put into a crucible.2 In the atmosphere furnace, the heating rate was increased to 550 °C for 4 hours at a heating rate of 2.5 °C / min for calcination to obtain a light yellow powder, and then 4 mol / L NH 4 HF 2 Corrosion with aqueous solution to remove SiO in light yellow powder 2 template, and finally washed and dried to obtain mpg-C 3 N 4 Powder;

[0051] Step 2: Convert mpg-C 3 N 4 Add the powder into 5mL ethanol, and disperse ultrasonically for 2 hours to obtain mpg-C 3 N 4 Alcoholic solution; NH 4 VO 3 Dissolve in deionized water at 90°C, heat and stir at 100°C for 20min to obtain NH 4 VO 3 NH with a concentration of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com