N-(4-toluenesulfonyl)-1,2-diphenyl ethylenediamine functionalized hollow PMO (Periodic Mesoporous Organosilica) catalyst preparation method

A technology of p-toluenesulfonyl and diphenylethylenediamine, which is applied in the field of preparation technology of hollow PMO catalysts, can solve the problems of limited catalytic activity, inability to uniformly disperse catalysts and reaction systems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

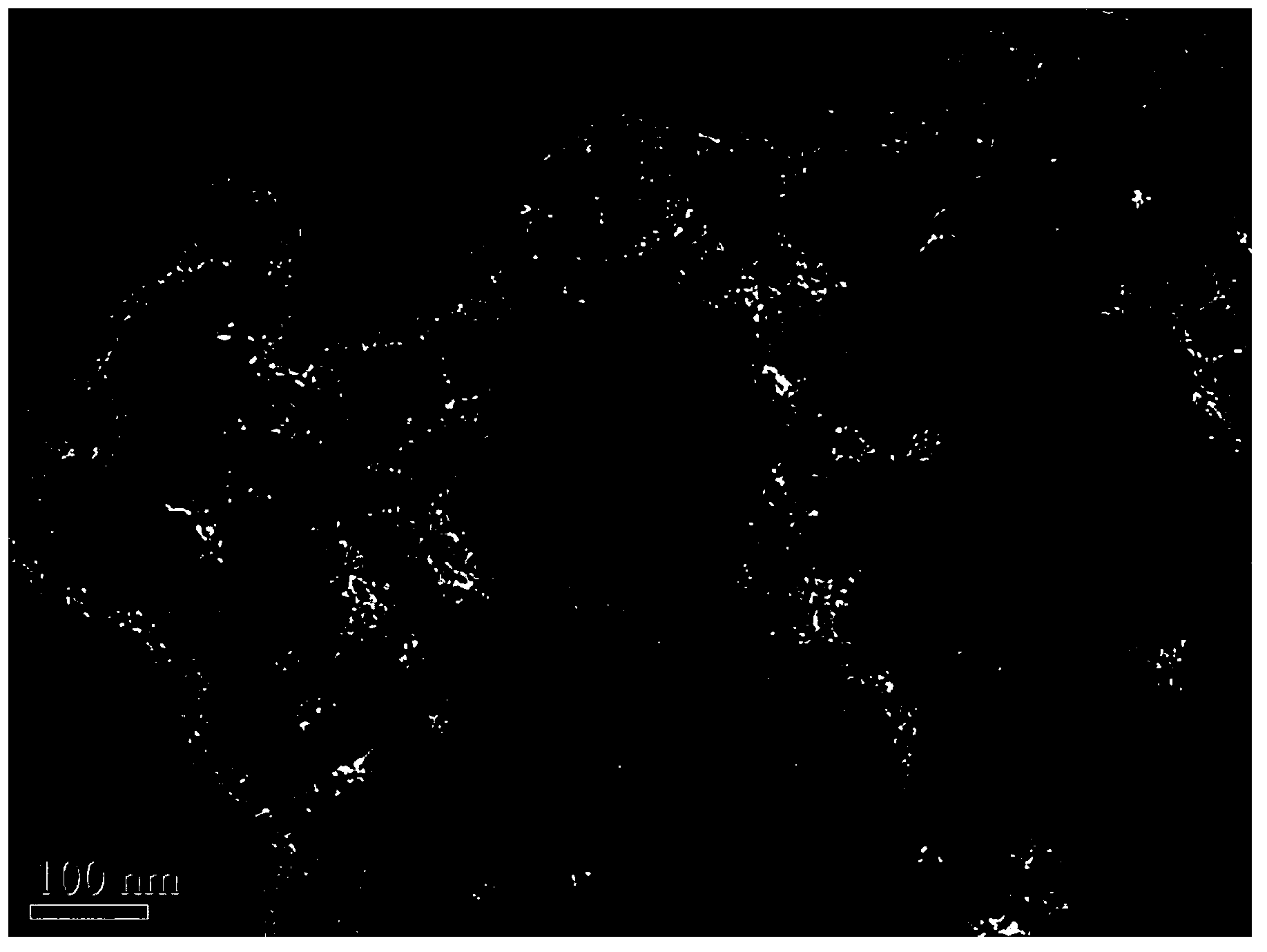

[0029] Embodiment 1: Preparation of hollow PMO type catalyst carrier

[0030] Dissolve 0.318 g (1.5 mmol) of (1S,2S)-(+)-N-p-toluenesulfonyl-1,2-diphenylethylenediamine (DPEN) in 10 mL of dichloromethane and keep its temperature at -5~0℃;

[0031] Then, 0.46mL (1.5mmol) (2-triethoxysilyl) ethylbenzenesulfonyl chloride was added dropwise to the dichloromethane solution of DPEN at a rate of 5-8 drops / min;

[0032] After reacting for 6 hours, the solvent was spin-dried to obtain (1S,2S)-(+)-N-p-p-(2-triethoxysilyl)ethylbenzenesulfonyl-1,2-diphenylethylenediamine, referred to as Ts-DPEN functionalized silicon source;

[0033] Dissolve 0.5g of F127 in 30mL of 2.0M hydrochloric acid solution, keep stirring at 15°C for 30min, and rotate at 1200r / min.

[0034] Then 0.5 g (4.17 mmol) of mesitylene and 2.5 g (33.6 mmol) of potassium chloride were added. After mechanical stirring at 1200r / min for two hours, 0.4g (0.82mmol) Ts-DPEN functionalized silicon source and 2.61g (7.38mmol) bi...

Embodiment 2

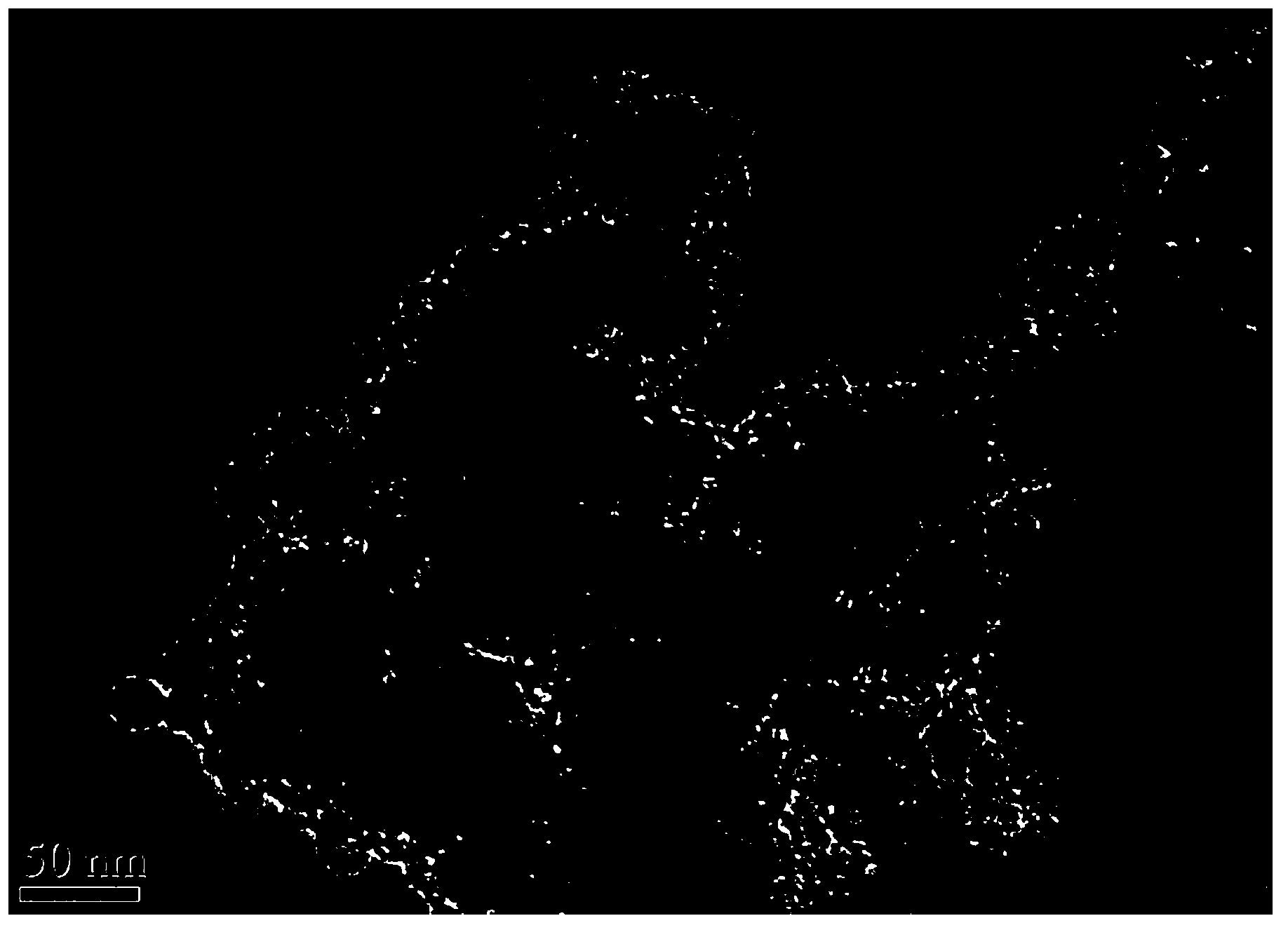

[0038] Embodiment 2: Preparation of hollow PMO type catalyst carrier

[0039] The preparation of the Ts-DPEN functionalized silicon source is the same as in Example 1.

[0040] Dissolve 0.6g of F127 in 30mL of 2.0M hydrochloric acid solution, keep stirring at 15°C for 30min, and rotate at 1200r / min.

[0041]Then 0.5 g (5.04 mmol) of mesitylene and 2.5 g (33.6 mmol) of potassium chloride were added. After mechanical stirring at 1200r / min for two hours, 0.4g (0.82mmol) Ts-DPEN functionalized silicon source and 2.61g (7.38mmol) bistriethoxysilylethane were added dropwise at a rate of 90-95 drops per minute. The Ts-DPEN functionalized silicon source was diluted with 0.5mL of dichloromethane.

[0042] Continue mechanical stirring for 24 hours, then sink at 100°C for 24 hours, perform suction filtration after the precipitation, and put the obtained white solid in a vacuum drying oven at 60-65°C to dry overnight.

[0043] Finally, it was subjected to Soxhlet extraction with ethano...

Embodiment 3

[0044] Embodiment 3: Preparation of hollow PMO type catalyst carrier

[0045] The preparation of the Ts-DPEN functionalized silicon source is the same as in Example 1.

[0046] Dissolve 0.5g of F127 in 30mL of 2.0M hydrochloric acid solution, keep stirring at 15°C for 30min, and rotate at 1200r / min.

[0047] Then 0.5 g (4.17 mmol) of mesitylene and 3.0 g (40.32 mmol) of potassium chloride were added. After mechanical stirring at 1200r / min for two hours, 0.4g (0.82mmol) Ts-DPEN functionalized silicon source and 2.61g (7.38mmol) bistriethoxysilylethane were added dropwise at a rate of 90-95 drops per minute. The Ts-DPEN functionalized silicon source was diluted with 0.5mL of dichloromethane.

[0048] Continue mechanical stirring for 24 hours, then sink at 100°C for 24 hours, perform suction filtration after the precipitation, and put the obtained white solid in a vacuum drying oven at 60-65°C to dry overnight.

[0049] Finally, it was subjected to Soxhlet extraction with etha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com