Sintered brick layered composite brick unloading method and device thereof

A technology for sintering bricks and driving devices, which is applied in the directions of transportation and packaging, stacking of objects, and de-stacking of objects, etc., can solve the problems of difficulty in unloading bricks by unloading bricks, difficulty in recruiting workers, and harsh working environment, and reduce the The effect of labor intensity, reducing production cost and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

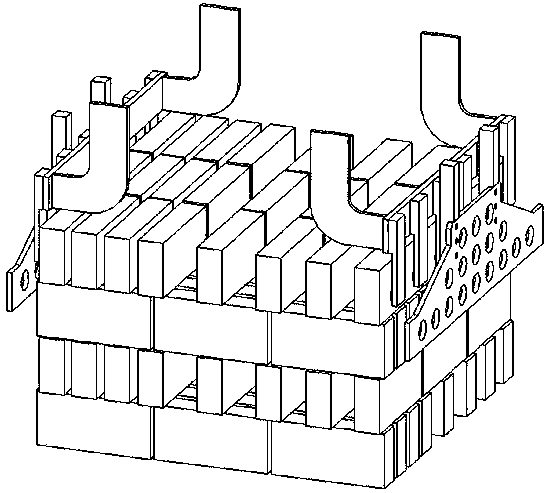

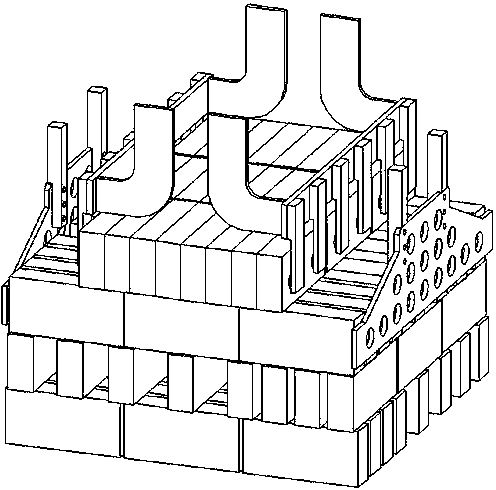

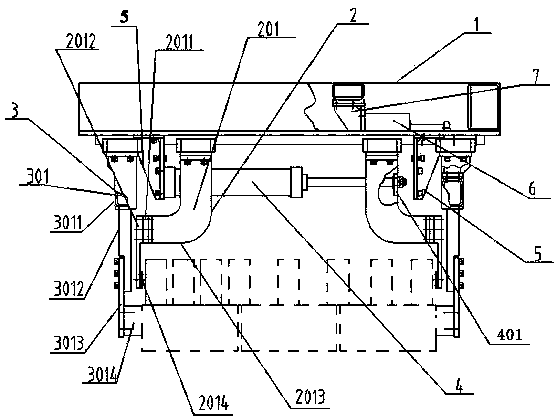

[0026] Such as Figure 3 to Figure 7 As shown, a layered composite unloading device for sintered bricks includes a hanger 1, a linear motion pair I, an upper gripper 2 set on the hanger 1 through the linear motion pair I, and is used to drive the upper gripper 2 to open And the driving device I for folding, also includes the lower gripping hand 3 located on the outside of the upper gripping hand 2 and the driving device II for driving the lower gripping hand 3 to open and retract, and the lower gripping hand 3 includes a linear motion pair I Or the linear motion pair II parallel to the linear motion pair I is set on two sets of lower clamp arm assemblies 301 on the hanger 1, the lower clamp arm assembly 301 includes the lower clamp arm 3011 and the lower clamp piece 3013 and the lower clamp arm is connected 3011 and the guide rod 301...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com