Method and apparatus used for preparing ammonium phosphate fertilizer from phosphoric acid sediment

A technology of ammonium phosphate and phosphoric acid, applied in ammonium orthophosphate fertilizers, alkaline orthophosphate fertilizers, fertilization devices, etc., can solve the problem of low total nutrients in fertilizers, increase the contact reaction area and speed, and simplify filter press washing process, the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

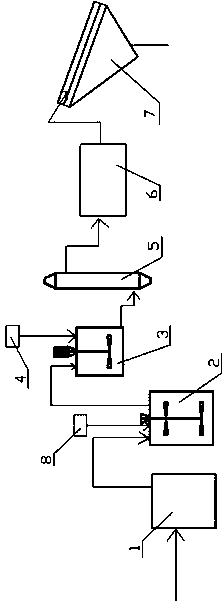

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the examples, and the following examples are intended to illustrate the present invention rather than further limit the present invention. Utilize phosphoric acid sediment to prepare the method for ammonium phosphate fertilizer, first embodiment, its steps are:

[0025] a. Dilute sulfuric acid is prepared by wet method in phosphate rock, and in P 2 O 5 Preparation of P by concentrating dilute phosphoric acid with a content of 18% 2 O 5 The concentrated phosphoric acid with a content of 44% concentrated phosphoric acid is placed in the clarification process, so that the phosphoric acid is stratified and precipitated to obtain P 2 O 5 Phosphoric acid sediment with a content of 30%;

[0026] b. In the mixing tank, according to the weight ratio of 2: 1, dilute phosphoric acid with a concentration of 18% and P 2 O 5 The phosphoric acid sediment with a content of 30% is mixed to obtain an interme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com