Flame retardation catalyst and supported flame retardation catalyst composed of same

An intumescent flame retardant and catalyst technology, which is applied in the field of flame retardant synergists, can solve problems such as deterioration of mechanical properties of materials, and achieve the effects of good mechanical properties, improved efficiency, and improved char-forming flame retardant efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

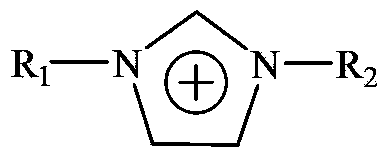

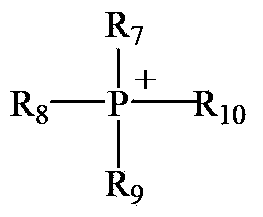

[0115] Disperse 1kg of natural montmorillonite in 10kg of deionized water to obtain a clay suspension; then disperse 10g of 1-butyl-3-methylimidazolium phosphomolybdate in 100g of ethanol to prepare a catalyst solution; then the dispersed The clay suspension is mixed with the catalyst solution, soaked for 6 hours, the solvent is distilled off, and dried to obtain a supported flame-retardant catalyst with a catalyst loading of 1 wt% of natural montmorillonite.

Embodiment 2

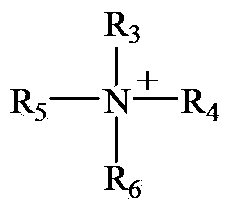

[0117] Disperse 100g of sodium montmorillonite in 1Kg of deionized water to obtain a clay suspension; then disperse 5g of didodecyldimethyl quaternary ammonium germanium tungstate in 50g of ethanol to prepare a catalyst solution; then disperse The good clay suspension is mixed with the catalyst solution, soaked for 18 hours, the solvent is distilled off, and dried to obtain a supported flame-retardant catalyst with a catalyst loading of 5 wt% of sodium-based montmorillonite.

Embodiment 3

[0119] The didodecanyl dimethyl quaternary ammonium germanium tungstate in embodiment 2 is replaced with 1-butyl-3-methylimidazole phosphomolybdate, and other experimental conditions are the same as in embodiment 2, and 1- Butyl-3-methylimidazolium phosphomolybdate is a supported flame-retardant catalyst with a loading capacity of 5 wt% of sodium montmorillonite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com