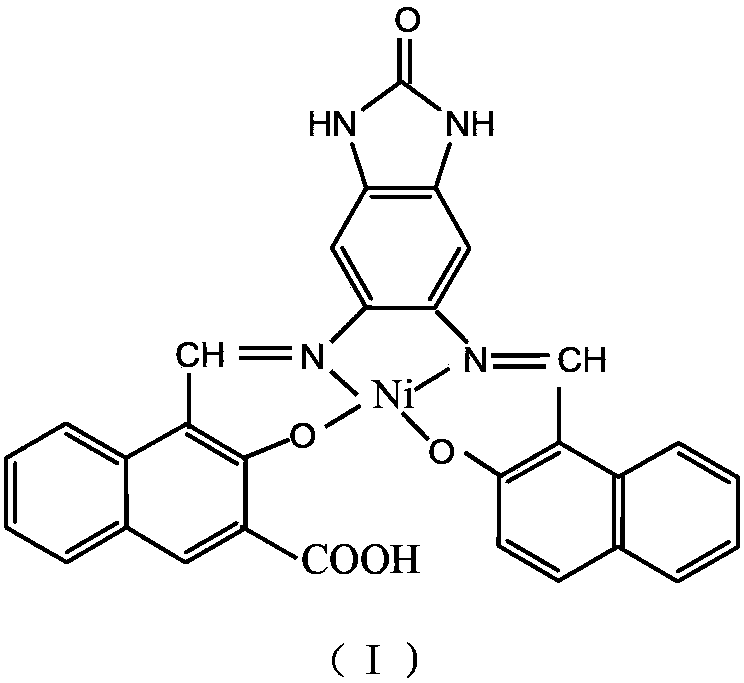

Novel bisazo methenyl nickel complexing solvent dye containing benzimidazolone ring, and preparation method and application of complexing solvent dye

A technology of benzimidazolone ring and bisazomethine is applied in the field of novel bisazomethine nickel complex solvent dye and its preparation, which can solve problems such as poor compatibility and inapplicability, and achieve excellent fastness performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

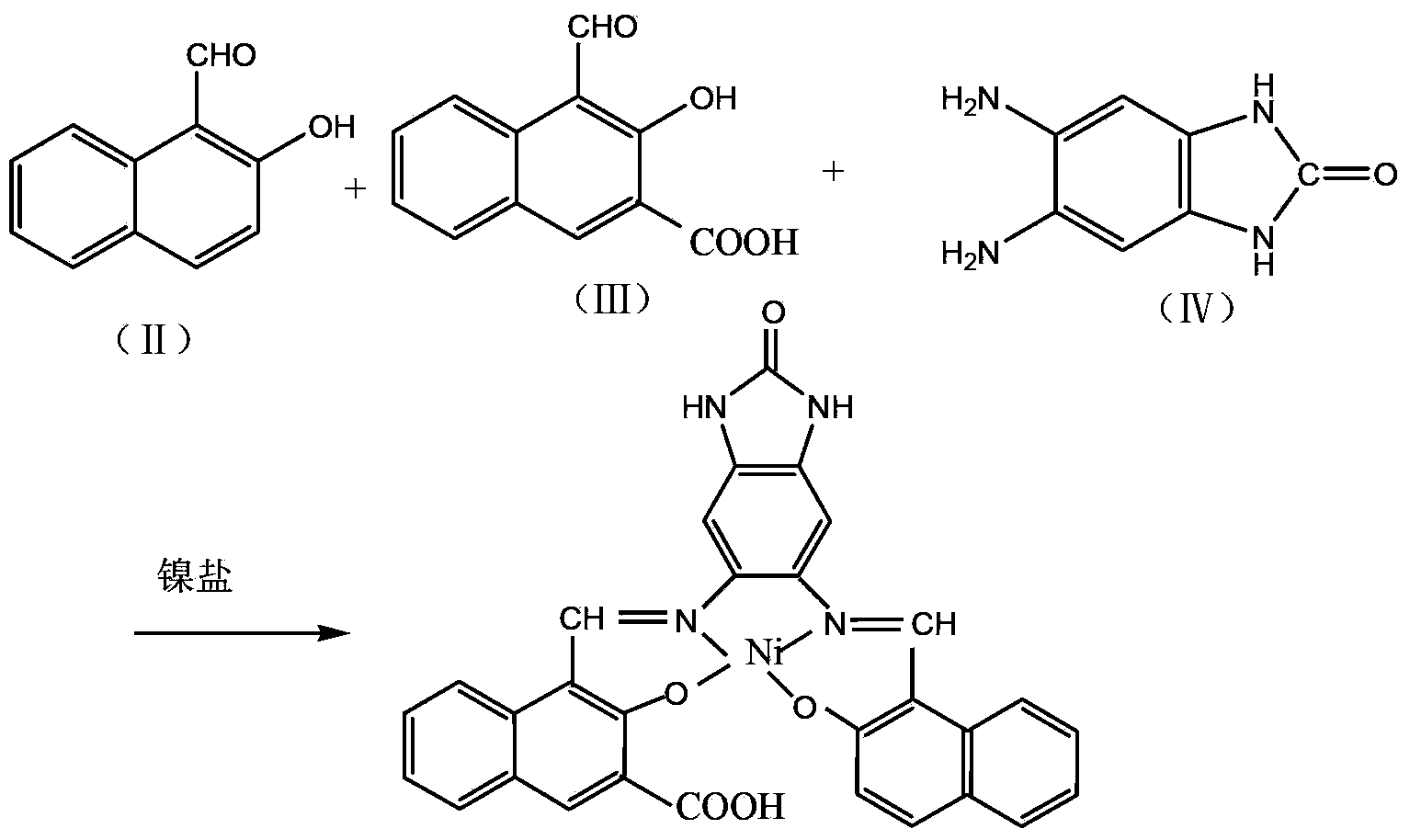

Method used

Image

Examples

Embodiment 1

[0024] Example 1. In a 500ml four-neck bottle, add 160 grams of water, start stirring, carefully add 8 grams of industrial potassium hydroxide, raise the temperature to 75°C, blow in nitrogen, and then add 4.1 grams (0.025 moles) of 5,6-Di Aminobenzimidazolone, 4.3 g (0.025 mol) 2-naphthol-1-carbaldehyde, after 15 minutes of reaction, add 5.4 g (0.025 mol) 3-carboxylic acid-2-hydroxy-1-naphthaldehyde and 0.01 g hyperdisperse Agent BYK-W996, continue to stir for 15 minutes, add 17 grams of 30% hydrochloric acid, the material turns dark red, stir at 75-80 ° C for 30 minutes, add 7 grams (0.028 moles) of nickel acetate tetrahydrate dissolved in 35 grams of hot water solution, heat the material carefully to 95-100°C, keep it warm for 18 hours, cool down to 60°C, filter, wash with 80°C hot water until the filtrate is neutral, and dry the filter cake at 105°C to obtain 13.8 grams of dark red powder, weight Yield 96.3%. After the sample was recrystallized by DMF, the color was deep ...

Embodiment 2

[0025] Example 2. In a 500ml four-necked bottle, add 160 grams of water, start stirring, carefully add 8 grams of industrial potassium hydroxide, raise the temperature to 75°C, blow in nitrogen, add 4.1 grams (0.025 moles) of 5,6-diamino Benzimidazolone, 4.3 g (0.025 mol) 2-naphthol-1-carbaldehyde and 5.4 g (0.025 mol) 3-carboxylic acid-2-hydroxy-1-naphthaldehyde and 0.01 g hyperdispersant BYK-W996, 5 Minutes later, add 17 grams of 30% hydrochloric acid, the material turns dark red, stir at 75-80°C for 2 hours, add 7.1 grams (0.03 moles) of nickel chloride hexahydrate dissolved in 50 grams of hot water, stir for 30 minutes, and Transfer the material to a 500ml glass pressure reactor, carefully raise the temperature to 110°C, the pressure is about 1.5kg / cm2, keep it warm for 6 hours, cool down to 80°C, filter the discharge, wash with 80°C hot water until the filtrate is neutral, filter The cake was dried at 105° C. to obtain 14.0 g of dark red powder, with a weight yield of 97....

Embodiment 3

[0026] Example 3. In a 500ml four-necked bottle, add 100 grams of water, start stirring, carefully add 4 grams of industrial potassium hydroxide, raise the temperature to 80°C, blow in nitrogen, add 4.1 grams (0025 moles) of 5,6-diamino Benzimidazolone, 0.01 g emulsifier Emulgen A-60, a solution of 4.3 g (0.025 mol) 2-naphthol-1-carbaldehyde dissolved in 20 g ethylene glycol monomethyl ether, 5.4 g (0.025 mol) was added after 2 minutes ) 3-carboxylic acid-2-hydroxyl-1-naphthaldehyde was dissolved in a solution of 30 grams of ethylene glycol monomethyl ether, 8.5 grams of 30% hydrochloric acid was added after 5 minutes, the material turned dark red, stirred for 1 hour, and 7 grams of (0.028 mol) nickel acetate tetrahydrate dissolved in 35 grams of hot water solution, the material is heated to 98-100 ° C, kept for 8 hours, cooled to 60 ° C, filtered, washed with 80 ° C hot water until the filtrate is neutral, and the filter cake Dry at 105° C. to obtain 13.2 g of dark red powder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com