High-temperature molten salt electrolysis rare earth metal slotting device and method

A rare earth metal, high-temperature molten salt technology, applied in the direction of electrolysis components, electrolysis process, etc., can solve the problems of siphon shape without thermal insulation measures, difficult to clean, high labor intensity, etc., to overcome the labor intensity of workers, avoid sealing difficulties, improve The effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following describes the implementation of the present invention in detail with reference to the drawings and embodiments.

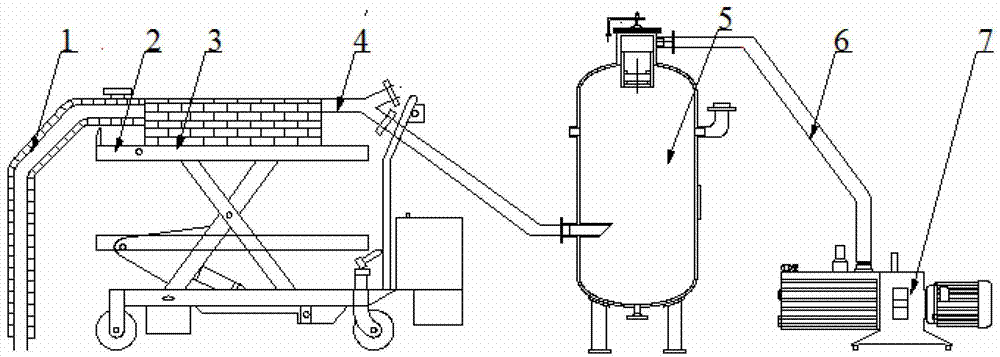

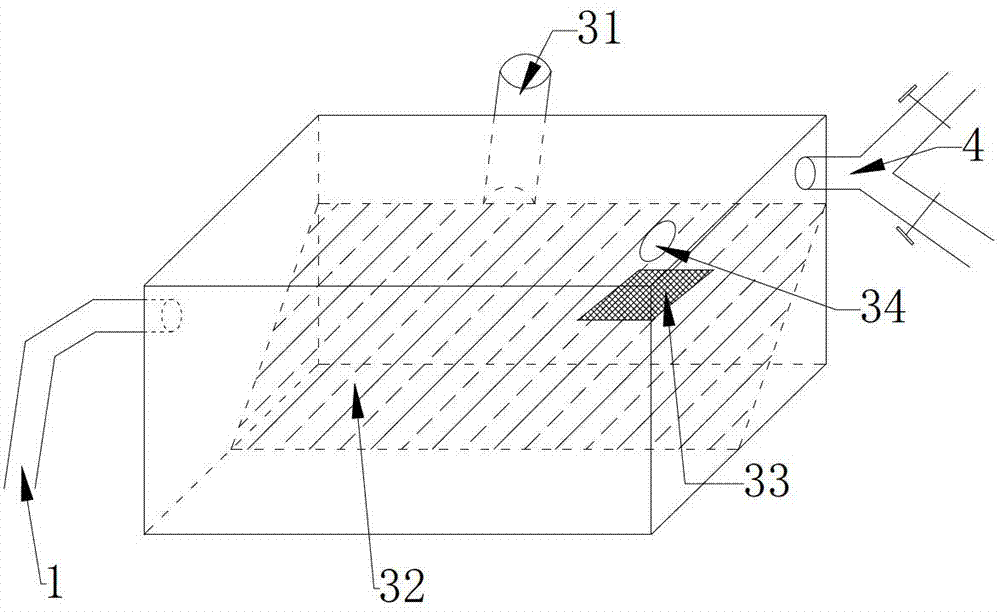

[0025] Such as figure 1 As shown, a high-temperature molten salt electrolysis rare earth metal outgoing device includes a vacuum liquid storage bag 3 with a metal liquid outlet 31. The vacuum liquid storage bag 3 is fastened to the flip-type lifting platform truck 2, and the vacuum liquid storage bag 3 One end is connected to the siphon tube 1, and the other end is connected to the vacuum buffer tank 5 through the metal bellows 4, and the vacuum buffer tank 5 is connected to the vacuum pump 7 through the vacuum connecting tube 6. The siphon tube 1 is a straight rounded siphon tube, which is made of titanium-based material that has high temperature resistance, corrosion resistance, low thermal conductivity, easy production, and does not affect product quality. The depth of the siphon tube 1 inserted into the molten salt in the electrolytic tank can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com