Aluminum heat radiating module of LED (Light Emitting Diode)

A technology of aluminum heat dissipation and LED chips, which is applied in cooling/heating devices of lighting devices, lighting and heating equipment, lighting devices, etc., can solve the problems of complex manufacturing process, poor heat conduction effect, low production efficiency, etc., and achieve heat dissipation effect Good, high production efficiency, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

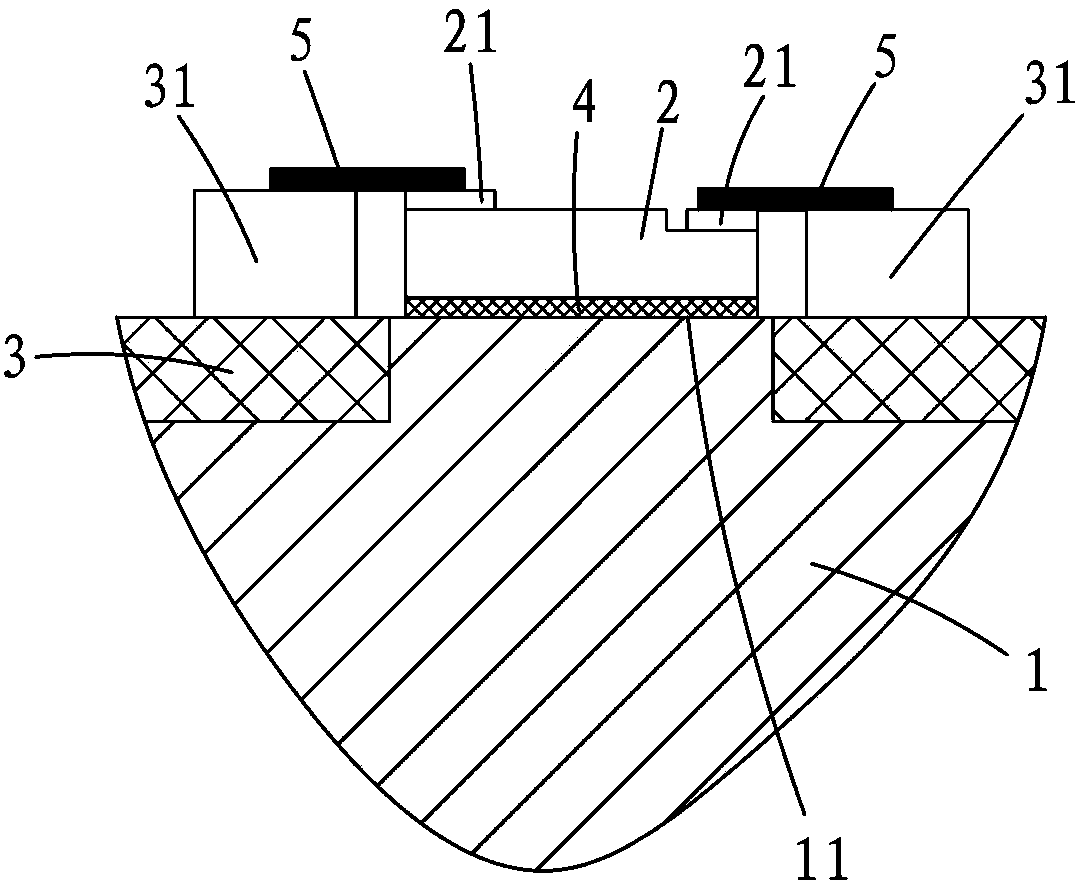

[0017] Such as figure 1 As shown, an aluminum heat dissipation module for LEDs includes an aluminum heat sink 1, an LED chip 2, and an ordinary PCB board 3;

[0018] There are circuit pads 31 corresponding to the two electrodes 21 of the LED chip 2 on the common PCB board 3;

[0019] A heat conduction surface 11 is provided on the aluminum heat sink 1, and a concave surface for placing an ordinary PCB board 3 is arranged adjacent to the heat conduction surface 11; the ordinary PCB board 3 is placed in the concave surface of the aluminum heat sink 1; the insulating surface of the LED chip 2 is The adhesive glue 4 is bonded to the corresponding position of the heat conducting surface 11 of the aluminum heat sink 1 ; the two electrodes 21 of the LED chip 2 and the two circuit pads 31 on the ordinary PCB 3 are correspondingly connected by conductive wires 5 .

[0020] In the aluminum heat dissipation module of a kind of LED of the present invention, because the LED chip directly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com