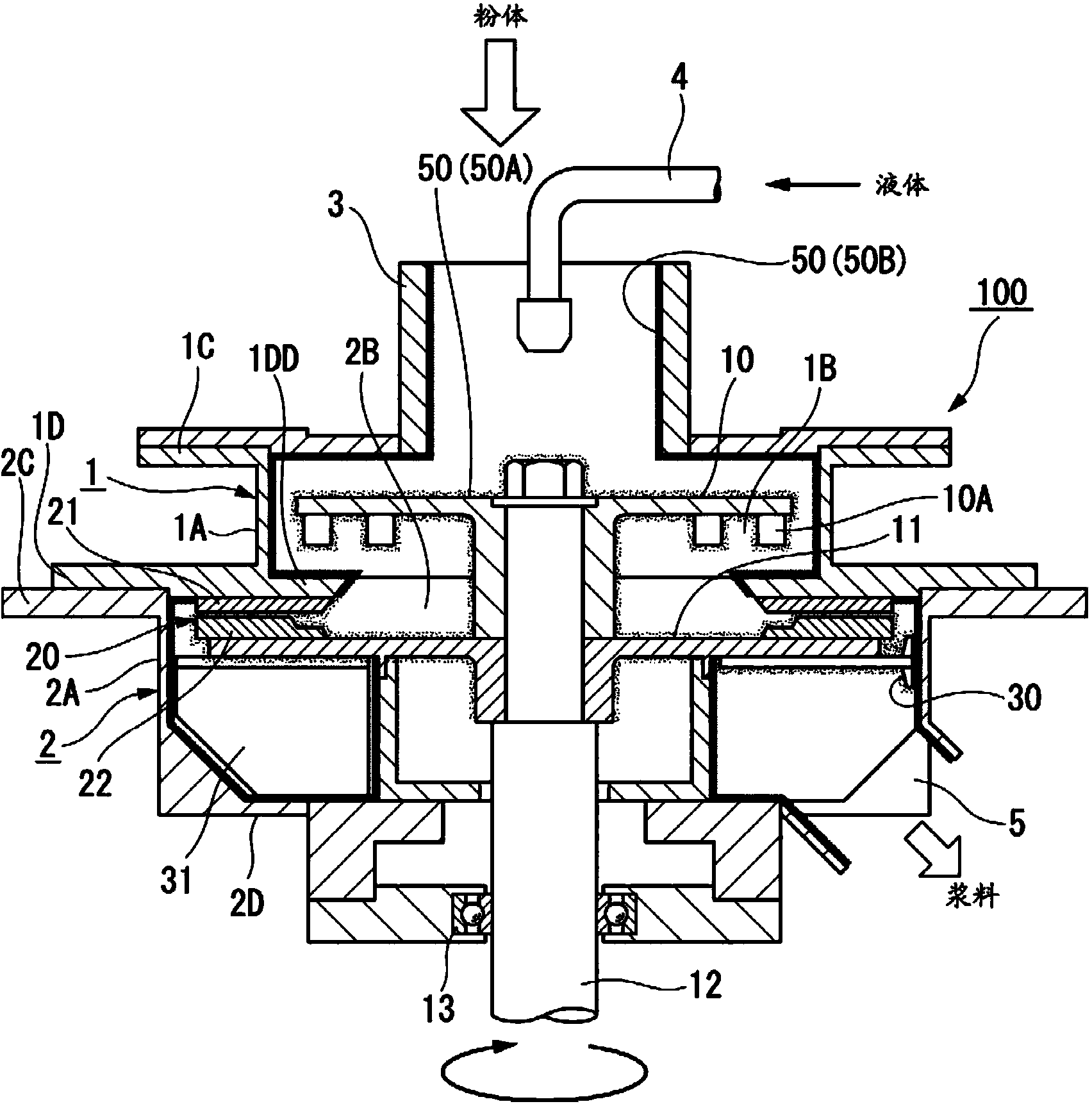

Continuous kneading device

A kneading and liquid mixing technology, which is applied to mixers with rotating agitation devices, mixers, mixing methods, etc., can solve the problems of poor discharge performance and high slurry viscosity, and achieve reduced viscosity and good mixing performance , good discharge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0064] First, prepare aluminum (JIS A2014) and stainless steel (JIS SUS304) as base materials, and prepare the base material itself without coating, the base material with TiN coating on the surface of the base material, and the Substrates coated with TiCN, substrates coated with DLC, substrates coated with PEEK, substrates coated with PTFE, and measured coefficient of kinetic friction.

[0065] In addition, the dynamic friction coefficient was measured under the condition that a load of 5 to 20 N was applied to a cemented carbide ball with a diameter of 6 mm at room temperature in a ball-on-disk friction test using a friction and wear tester manufactured by CSEM Corporation.

[0066] show the result in Image 6 . As can be seen from the figure, the dynamic friction coefficient of aluminum is 0.6, and that of stainless steel is 0.5. On the other hand, when these substrates are coated, the TiN coating is 0.4, the TiCN coating is 0.3, and the DLC coating is 0.4. Coefficient o...

Embodiment 2

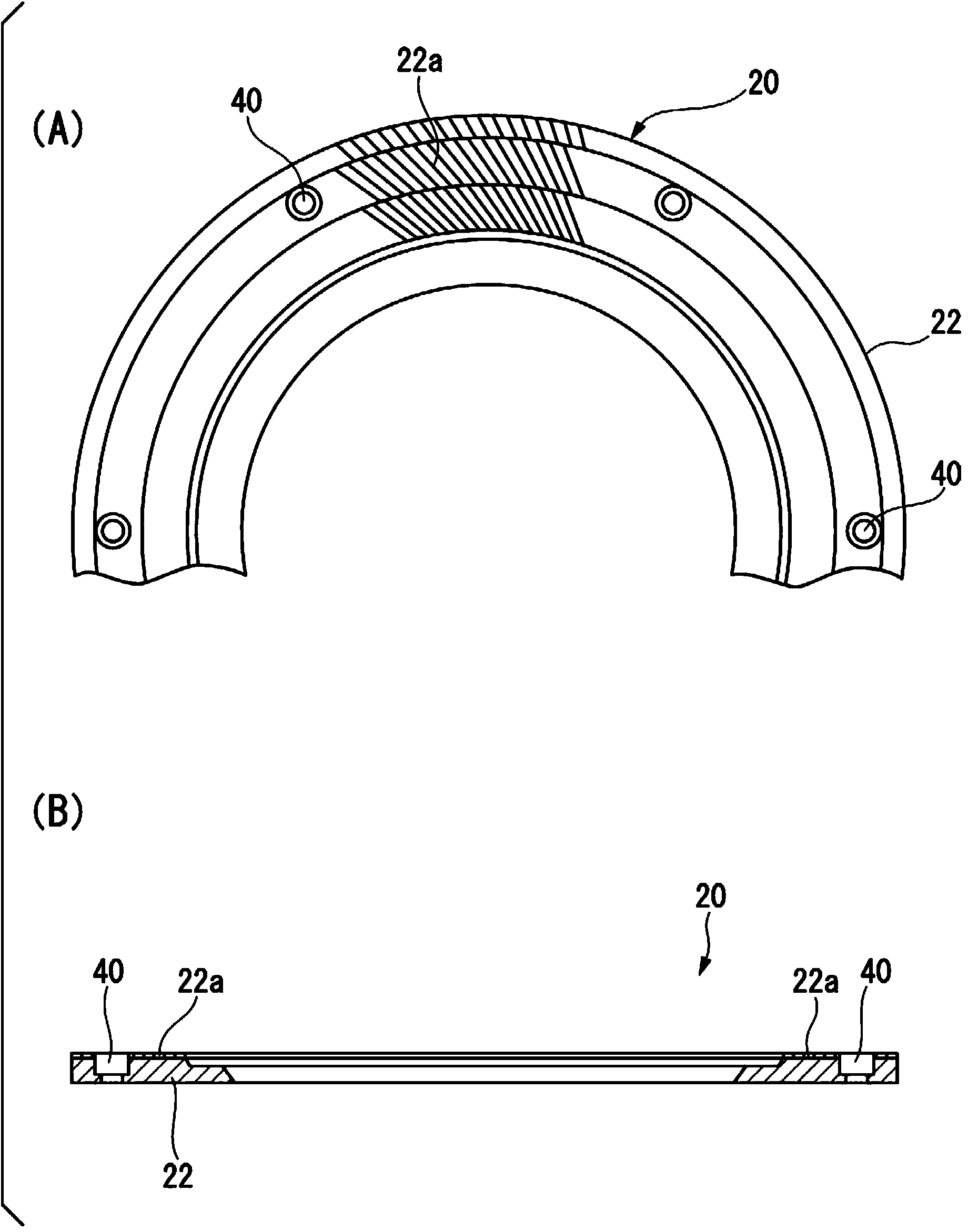

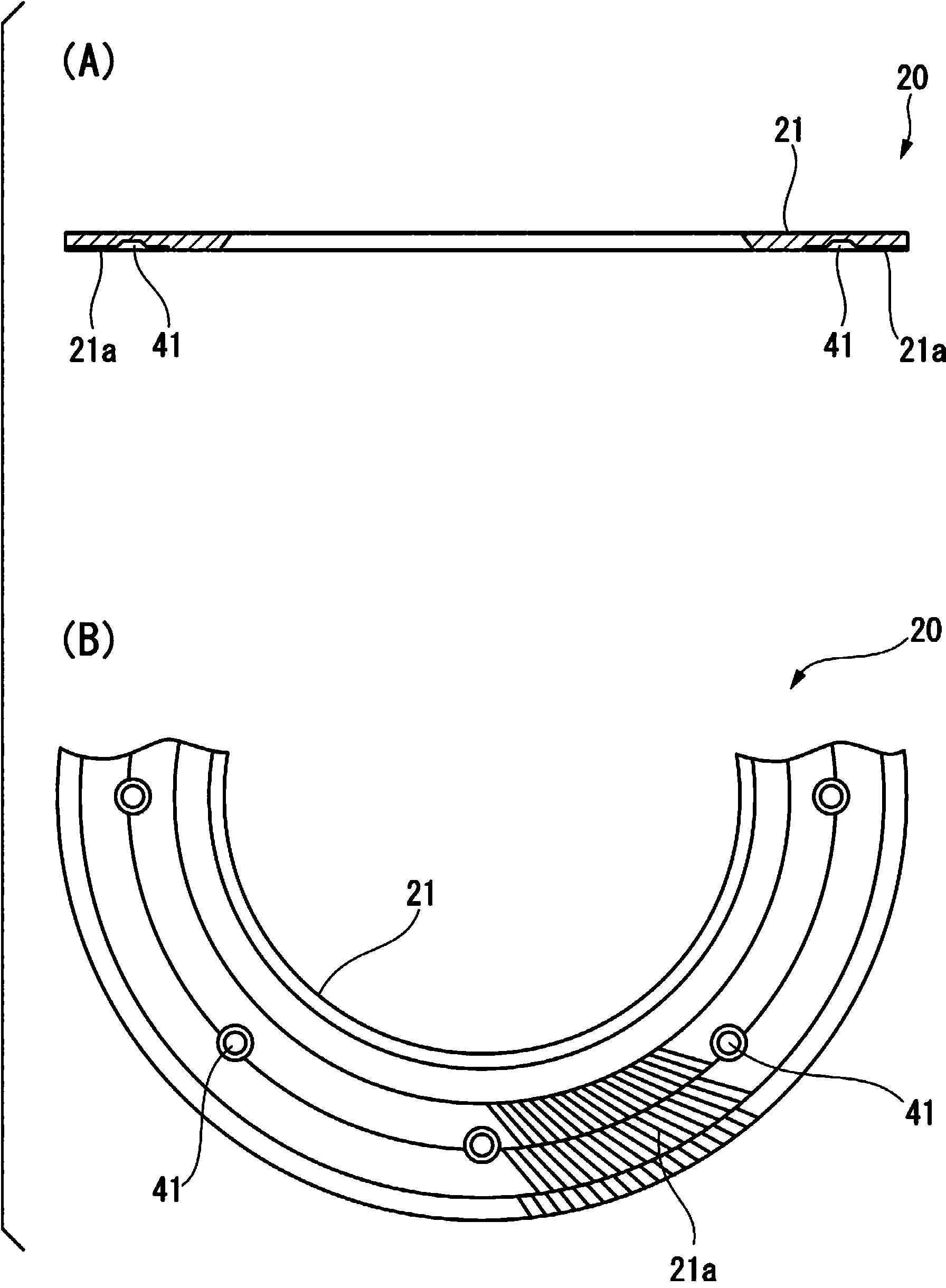

[0070] Example 2 is an example of kneading the powder raw material, that is, quartz powder with an average particle diameter of 0.8 μm on a volume basis, and the liquid raw material, that is, ion-exchanged water, using an apparatus having the same apparatus structure as that of Example 1. Embodiment 3 is to use a PTFE coating (material) to cover the surfaces of the rotating kneading discs 10, 11, the surface of the scraping blade 31, the inner surface of the upper shell 1, and the inner surface of the lower shell 2 for mixing powder raw materials. That is, an example of quartz powder and liquid raw material, namely ion-exchanged water. Example 4 is to knead powder raw materials using a device that covers the surfaces of the rotating kneading discs 10 and 11, the surface of the scraping blade 31, the inner surface of the upper shell 1, and the inner surface of the lower shell 2 respectively with PEEK coating (material) That is, an example of quartz powder and liquid raw materia...

Embodiment 7

[0071] Embodiment 7 uses DLC coating (material) to cover the surfaces of the rotating mixing discs 10 and 11 and the surface of the scraping blade 31 respectively, and covers the inner surface of the upper shell 1 and the lower shell 2 with a PEEK coating (material). An example of kneading powder raw material, namely quartz powder, and liquid raw material, namely ion-exchanged water, on the inner surface of the device. Example 8 uses TiCN coating (material) to respectively cover the surfaces of the rotating mixing discs 10 and 11, the surface of the scraping blade 31, and respectively covers the inner surface of the upper shell 1 and the lower shell 2 with a PEEK coating (material). The device on the inner surface is an example of kneading quartz powder, which is a powder raw material, and ion-exchanged water, which is a liquid raw material. Example 9 covers the surfaces of the rotating mixing discs 10 and 11 and the scraping blade 31 with a TiN coating (material), and covers ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com