Method for adsorption treatment of cesium-containing wastewater through using heat modified attapulgite adsorbent

A technology of attapulgite and adsorbent, which is applied in the field of thermally modified attapulgite adsorbent to treat cesium-containing wastewater, which can solve the problems of many types of raw materials and complicated preparation processes, and achieve simple operation process, strong economy, and adsorption conditions less demanding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The purified attapulgite was placed in a muffle furnace, fired at 400° C. for 1.5 hours, and the modified attapulgite adsorbent was obtained.

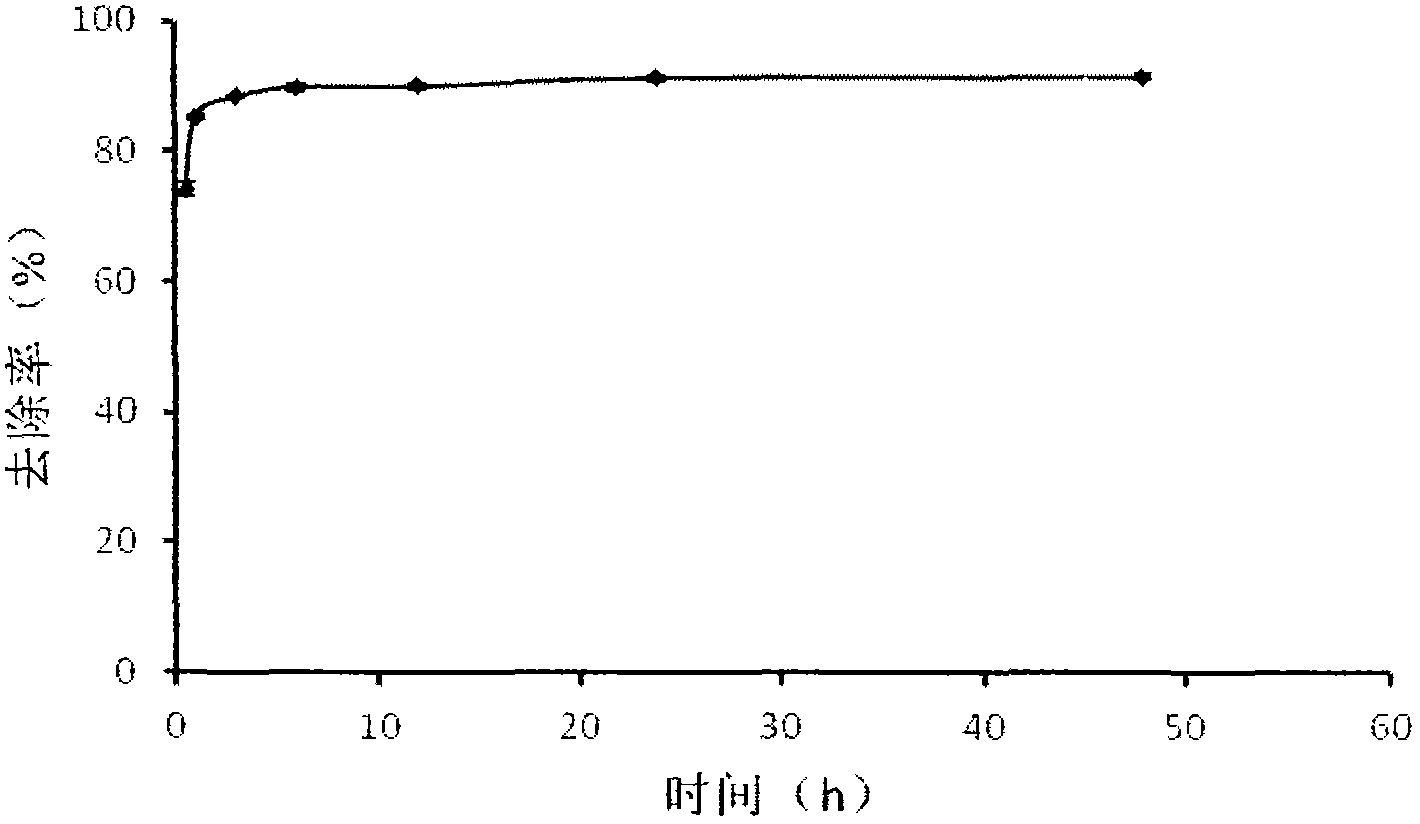

[0045] Accurately weigh 1.5000g (±0.0005g) of thermally modified attapulgite adsorbent, place it in a 250mL conical flask with a stopper, add 30mL of cesium chloride solution with a concentration of 100mg / L, and place it in a constant temperature oscillator , oscillating at a rate of 150 r / min at a temperature of 25°C, at this time the mass ratio of cesium in the cesium-containing wastewater to the adsorbent is 1:500. The supernatant was taken at 0.5h, 1h, 3h, 6h, 6h, 24h, and 48h respectively, and the concentration of residual cesium was tested by an inductively coupled plasma emission mass spectrometer (ICP-MS). Three groups of parallel experiments were set for each experiment, and the results were expressed as arithmetic mean values, and standard deviations were calculated to ensure test accuracy. The calculated removal rate...

Embodiment 2

[0049] The thermally modified attapulgite adsorbent was prepared in the same way as in Example 1.

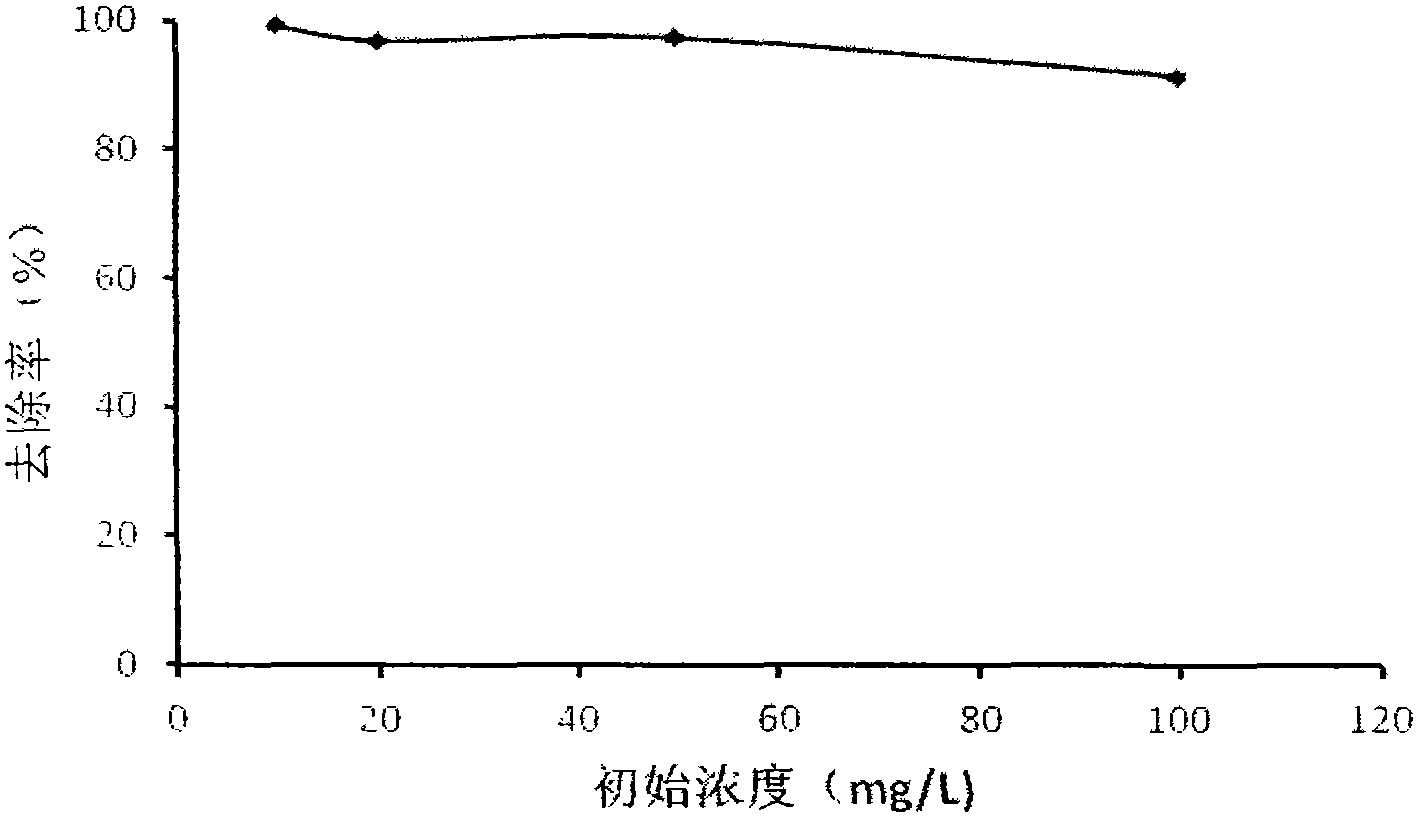

[0050] Accurately weigh 0.5000g (±0.0005g) of the thermally modified attapulgite adsorbent, place it in a 250mL conical flask with a stopper, add 10mL of cesium chloride solutions with concentrations of 10, 20, 50, and 100mg / L respectively , placed in a constant temperature oscillator, oscillating at a rate of 150r / min at a temperature of 25°C for 48h to adsorption equilibrium, at this time the mass ratios of cesium in the cesium-containing wastewater to the adsorbent are 1:5000, 1:2500, 1: 1000, 1:500. The supernatant was taken to measure the concentration of residual cesium with an inductively coupled plasma emission mass spectrometer (ICP-MS). Three parallel groups were set for each experiment, and the results were expressed as arithmetic mean values, and the standard deviation was calculated to ensure test accuracy. After calculation, the adsorption and removal rates of ces...

Embodiment 3

[0053] The thermally modified attapulgite adsorbent was prepared in the same way as in Example 1.

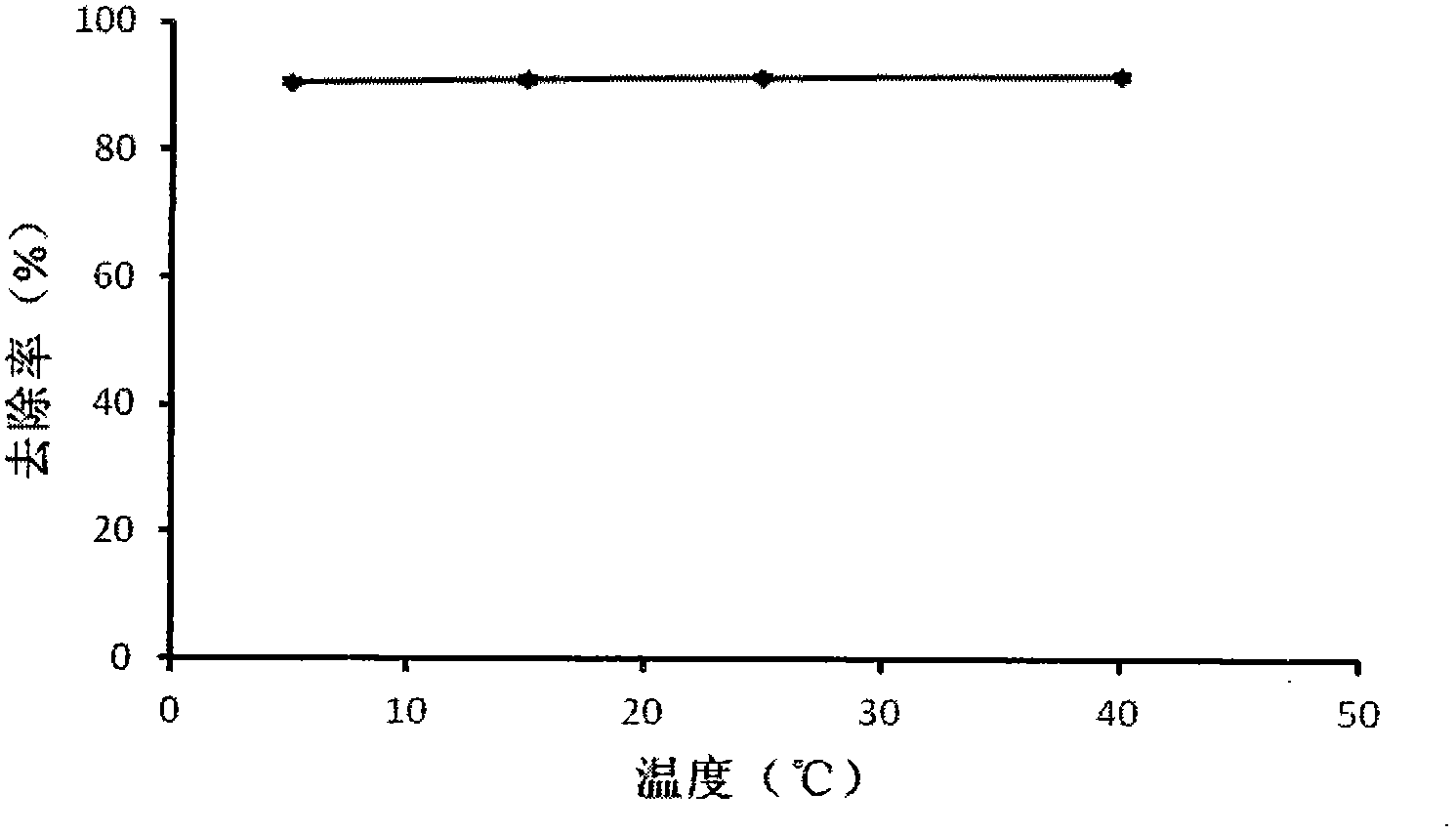

[0054] Accurately weigh 0.5000g (±0.0005g) of the thermally modified attapulgite adsorbent, put it in a 250mL conical flask with a stopper, add 10mL of cesium chloride solution with a concentration of 100mg / L, and place it in a constant temperature oscillator , at 5, 15, 25, and 40°C, respectively, at 5, 15, 25, and 40°C, oscillating at a rate of 150r / min for 24h to reach adsorption equilibrium. At this time, the mass ratio of cesium in the cesium-containing wastewater to the adsorbent is 1:500. The supernatant was taken to measure the concentration of residual cesium with an inductively coupled plasma emission mass spectrometer (ICP-MS). Three parallel groups were set for each experiment, and the results were expressed as arithmetic mean values, and the standard deviation was calculated to ensure test accuracy. After calculation, the adsorption and removal rates of cesium are 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com