Laser modification treatment process of titanium oxide photocatalytic film

A technology of photocatalytic film and treatment process, applied in the direction of physical/chemical process catalyst, chemical/physical process, catalyst activation/preparation, etc., can solve the problems of difficult and effective wide application, single application field, complex raw materials, etc., and achieve improvement. The effect of photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

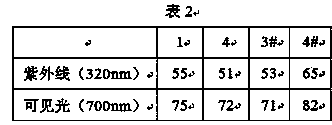

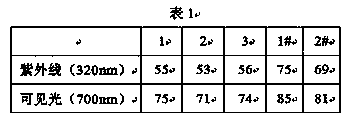

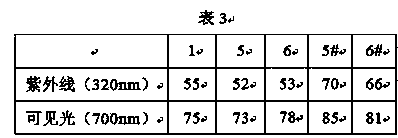

Examples

Embodiment 1

[0023] (1) Mix titanium tetraisopropoxide and absolute ethanol with a molar ratio of 1:6 in a container, and use electromagnetic stirring for 20 minutes to obtain liquid A;

[0024] (2) Add diethanolamine dropwise to liquid A, the amount of which is 0.2 times the molar amount of titanium tetraisopropoxide, and then electromagnetically stir the mixed solution for 40 minutes to obtain liquid B;

[0025] (3) Add acetic acid dropwise to liquid B, the amount of which is 0.35 times the molar amount of titanium tetraisopropoxide, and then electromagnetically stir the mixed solution for 4 hours to obtain a sol;

[0026] (4) Using ceramics as the substrate, the substrate was ultrasonically cleaned with acetone for 10 minutes, then dried at 110°C for 10 minutes while blowing N 2 , then drop the sol onto the substrate and spin-coat at a speed of 2000rpm for 1.5min to obtain a wet film;

[0027] (5) Place the wet film-coated ceramic substrate in a muffle furnace to raise the temperature ...

Embodiment 2

[0031] The main difference from Example 1 is that the molar ratio of titanium tetraisopropoxide and absolute ethanol is 1:7.

Embodiment 3

[0033] The main difference from Example 1 is that the molar ratio of titanium tetraisopropoxide and absolute ethanol is 1:8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com