Preparation method of high-purity tantalum powder with centralized controllable particle size distribution

A particle size distribution and tantalum powder technology, applied in the field of high-purity tantalum powder, can solve the problems of insufficient particle size distribution and incomplete classification of tantalum powder, and achieve centralized and controllable particle size distribution, prevent surface adhesion, and clean particles. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

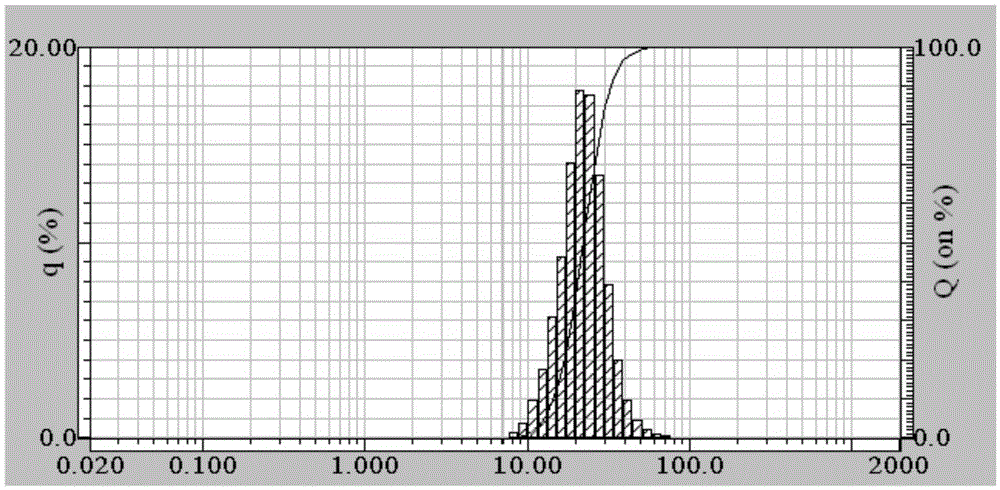

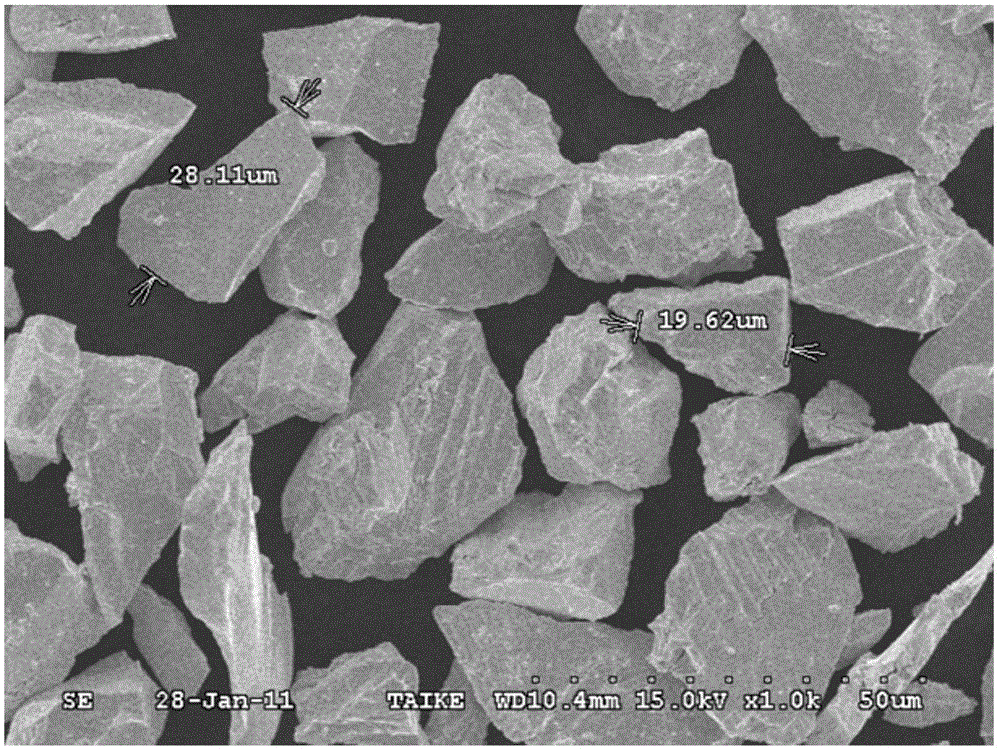

[0026] Example 1 The high-purity tantalum ingot is heated to 700°C in a hydrogenation furnace, and hydrogenated with hydrogen with a purity of 99.999% to form tantalum chips. Then put 1.6 kg of tantalum chips into the tantalum crucible of the pulverizer to beat and pulverize, and the pulverization time is 2 minutes. The pulverized tantalum powder is vibrated and sieved, and the analysis sieve mesh is 325 mesh. Put 0.8 kg of tantalum powder under the sieve into a tantalum cup, inject 600 ml of absolute alcohol, and carry out high-frequency oscillation classification. The classification is repeated several times. After classification, the tantalum The powder was dried in vacuum at low temperature at 150°C, and finally the tantalum powder was heated to 800°C in a hydrogenation furnace for dehydrogenation. The chemical composition analysis of the tantalum powder after dehydrogenation is shown in Table 1, and the particle size distribution is as follows: figure 1 , scanning elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com