Method for preparing composite nanometer film

A nano-film and conductive polymer technology, applied in the field of manufacturing composite nano-films, can solve the lack of sufficient understanding of the distribution order and looseness of GO materials, the low controllability of the thickness of conductive polymers, and the difficulty in forming ultra-thin GO materials. Conductive polymer layer and other problems, to achieve the effect of easy operation, good flexibility, reasonable and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

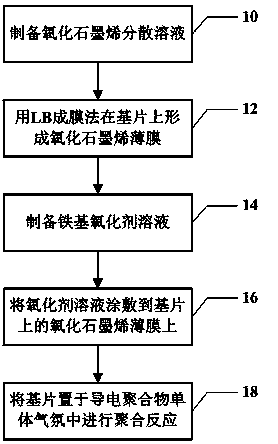

[0050] ①Disperse carboxylated graphene oxide in N,N-dimethylformamide, the concentration of graphene oxide is 3mg / ml to form a graphene oxide dispersion for LB film preparation; dissolve ferric chloride in In ultrapure water, the concentration of ferric chloride is 25mg / ml, forming an oxidizing agent solution for spin-coating film preparation;

[0051] ② Use a micro-injector to extract 500 μl of graphene oxide / N,N-dimethylformamide solution and drop it on the surface of the ultrapure aqueous solution in the LB membrane tank, and wait for N,N-dimethylformamide to volatilize for 40 minutes (minutes) Then start to press the film, and the graphene oxide film has been formed at the gas / liquid interface at this time;

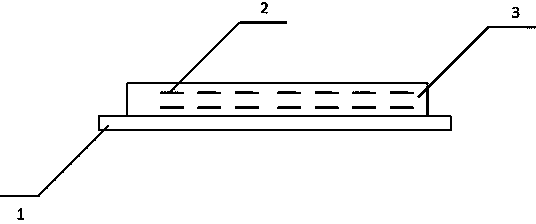

[0052] ③Control the sliding barrier of the LB film equipment to compress the graphene oxide film at a speed of 2mm / min to a film pressure of 12mN / m, and transfer the graphene oxide film to the ITO substrate by vertical film formation with a film formation rate of 0.1m...

Embodiment 2

[0057] In this example, the conductive polymer is polypyrrole, and the preparation process of the flexible composite nano-film is similar to Embodiment 1, so as to obtain a composite nano-film structure in which a single layer of graphene oxide is distributed in polypyrrole.

example 3

[0059] In this example, the conductive polymer is polyaniline, and the preparation process of the flexible composite nano-film is similar to Embodiment 1, so as to obtain a composite nano-film structure in which a single layer of graphene oxide is distributed in polyaniline.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com