Formula of environmental-friendly rubber and preparation method thereof

An environmentally friendly adhesive and formula technology, applied in tire parts, transportation and packaging, special tires, etc., can solve problems such as soil, biological hazards, harm to the human body, and pollute the environment, achieve thorough mutual dispersion, complete response, and improve wear resistance. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Raw material components: 90 parts of emulsion polystyrene butadiene rubber, 36 parts of solution polystyrene butadiene rubber, 70 parts of high structure dispersed silica, 2.5 parts of dispersant fatty acid zinc soap, 1 part of chemical antioxidant N-phenyl-N`- Cyclohexyl p-phenylenediamine and 1 part of microcrystalline wax, 4 parts of active agent are 3 parts of ZnO and 1 part of stearic acid SA, 2 parts of vulcanizing agent S, 2 parts of accelerator sulfenamide CZ and 15 parts of environmental protection oil SIS .

[0034] The preparation process is carried out in a 270L internal mixer:

[0035] Step 1: Add solution polystyrene butadiene rubber, emulsion polystyrene butadiene rubber, anti-aging agent, active agent, and dispersant for mixing. The mixing time is 20~30 seconds, the mixing temperature is 80~100°C, and the pressure is 0.56~0.64Mpa ;

[0036] Step 2: Put in high-structure carbon black and mix for 30-40 seconds, the mixing temperature is 90-120°C, a...

Embodiment 2

[0044] Raw material components: 100 parts of emulsion polystyrene butadiene rubber, 45 parts of solution polystyrene butadiene rubber, 60 parts of high structure dispersed silica, 3.5 parts of dispersant fatty acid zinc soap, 1 part of antioxidant N-N`-diphenyl-p-phenylene Diamine and 1 part of microcrystalline wax, 2.5 parts of active agent ZnO and 1 part of stearic acid SA, 3.5 parts of vulcanizing agent S, 1.5 parts of accelerator guanidine D and 24 parts of environmental protection oil TPE.

[0045] The preparation method is the same as in Example 1.

Embodiment 3

[0047]Raw material components: 110 parts of emulsion polystyrene butadiene rubber, 50 parts of solution polystyrene butadiene rubber, 75 parts of high structure dispersed silica, 1.5 parts of dispersant fatty acid zinc soap, 1.5 parts of antioxidant 4.4 a pair (2.2-dimethylbenzyl Base) diphenylamine and 1.5 parts of microcrystalline wax, 4.5 parts of active agent ZnO and 1 part of stearic acid SA, 3 parts of vulcanizing agent S, 3 parts of accelerator dithiocarbamate ZDMC and 20 parts of environmental protection oil TPR.

[0048] The preparation method is the same as in Example 1.

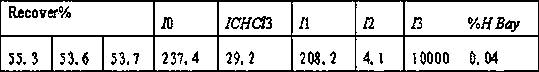

[0049] Testing standard:

[0050] Main Specifications:

[0051] According to the requirements of Item 50 of Annex XVII of the EU REACh regulation (1907 / 2006 / EC), the content of hydrogen in the extender oil contained in the tread of brand-new tires or retreaded tires produced after January 1, 2010 should not exceed 0.35%

[0052] Inspection basis: ISO 21461:2009(E)

[0053] The product sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com