Low-temperature-resistant toughened nylon material and preparation method thereof

A nylon composite material with low temperature resistance technology, applied in the field of polymer processing, can solve the problems of not providing excellent ductility of the material, and achieve the effect of broad market application prospects, low cost, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

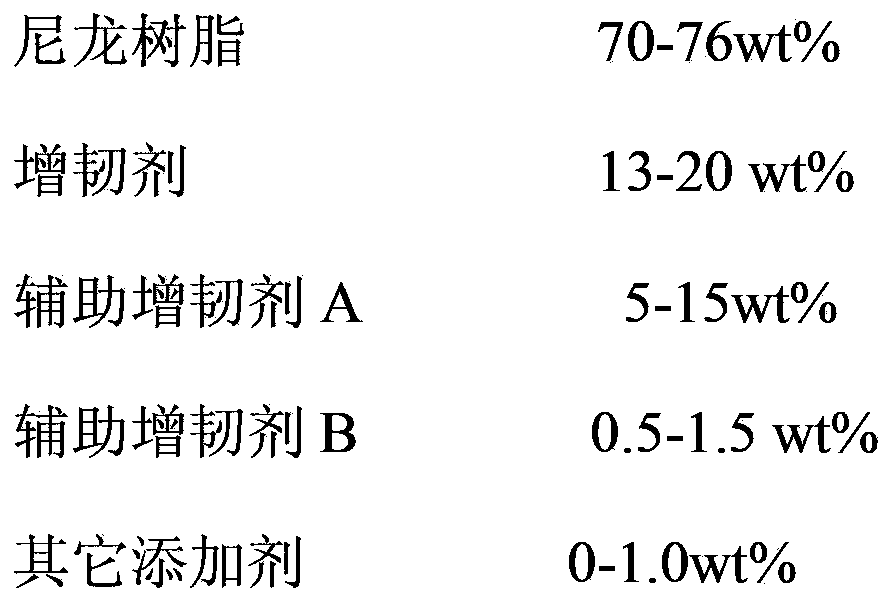

Method used

Image

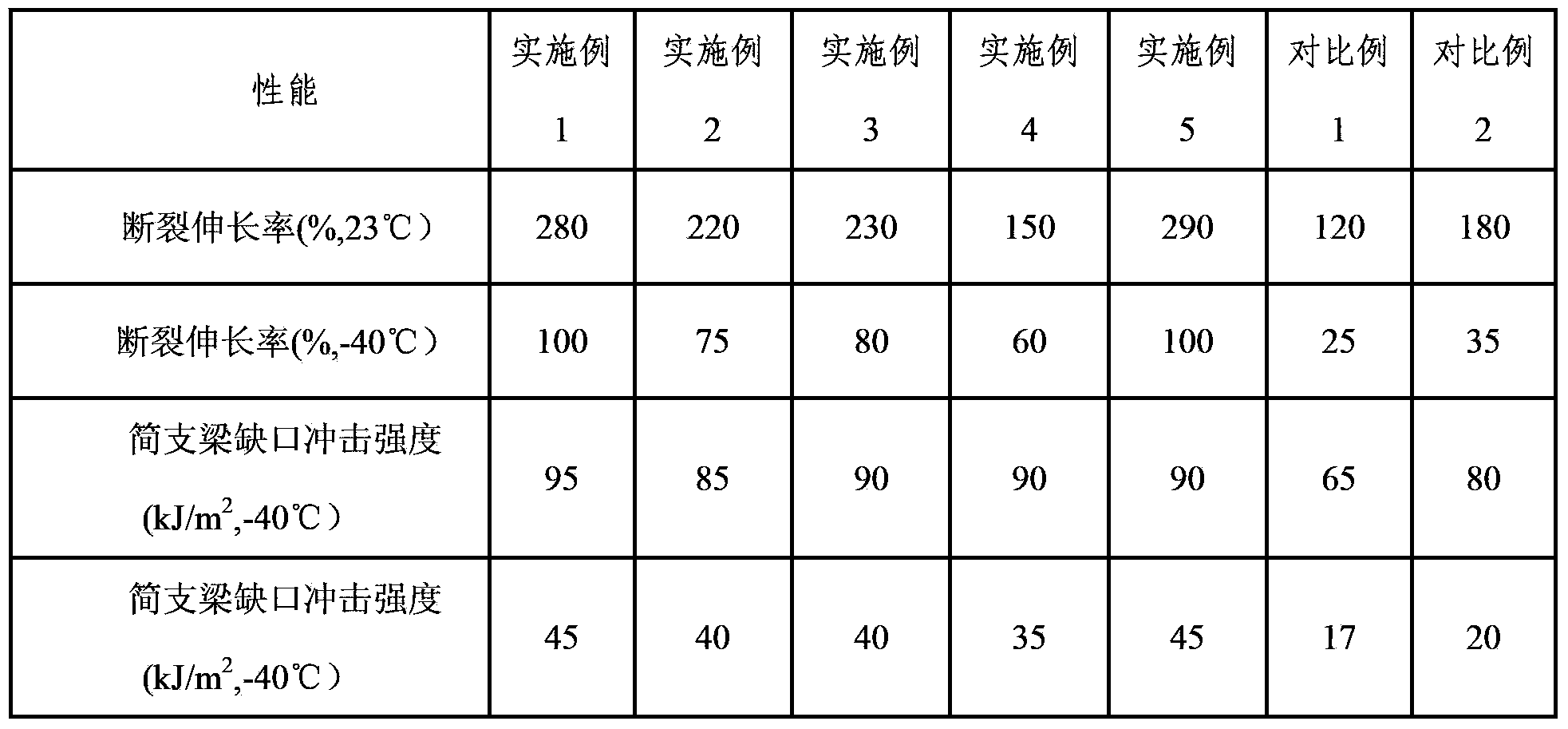

Examples

Embodiment 1

[0019] The low temperature resistant and toughened nylon material of this embodiment has the following composition and weight percentages of each composition: 70wt% of nylon 66 resin, 13wt% of maleic anhydride grafted polyolefin elastomer, 15wt% of polyamide elasticity, 1.5wt% of silicone oil, Antioxidant 0.5wt%.

[0020] The preparation process of the low temperature resistant toughened nylon material is as follows:

[0021] First, add nylon 66 resin, maleic anhydride grafted polyolefin elastomer, polyamide elastomer, silicone oil and antioxidant into the high-speed mixer, stir evenly, and then feed the mixture into the twin-screw extruder from a precision feeder machine, cooling, drying and pelletizing after extrusion.

Embodiment 2

[0023] The low temperature resistant and toughened nylon material of this embodiment has the following composition and weight percentages of each composition: nylon 66 resin 74wt%, maleic anhydride grafted polyolefin elastomer 15wt%, polyamide elastomer 10wt%, silicone oil 0.5wt% , Antioxidant 0.5wt%.

[0024] The preparation process of the low temperature resistant toughened nylon material is as follows:

[0025] First, add nylon 66 resin, maleic anhydride grafted polyolefin elastomer, polyamide elastomer, silicone oil and antioxidant into the high-speed mixer, stir evenly, and then feed the mixture into the twin-screw extruder from a precision feeder machine, cooling, drying and pelletizing after extrusion.

Embodiment 3

[0027] The low temperature resistant and toughened nylon material of this embodiment has the following composition and weight percentages of each composition: nylon 66 resin 74wt%, maleic anhydride grafted polyolefin elastomer EPDM rubber 15wt%, polyamide elastomer 10wt% , 0.5wt% silicone oil, 0.5wt% antioxidant.

[0028] The preparation process of the low temperature resistant toughened nylon material is as follows:

[0029] First, add nylon 66 resin, maleic anhydride grafted EPDM rubber, polyamide elastomer, silicone oil and antioxidant into the high-speed mixer, stir evenly, and then feed the mixture into the twin-screw extruder from a precision feeder. Extruded from the machine, cooled, dried and pelletized after extrusion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com