Soil conditioner and preparation method thereof

A soil conditioner and roasting technology, applied in the soil field, can solve the problems of not finding a suitable utilization method, unfavorable large-scale application and promotion, and difficulty in obtaining raw materials, so as to improve stress resistance and resistance to diseases and insect pests, and reduce soil structure. the deterioration of the effect of improving the effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

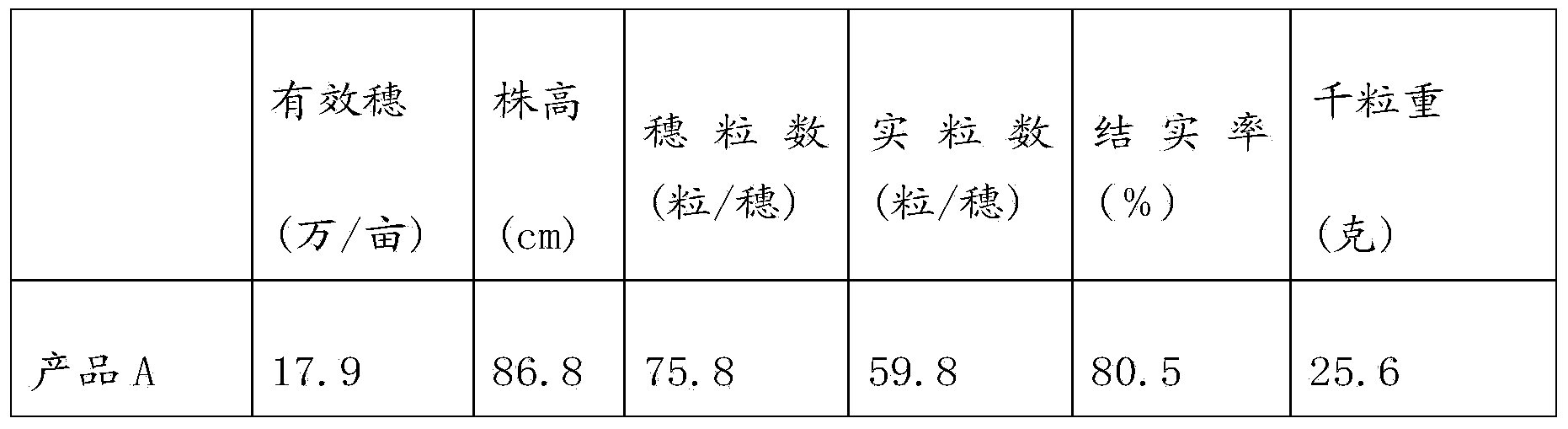

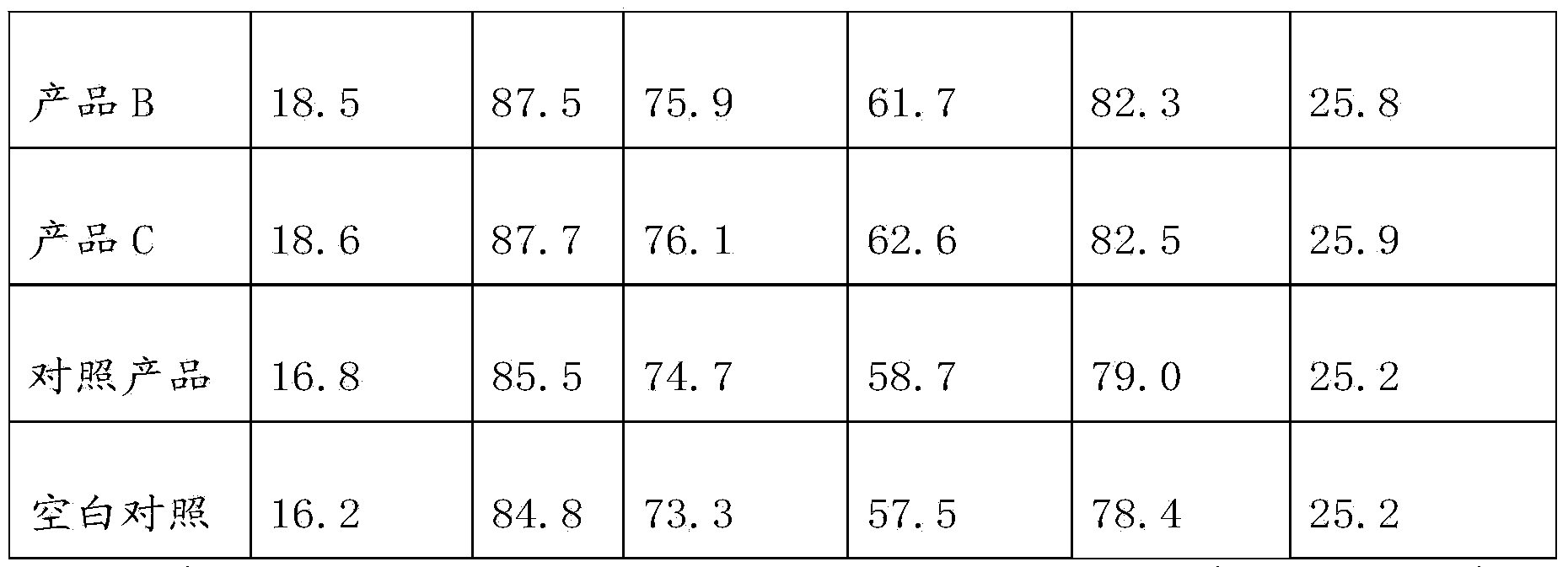

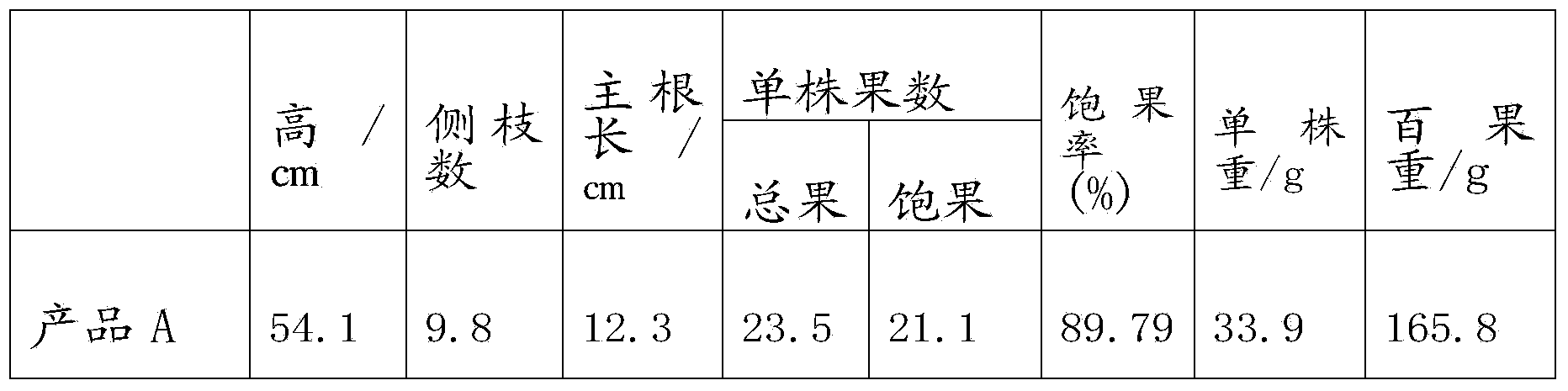

Embodiment 1

[0022] A soil conditioner. In this embodiment, oyster shells, such as marine biological shells, are preferably used as raw materials. First, the oyster shells are collected and screened. After cleaning, the gas generator is started, and coal is put into the gas generator to generate gas, which is introduced through pipelines. In the drying rotary kiln, when the gas in the rotary kiln reaches the ignitable solubility, the ignition is started, and the temperature in the rotary kiln reaches 800°C; at the same time, the oyster shells are put into the feeding port at the top of the rotary kiln through the conveyor belt, and then enter the drying and roasting process. After 13 minutes, it is exported from the rotary kiln through the conveyor belt; it is naturally cooled by the 30-meter conveyor belt, and then cooled by the wind blowing on the 30-meter conveyor belt (the whole cooling process is 5 minutes), and then enters the ball mill for grinding. After being exported through a 100...

Embodiment 2

[0024] A kind of soil conditioner, the roasting temperature that adopts during preparation is 1000 ℃, and roasting time is 5 minutes, all the other methods are identical with embodiment 1, the sieve residue after passing through 100 mesh sieves is 6%, the product CaO=46 of gained % (mass percentage), pH=9.6, the obtained product is "product B".

Embodiment 3

[0026] A kind of soil conditioner, the roasting temperature that adopts during preparation is 1200 ℃, and roasting time is 30 minutes, all the other methods are identical with embodiment 1, the sieve residue after crossing 100 mesh sieves is 5%, the product CaO=52 of gained % (mass percentage), pH=10.8, the resulting product is "Product C"

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com