Strain capable of massively yielding glucose-6-acetic ester and method for synthesizing glucose-6-acetic ester

A technology of glucose and microbial strains, applied in the field of biochemical engineering, can solve the problems of long fermentation time, poor passage stability, and unsuitable for industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

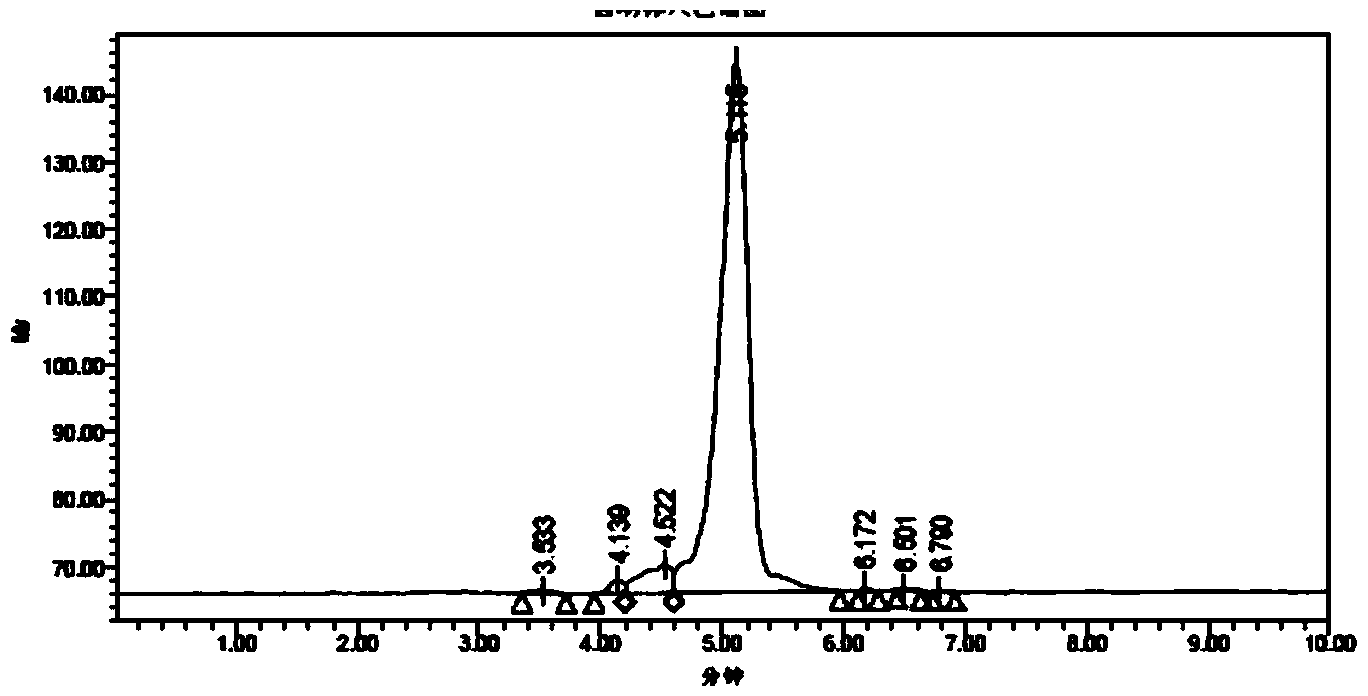

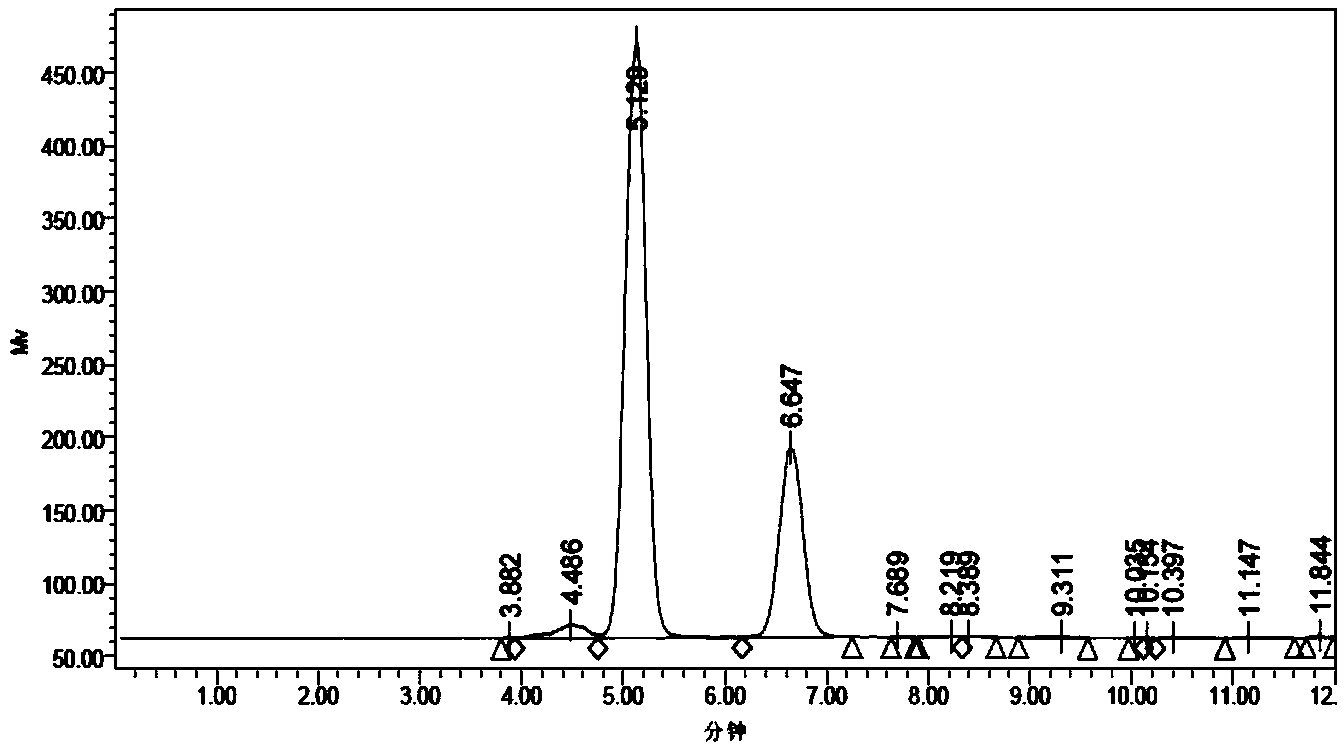

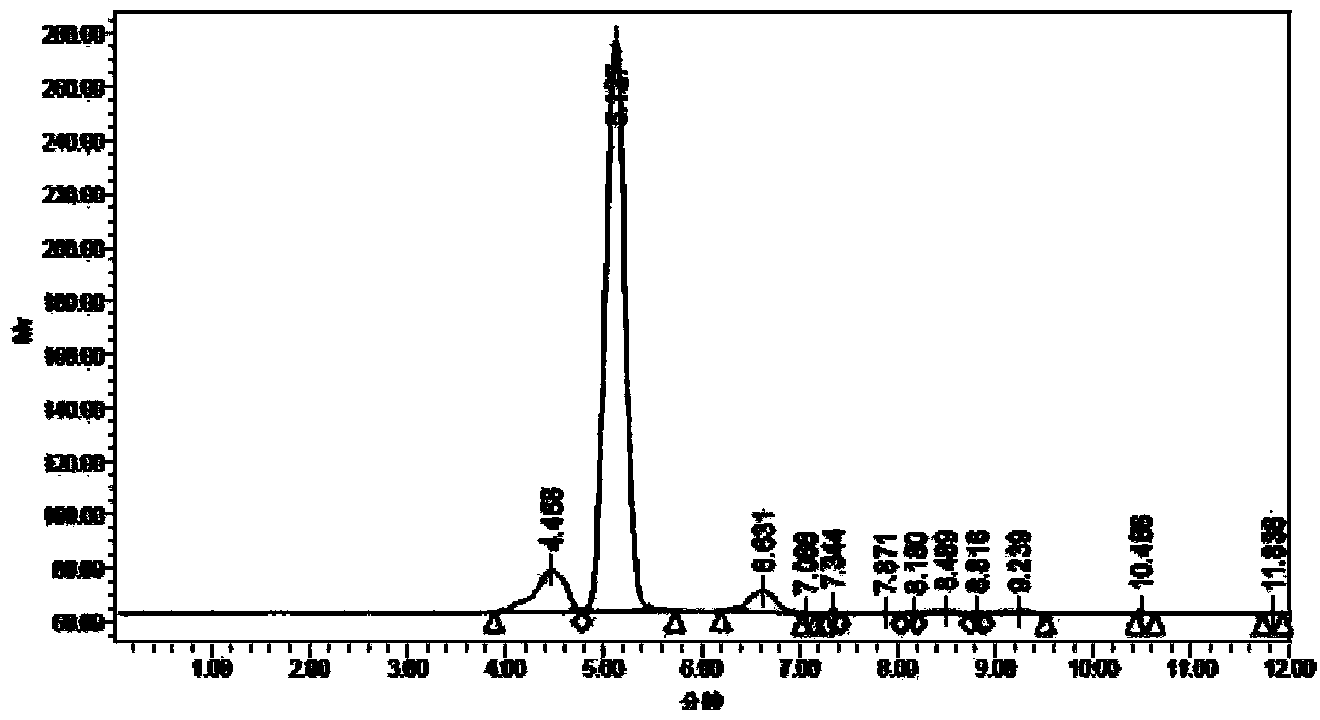

Image

Examples

Embodiment 1

[0056] The steps of the fermentation separation method for producing glucose-6-acetate are as follows:

[0057] (1) Inclined cultivation of strains

[0058] Inoculating the Bacillus sp. strain GXU-011 strain into the slant medium in the test tube to make the slant strain;

[0059] Among them, the slant culture medium of bacterial species is composed of the following parts by weight:

[0060] 40g sucrose, 2g yeast powder, KH 2 PO 4 0.5g, K 2 HPO 4 0.5g, MgSO 4 0.5g, 15g agar powder and 1000 parts of water;

[0061] The technological conditions for preparing the slant strains were pH 6.5, temperature 28°C, and culture time 24 hours.

[0062] (2) Inoculation and fermentation

[0063] Expand the cultivation of slant strains into seed liquid;

[0064] Connect the seed liquid to the fermentor at 5% of the inoculum for fermentation;

[0065] The seed liquid and fermentation liquid are composed of the following parts by weight:

[0066] 40 parts glucose, 5 parts peptone, 5 parts yeast powder, 1 part...

Embodiment 2

[0076] The steps of the fermentation separation method for producing glucose-6-acetate are as follows:

[0077] (1) Inclined cultivation of strains

[0078] Inoculating the Bacillus sp. strain GXU-011 strain into the slant medium in the test tube to make the slant strain;

[0079] Among them, the slant culture medium of bacterial species is composed of the following parts by weight:

[0080] Cane sugar 50g, yeast powder 6g, KH 2 PO 4 2g, K 2 HPO 4 2g, MgSO 4 2g, 20g agar powder and 1000 parts of water;

[0081] The technological conditions for preparing the slant strains were pH 7.0, temperature 30°C, and culture time 30 hours.

[0082] (2) Inoculation and fermentation

[0083] Expand the cultivation of slant strains into seed liquid;

[0084] Connect the seed liquid to the fermenter at 8% of the inoculum for fermentation;

[0085] The seed liquid and fermentation liquid are composed of the following parts by weight:

[0086] 50 parts of glucose, 8 parts of peptone, 8 parts of yeast powder, ...

Embodiment 3

[0093] The steps of the fermentation separation method for producing glucose-6-acetate are as follows:

[0094] (1) Inclined cultivation of strains

[0095] Inoculating the Bacillus sp. strain GXU-011 into the slant medium in the test tube to make the slant strain;

[0096] Among them, the slant culture medium of bacterial species is composed of the following parts by weight:

[0097] 60g sucrose, 8g yeast powder, KH 2 PO 4 1.5g, K 2 HPO 4 1.5g, MgSO 4 1.5g, 25g agar powder and 1000 parts of water;

[0098] The process conditions for preparing the slant strains were pH 7.5, temperature 32°C, and culture time 36 hours.

[0099] (2) Inoculation and fermentation

[0100] Expand the cultivation of slant strains into seed liquid;

[0101] Connect the seed liquid to the fermenter at 10% of the inoculum for fermentation;

[0102] The seed liquid and fermentation liquid are composed of the following parts by weight:

[0103] 60 parts glucose, 8 parts peptone, 9 parts yeast powder, 2 parts potassium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com