Production system of burying matter for pet feces

A production system and excrement technology, applied in animal houses, applications, animal husbandry, etc., can solve the problems of low granulation efficiency, high granule water content, low granulation yield, etc., and achieve fast drying speed and high product quality. High quality, good product quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

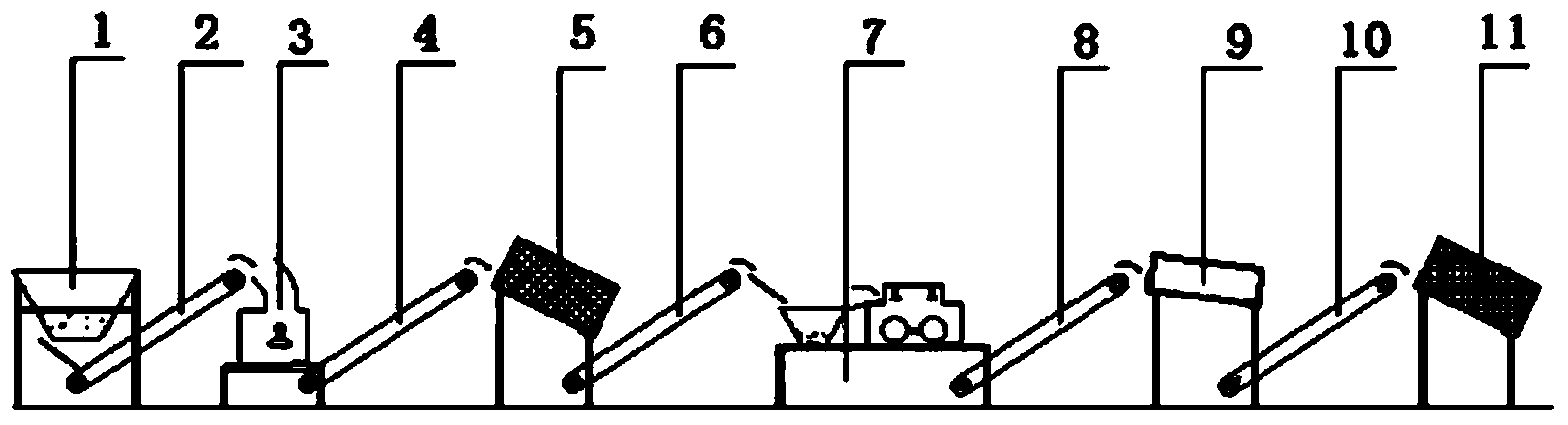

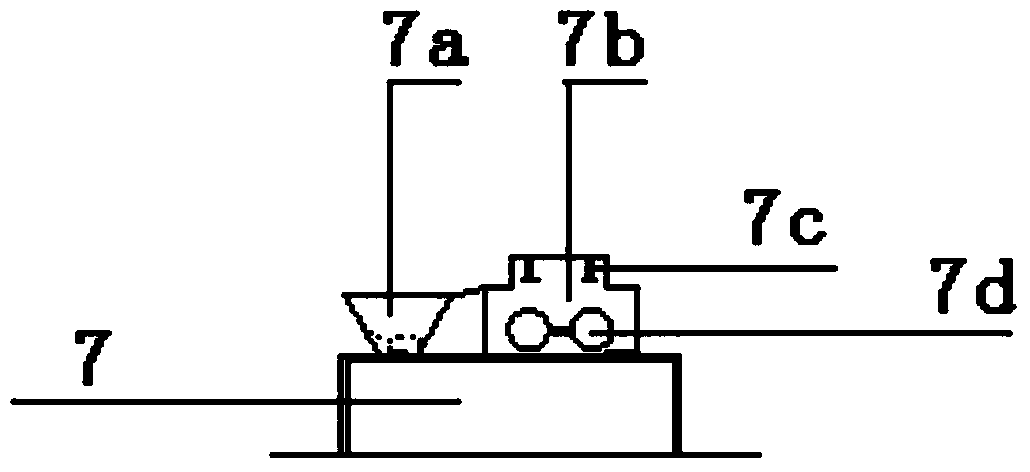

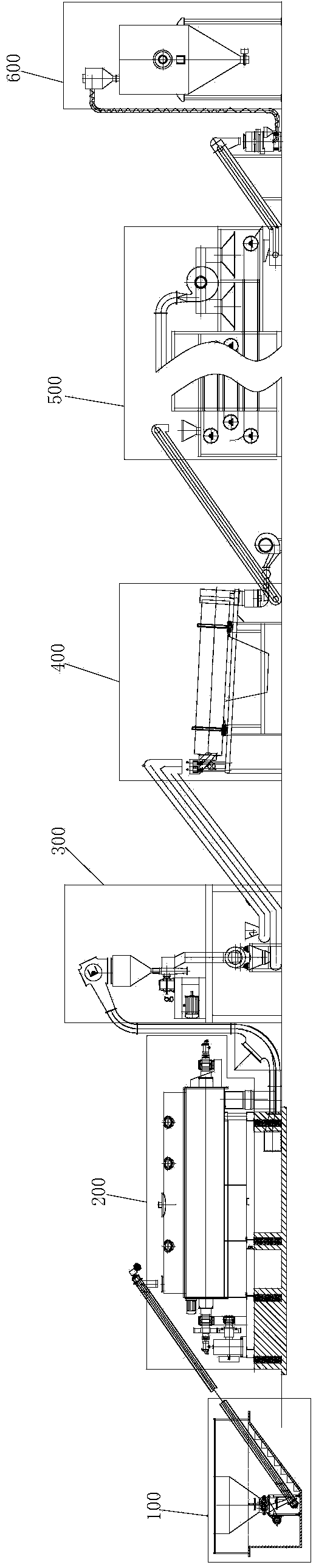

[0044] refer to image 3, the production system of the landfill of pet excrement of the present invention comprises crusher 100, paddle drier 200, granulator 300, coating machine 400, drier 500, vibrating screen 600 and screening machine 700, and working process is : After the primary crushing and secondary crushing are carried out to the material by the crusher 100, the material output from the crusher is transported to the paddle dryer 200 through the first conveyor (screw conveyor), and after being dried by the paddle dryer 200 , the material output from the paddle dryer 200 is transported to the granulator 300 through the second conveyor (scraper conveyor, or bucket elevator, or screw conveyor), and the material is granulated by the granulator , the granular matter (that is, landfill) output from the granulator 300 is transported...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com