Method and device for treating and recycling organic exhaust gas with low concentration and large air volume

A technology for organic waste gas and recovery methods, applied in separation methods, chemical instruments and methods, and separation of dispersed particles, which can solve the problems of limited air volume, low concentration, high investment, etc., achieve efficient adsorption treatment and recovery, and have a reasonable device structure , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

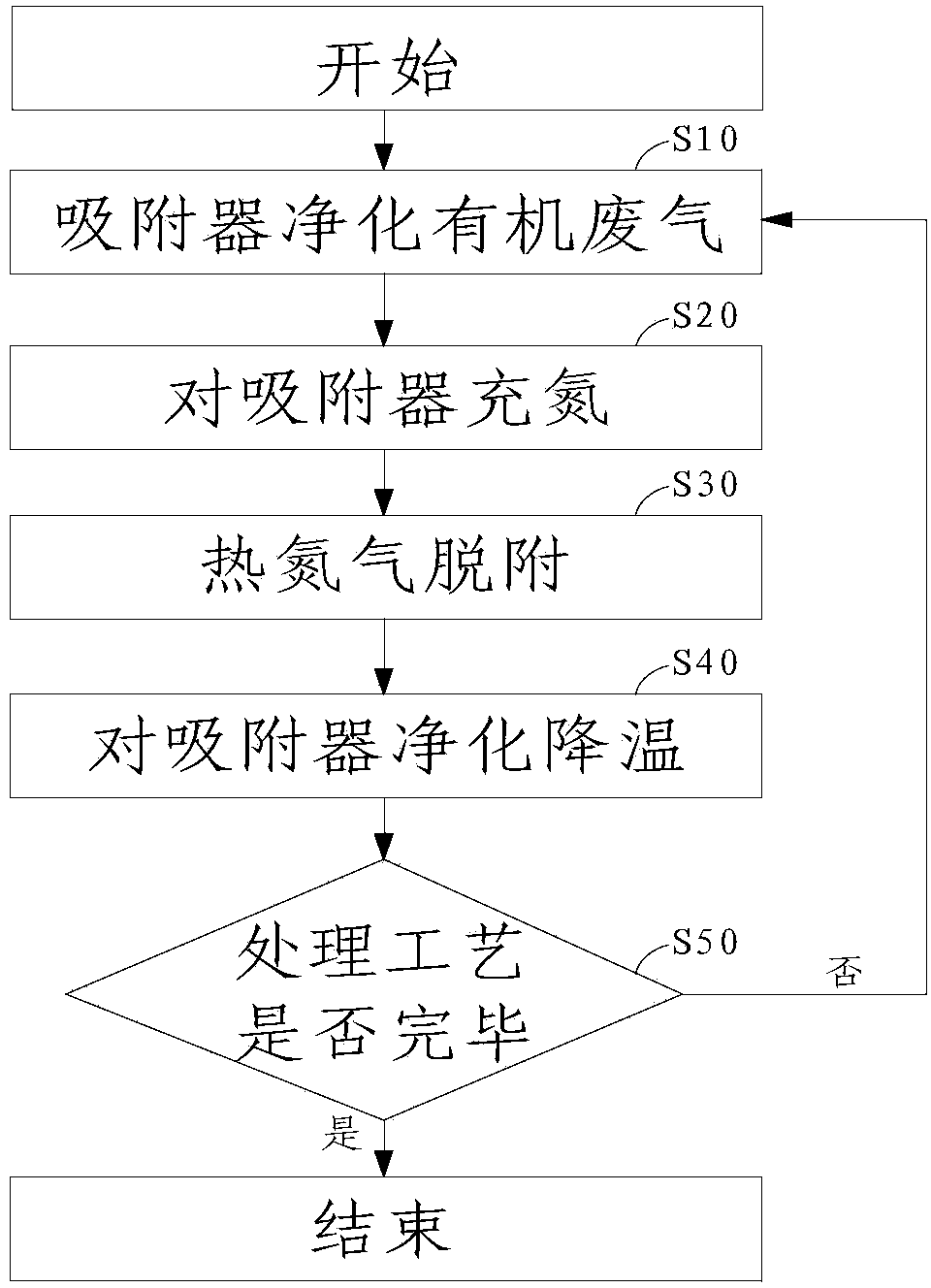

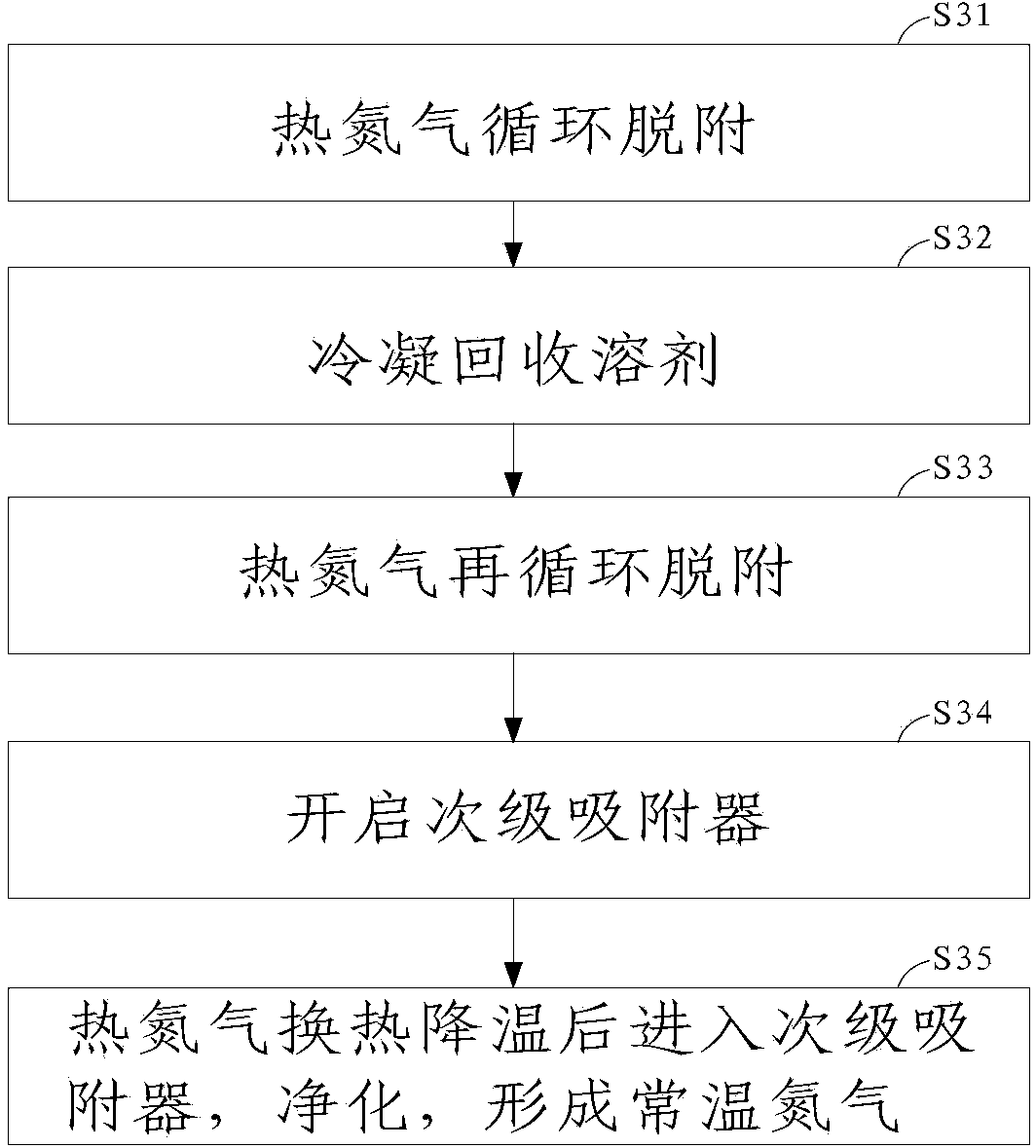

Method used

Image

Examples

Embodiment 1

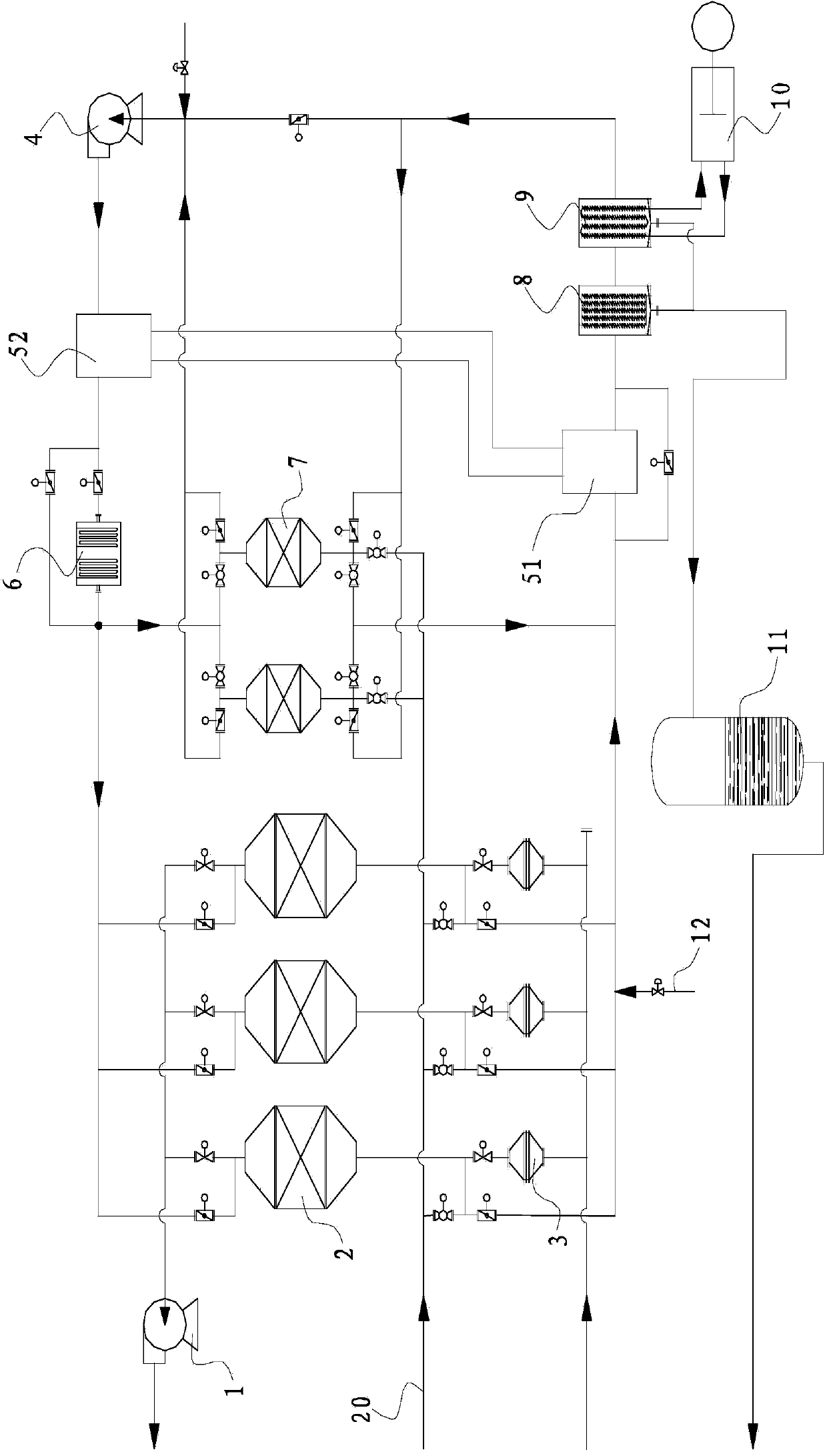

[0041] Such as image 3 As shown, this preferred embodiment provides a low-concentration and high-volume organic waste gas treatment and recovery device, which includes an adsorption system and a desorption system. The adsorption system includes three pretreatment devices 3 , three honeycomb activated carbon adsorbers 2 , and an exhaust fan 1 . Each pretreatment device 3 corresponds to an independent honeycomb activated carbon adsorber 2 (all adsorbers 2 can also share a set of pretreatment device 3), and the air inlet and outlet of the honeycomb activated carbon adsorber 2 are equipped with airtight valves.

[0042] The desorption system includes a nitrogen generator 20, a first end of a heat exchanger 51, a surface cooler 8, a condensation unit, a circulating fan 4, a second end of a heat exchanger 52, and a heater 6 connected in sequence through pipelines, and two A secondary adsorber 7. One end of the secondary adsorber 7 is connected to the gas outlet of the nitrogen ge...

Embodiment 2

[0057] The device used in this preferred embodiment includes an adsorption system and a desorption system. The adsorption system uses honeycomb activated carbon as the adsorbent, and the desorption system uses hot nitrogen as the desorption gas.

[0058] Workflow: Use honeycomb activated carbon as the adsorbent to adsorb the solvent in the organic waste gas, and use hot nitrogen to desorb the adsorbent when the solvent in the adsorbent reaches the set saturation value. The hot nitrogen continues to circulate after desorbing the adsorbent; when the solvent contained in the hot nitrogen reaches the condensed state at room temperature, the solvent in the hot nitrogen is condensed and recovered.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com