Device and method for preventing ammonia recovery film assembly from being blocked in MOCVD (Metal Organic Chemical Vapor Deposition) production of gallium nitride

A technology of membrane components and gallium nitride, which is applied in the field of ammonia gas treatment, can solve problems such as easy clogging, and achieve the effects of avoiding clogging and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

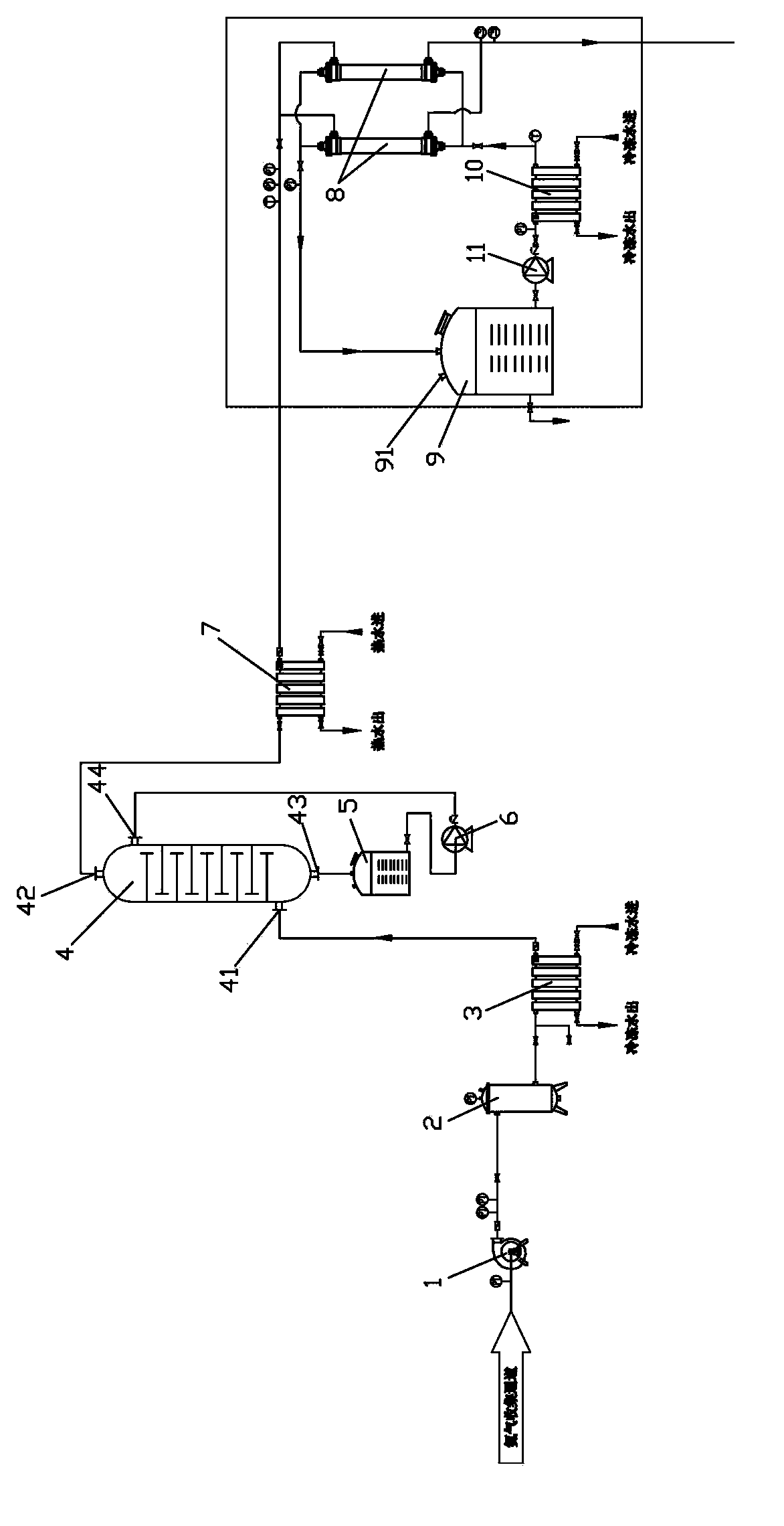

[0027] refer to figure 1 A device for preventing the clogging of the ammonia gas recovery membrane module for producing gallium nitride by MOCVD, including a front assembly connected to the ammonia collection pipeline, a pretreatment assembly and a first-stage ammonia absorption assembly, and the front assembly includes blowers 1, Filtration device 2, heat exchanger 3 3. The pretreatment component includes a plate tower 4, an alkaline water tank 5, a circulation pump 2 6 and a heat exchanger 2 7, and the plate tower 4 includes a mixed gas inlet 41, a mixed gas outlet 42, an alkaline water inlet 43 and an alkaline water outlet 44 , the alkaline water inlet 43, the alkaline water tank 5, the circulation pump two 6 and the alkaline water outlet 44 are connected sequentially, the mixed gas inlet 41 is connected with the outlet of the heat exchanger three 3, the mixed gas outlet is connected with the heat exchanger two 7 The inlet is connected, hot water enters at one end of the l...

Embodiment 2

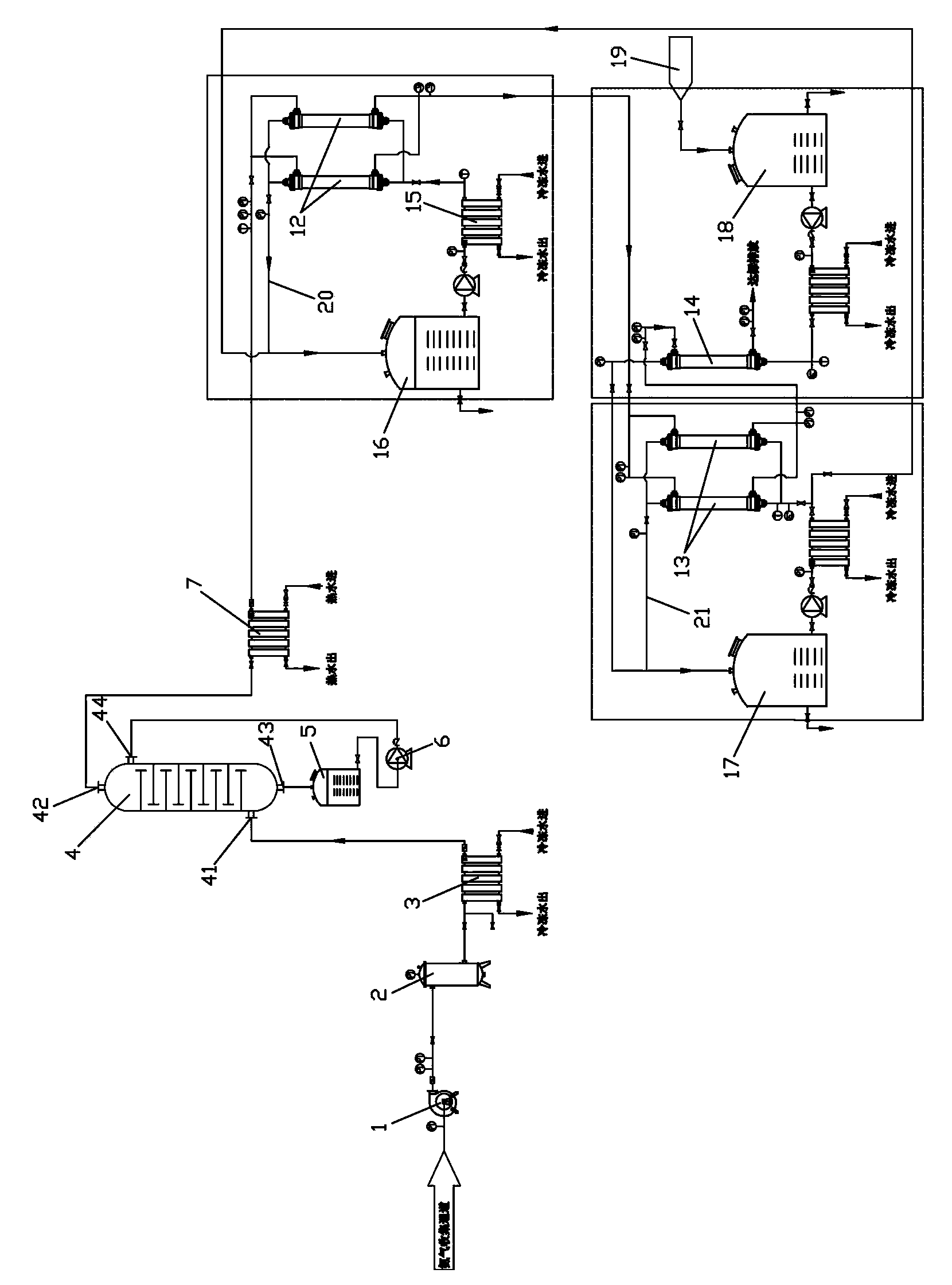

[0029] refer to figure 2 , The main difference between this embodiment and Embodiment 1 is that this embodiment uses a three-stage ammonia gas absorption component. The membrane elements in the first-stage ammonia absorption assembly and the second-stage ammonia absorption assembly in the three-stage ammonia absorption assembly are composed of two sets of membrane elements connected in parallel, and the ammonia absorption assembly at each stage includes a membrane assembly and an ammonia water storage tank 1, heat exchanger 1, circulation pump 1, the membrane module includes an air inlet, an air outlet, a water outlet, a water inlet, an ammonia storage tank, a circulation pump 1, and heat exchanger 1, and the water inlet is connected in sequence, and the first-stage membrane module 12 The air inlet of the first-stage membrane module 12 is connected to the heat exchanger 15, the air outlet of the first-stage membrane module 12 is connected in series with the air inlet of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com