Dielectrophoresis hollow fiber membrane assembly

A technology of dielectrophoresis and fiber membranes, applied in the field of separation, can solve problems such as unsuitable industrial conditions, obstacles to widespread use, and pH value changes, and achieve the effects of increasing membrane permeation, increasing service life, and reducing energy and costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following describes the present invention in further detail through the accompanying drawings and specific embodiments, but the present invention is not limited to the following embodiments. Any changes or alternatives made in the principle of this embodiment fall into the scope of the present invention. Among.

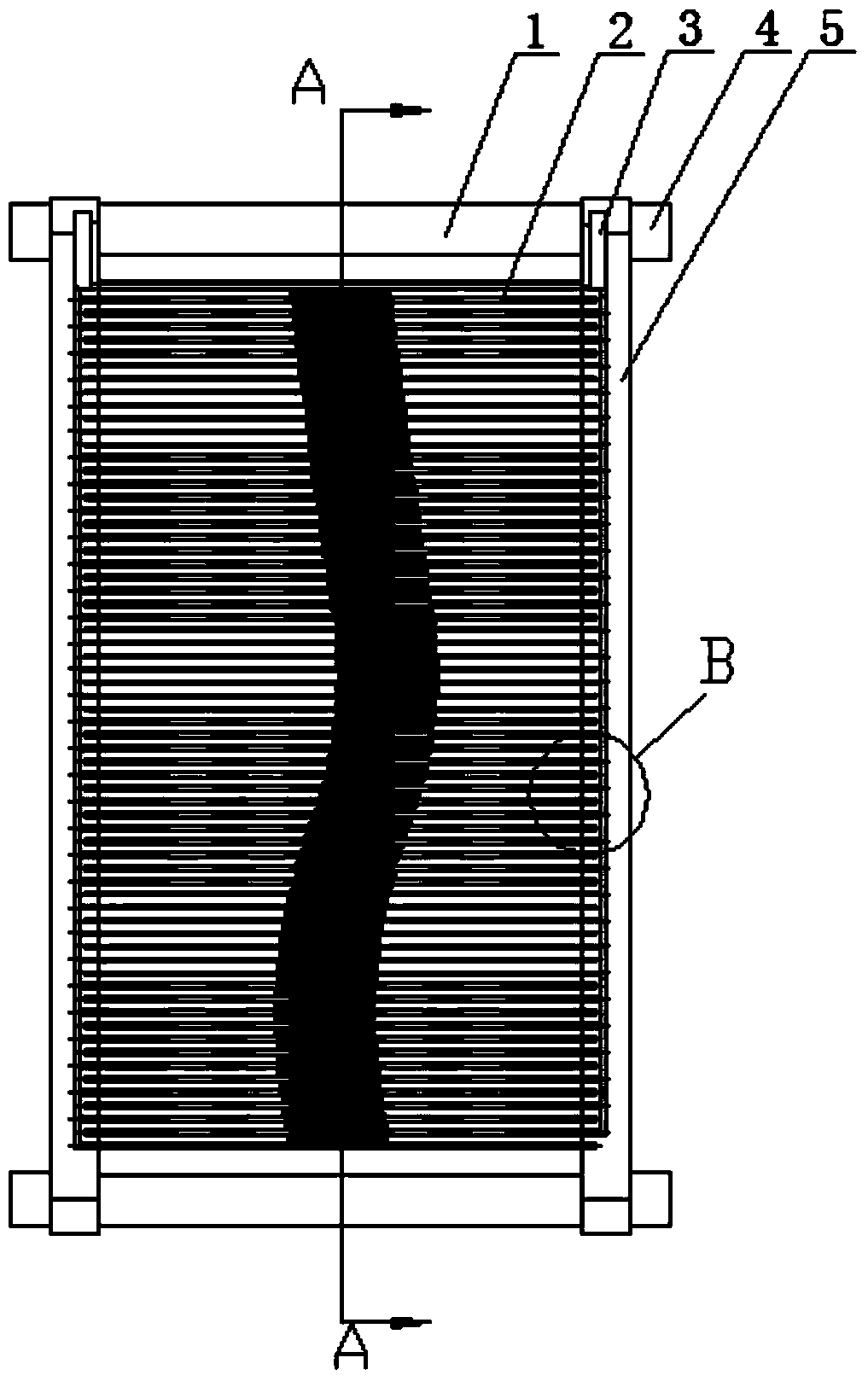

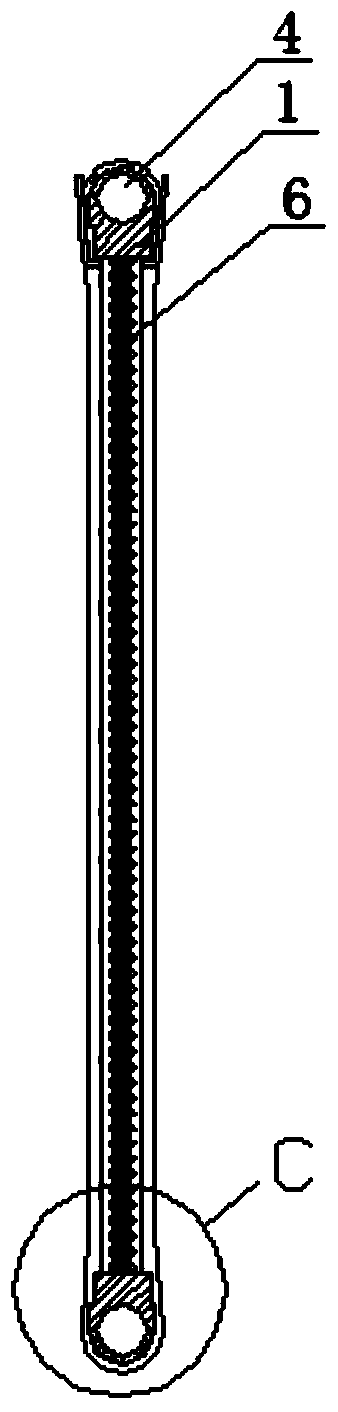

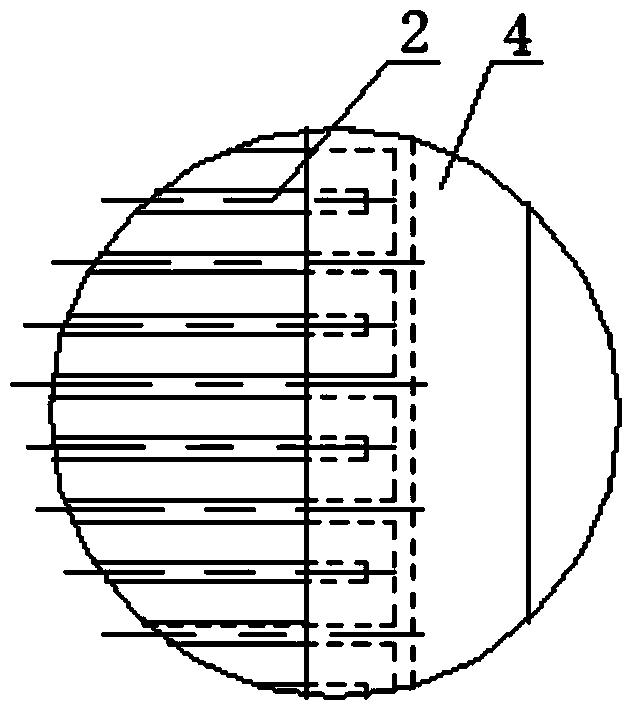

[0023] A hollow fiber membrane module for dielectrophoresis, such as figure 1 , 2 As shown, it includes the main frame 1, the electrode mounting plate 5, and the hollow fiber membrane 6. It is a frame-curtain structure. The main frame and the electrode mounting plate form a frame-curtain structure. The main frame is set up and down, and the electrode mounting plate is on the left, Set on the right, the main frame and the electrode mounting plate are made of ABS and formed by compression molding. The hollow fiber membrane is installed vertically between the frame composed of the main frame and the electrode mounting plate, and the frame on the front and back of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com