Automatic screw rod cleaning device

A self-cleaning, screw technology, applied in cleaning methods and utensils, cleaning methods using tools, chemical instruments and methods, etc., can solve the problems of plastic shovel knocking difficulties, increased work intensity, high cost, etc., to avoid hardness reduction, reduce High labor intensity and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

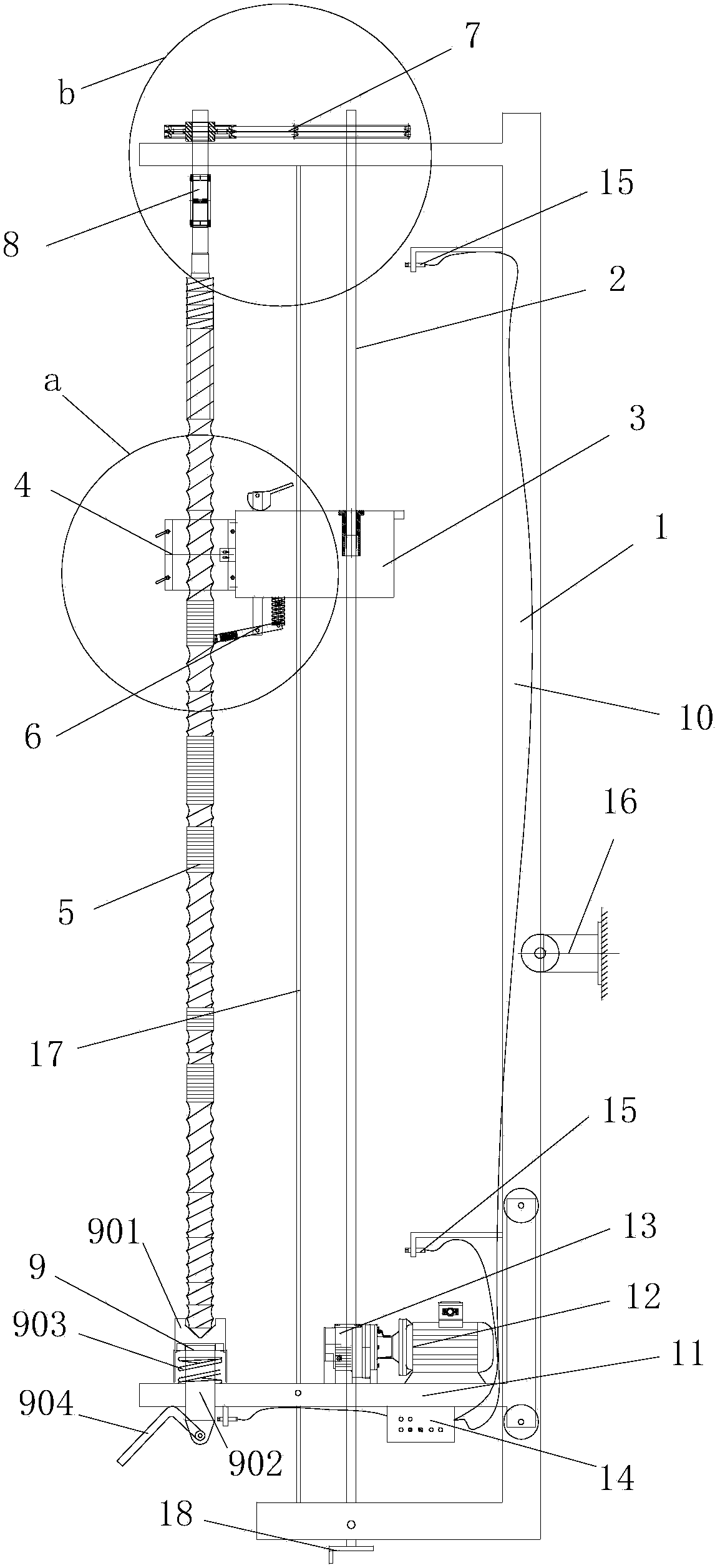

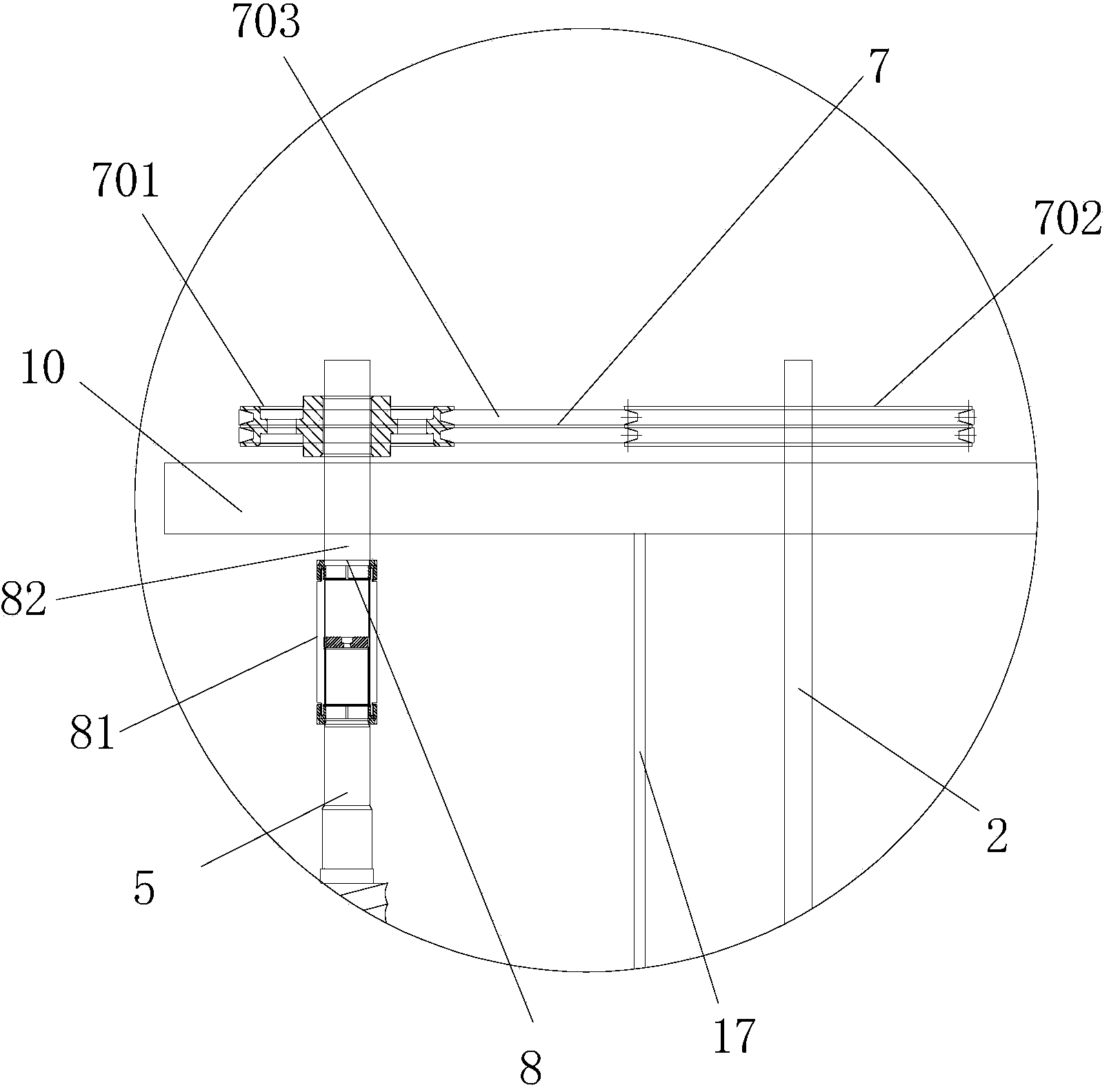

[0030] Such as Figure 1 to Figure 3 A kind of screw automatic cleaning device shown, comprises the cleaning rack 1 that is used for clamping screw rod 5, screw mandrel 2, mobile workbench 3 and heating ring 4, and the two ends of described screw mandrel 2 are installed on the two ends of cleaning rack 1 One end of the mobile worktable 3 is installed on the screw rod 2, and the heating ring 4 is fixed on the other end of the mobile workbench 3; Pass. Specifically, such as Figure 4 and Figure 5 As shown, the heating ring 4 is preferably an infrared heating ring. The heating ring 4 is mainly composed of two main bodies with a semicircular cross-section, one end of the two main bodies is connected together by a bolt 19, and the other end is fixed on the other end of the mobile workbench.

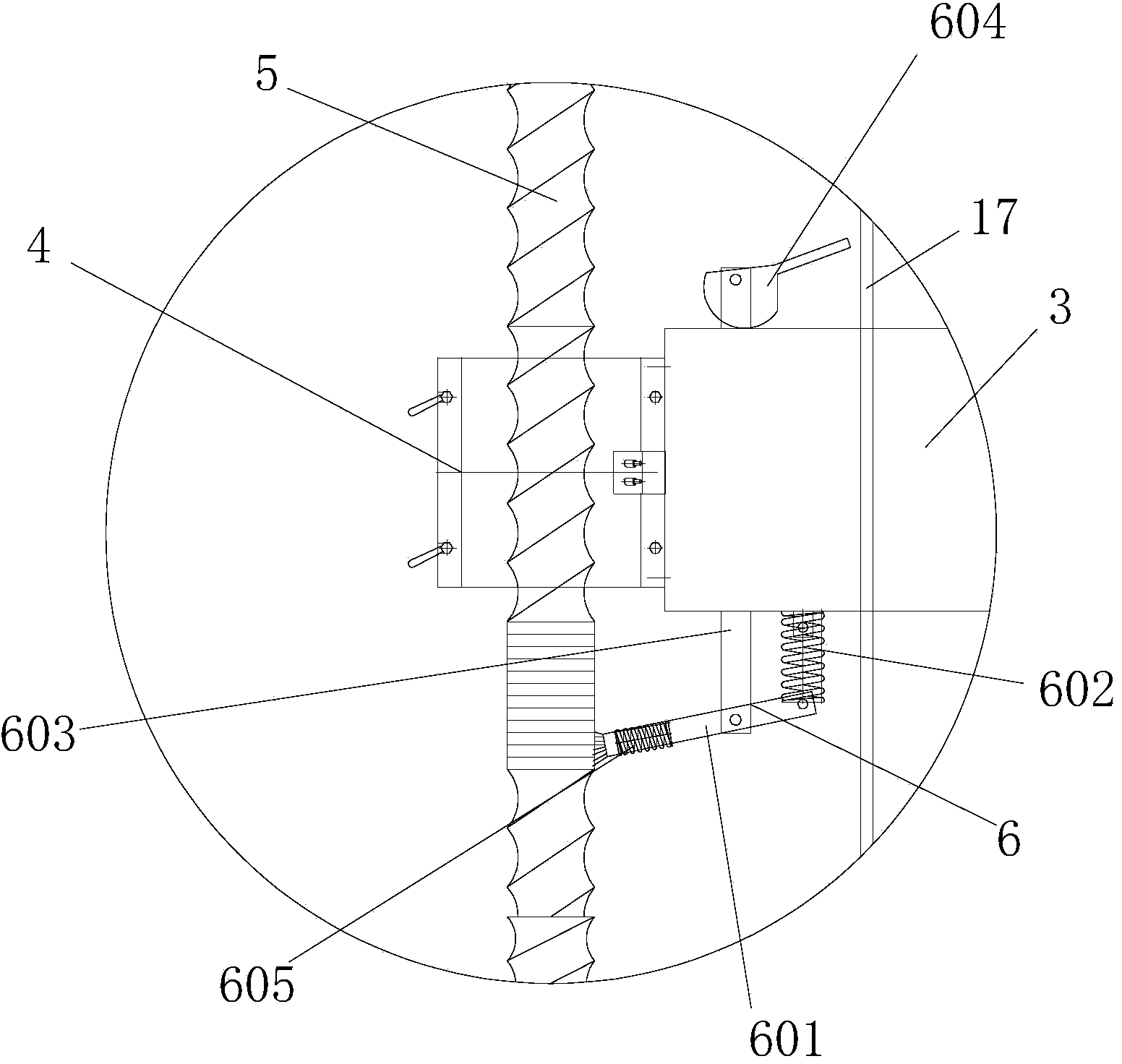

[0031]In order to further improve the cleaning effect, such as figure 2 As shown, the other end of the mobile workbench 3 is provided with a scrubbing mechanism 6, and the scrubbing mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com