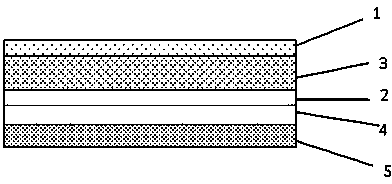

Window film adhered onto outer side of window glass

A technology for window glass and window film, applied in synthetic resin layered products, layered products, chemical instruments and methods, etc., can solve problems such as short use time and embrittlement, reduce damage, ensure aging resistance, guarantee The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

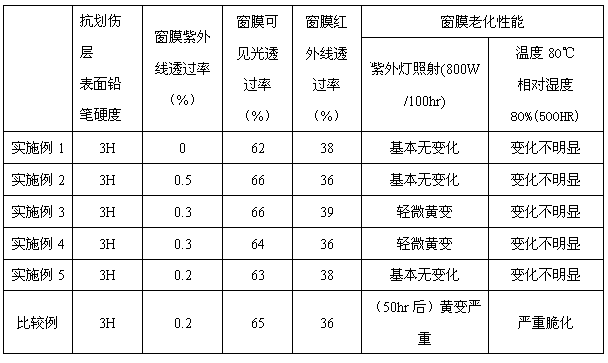

Examples

Embodiment 1

[0035] Preparation of anti-scratch and weather-resistant layer coating solution:

[0036] Multifunctional urethane acrylate prepolymer (EBECRYL294 / 25HD) 30 parts by weight

[0037] Fluorinated glycol diacrylate 10 parts by weight

[0038] 14 parts by weight of 2-fluoroacrylate

[0039] Photoinitiator (184) 3 parts by weight

[0040] 40 parts by weight of ethyl acetate

[0041] BYK-307 1 part by weight

[0042] 2,4,6-tris(2'-butoxyphenyl)-1,3,5-triazine 2 parts by weight

[0043] Add the above-mentioned substances into a container, and stir evenly to obtain a coating solution for an anti-scratch and weather-resistant layer.

[0044] The parts by weight in each embodiment of the present invention may be g or kg.

[0045] Preparation of window film:

[0046] Gravure coating heat insulation layer on one side of polyester film (PET film), wet coating weight 15g / m 2 , cured by ultraviolet light after drying to obtain a heat-insulating layer with a dry film thickness of a...

Embodiment 2

[0048] Preparation of anti-scratch and weather-resistant layer coating solution:

[0049] Multifunctional urethane acrylate prepolymer (BASF LR-8987 prepolymer) 20 parts by weight

[0050] 30 parts by weight of fluorine-containing polyurethane acrylate

[0051] 25 parts by weight of 2-fluoroacrylate

[0052] 1173 4 parts by weight

[0053] 40 parts by weight of ethyl acetate

[0054] BYK-307 0.5 parts by weight

[0055] 2,4,6-tris(2'-butoxyphenyl)-1,3,5-triazine 0.5 parts by weight

[0056] Add the above-mentioned substances into a container, and stir evenly to obtain a coating solution for an anti-scratch and weather-resistant layer.

[0057] Preparation of window film:

[0058] Gravure coating heat insulation layer on one side of polyester film (PET film), wet coating weight 15g / m 2 , UV curing after drying to obtain a heat insulation layer with a dry film thickness of about 10um; apply the above-mentioned anti-scratch and weather-resistant layer coating liquid on the h...

Embodiment 3

[0060] Preparation of anti-scratch and weather-resistant layer coating solution:

[0061] Pure acrylate prepolymer (6530B-40 from Changxing Company, etc.) prepolymer 60 parts by weight

[0062] 5 parts by weight of fluorine-containing polyurethane acrylate

[0063] TPO 3 parts by weight

[0064] 30 parts by weight of butyl acetate

[0065] BYK-306 1 part by weight

[0066] 1 part by weight of phenyl o-hydroxybenzoate

[0067] Add the above-mentioned substances into a container, and stir evenly to obtain a coating solution for an anti-scratch and weather-resistant layer.

[0068] Preparation of window film:

[0069] Gravure coating heat insulation layer on one side of polyester film (PET film), wet coating weight 15g / m 2 , cured by ultraviolet light after drying to obtain a heat-insulating layer with a dry film thickness of about 10um; coat the above-mentioned anti-scratch and weather-resistant layer coating liquid on the heat-insulating layer, and the wet coating amount ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com