Lightweight insulation spray paint for circulating fluidized bed boiler, and production and construction technology thereof

A circulating fluidized bed, lightweight thermal insulation technology, applied in the field of refractory materials, can solve the problems of long construction period and many labor, and achieve the advantages of shortened construction period, reduced construction cost, good thermal shock resistance and thermal insulation performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

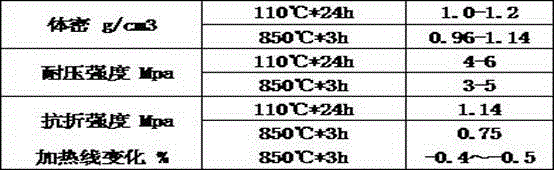

Image

Examples

Embodiment 1

[0046] The invention provides a light-weight heat-insulating spray coating for a circulating fluidized bed boiler. The components contained and the parts by mass are as follows:

[0047] 20 parts of waste light insulation brick particles;

[0048] 15 parts of light raw material A;

[0049] Clay B20 parts;

[0050] 20 parts of curing agent C;

[0051] 3 parts perlite.

[0052] The particle size of the waste lightweight thermal insulation bricks is 1-3mm, and the refractoriness is 1670°C.

[0053] The light raw material A component is a by-product of the power plant: floating beads, particle size 0.1-0.3mm, Al 2 o 3 Content 30-37%, bulk density 0.13g / cm 3 .

[0054] Clay B is heat-resistant clay with a particle size of ≤150 mesh, a refractoriness of 1690°C, Al 2 o 3 The content is 33%.

[0055] Its each component and mass ratio thereof of described curing agent C are:

[0056] 10 parts of A600 high alumina cement;

[0057] 1 part sodium tripolyphosphate;

[0058] Am...

Embodiment 2

[0085] The invention provides a light-weight heat-insulating spray coating for a circulating fluidized bed boiler. The components contained and the parts by mass are as follows:

[0086] 30 parts of waste lightweight thermal insulation brick particles;

[0087] 25 parts of light raw material A;

[0088] Clay B25 parts;

[0089] 27 parts of curing agent C;

[0090] 8 parts perlite.

[0091] The particle size of the waste lightweight thermal insulation bricks is 1-3mm, and the refractoriness is 1670°C.

[0092] The light raw material A component is a by-product of the power plant: floating beads, particle size 0.1-0.3mm, Al 2 o 3 Content 30-37%, bulk density 0.13g / cm 3 .

[0093] Clay B is heat-resistant clay with a particle size of ≤150 mesh, a refractoriness of 1690°C, Al 2 o 3 The content is 33%.

[0094] Its each component and mass ratio thereof of described curing agent C are:

[0095] 10 parts of A600 high alumina cement;

[0096] 1 part sodium tripolyphosphate...

Embodiment 3

[0111] The invention provides a light-weight heat-insulating spray coating for a circulating fluidized bed boiler. The components contained and the parts by mass are as follows:

[0112] 22 parts of waste light heat insulation brick particles;

[0113] 17 parts of light raw material A;

[0114] Clay B22 parts;

[0115] 26 parts of curing agent C;

[0116] 6 parts perlite.

[0117] The particle size of the waste lightweight thermal insulation bricks is 1-3mm, and the refractoriness is 1670°C.

[0118] The light raw material A component is a by-product of the power plant: floating beads, particle size 0.1-0.3mm, Al 2 o 3 Content 30-37%, bulk density 0.13g / cm 3 .

[0119] Clay B is heat-resistant clay with a particle size of ≤150 mesh, a refractoriness of 1690°C, Al 2 o 3 The content is 33%.

[0120] Its each component and mass ratio thereof of described curing agent C are:

[0121] 10 parts of A600 high alumina cement;

[0122] 1 part sodium tripolyphosphate;

[012...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com