Method for preparing artemisinic acid

A technology of artemisinic acid and Artemisia annua, applied in the biological field, can solve the problems of unsuitability for industrialized production, low extraction efficiency, complicated operation, etc., and achieves the effects of environmental friendliness, high extraction efficiency, and simple method operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

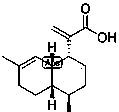

Image

Examples

Embodiment 1

[0016] Take 5kg of dried Artemisia annua raw material, pulverize it to 20 meshes, place it in a CO2 supercritical extraction tank for extraction, pass in liquid CO2, the flow rate is 3ml / min / g raw material, the extraction temperature is 40°C, the pressure is 18Mpa, and the extraction time is 2h. The extract was dissolved with 30 times the volume of 5% sodium bicarbonate solution. After the dissolved solution was filtered, an equal volume of petroleum ether was added and stirred thoroughly. The hydrochloric acid solution was adjusted to pH3. After 20 hours of crystallization, the crystals were recrystallized with anhydrous methanol and dried to obtain 3.2 g of artemisinic acid with a content of 98.6%.

Embodiment 2

[0018] Take 5kg of dried Artemisia annua raw material, pulverize it to 40 meshes, place it in a CO2 supercritical extraction tank for extraction, introduce liquid CO2, the flow rate is 5ml / min / g raw material, the extraction temperature is 45°C, the pressure is 20Mpa, and the extraction time is 1h. The extract was dissolved with 40 times the volume of 10% sodium bicarbonate solution. After the solution was filtered, an equal volume of petroleum ether was added to stir well. The hydrochloric acid solution was adjusted to pH5. After 10 hours of crystallization, the crystals were recrystallized with anhydrous methanol and dried to obtain 4.9 g of artemisinic acid with a content of 97.1%.

Embodiment 3

[0020] Take 5kg of dried Artemisia annua raw material, pulverize it to 80 meshes, place it in a CO2 supercritical extraction tank for extraction, introduce liquid CO2, the flow rate is 1ml / min / g raw material, the extraction temperature is 50°C, the pressure is 22Mpa, and the extraction time is 3h. The extract was dissolved with 35 times the volume of 8% sodium bicarbonate solution. After the dissolved solution was filtered, an equal volume of petroleum ether was added and stirred thoroughly. The hydrochloric acid solution was adjusted to pH4. After 25 hours of crystallization, the crystals were recrystallized with anhydrous methanol and dried to obtain 3.4 g of artemisinic acid with a content of 97.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com