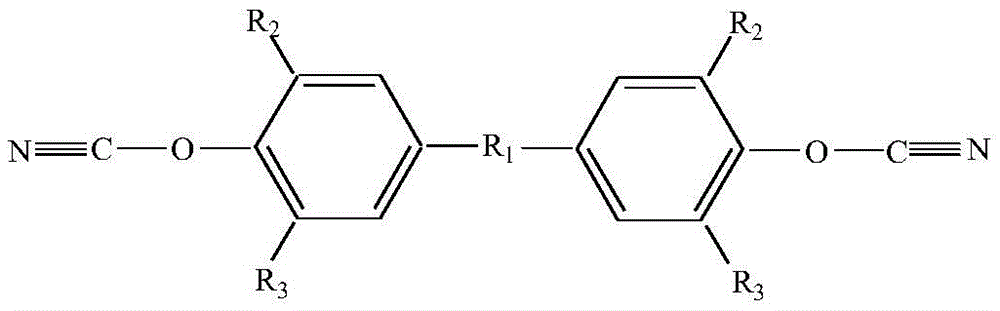

Cyanate ester composition and method for preparing copper-clad laminates using it

A technology of cyanate ester and composition, which is applied in the field of preparing copper clad laminates, can solve the problems of voids and white spots, poor adhesion between insulating materials and copper foil, polymers can not effectively fill the gap between prepreg and copper foil, etc. problem, to achieve excellent dielectric properties and improve compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

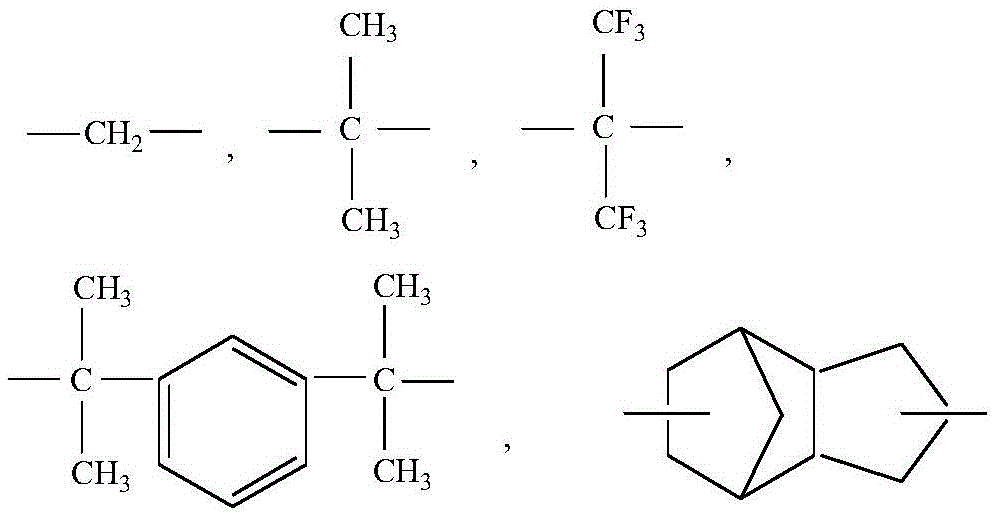

Method used

Image

Examples

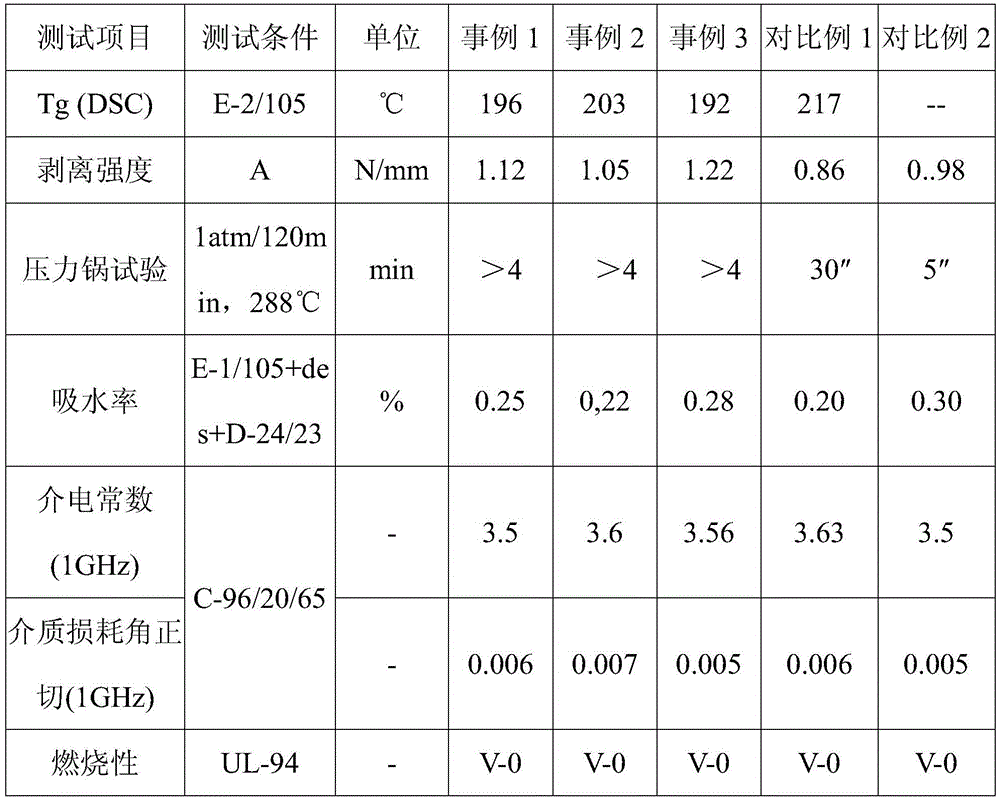

Embodiment 1

[0034] Add 100 parts of polyphenylene ether, 9.5 parts of bisphenol A, and then add 150 parts of toluene into a four-neck flask, heat to 100°C, and stir with a stirring bar until it dissolves and becomes transparent. 4 parts of benzoyl peroxide were dissolved in toluene, and dropped into the reaction vessel dropwise, and the reaction continued for 100 minutes. Nitrogen gas flow was maintained throughout the process. When the reaction is over, the product is precipitated with methanol and filtered to obtain a low-molecular-weight polyphenylene ether capped with phenolic hydroxyl groups.

[0035] Select 65 parts of the above polyphenylene ether, add 75 parts of toluene, stir and heat to 100°C until it is completely dissolved, add 35 parts of dicyclopentadiene monomer, and stir until the solution is uniform. Then add 100 parts of cyanate ester and 0.12 parts of organometallic salt catalyst while keeping the solution temperature at 97-103°C. After all the solutions are added, the...

Embodiment 2

[0037] Add 100 parts of polyphenylene ether, 9.5 parts of bisphenol A, and then add 150 parts of toluene into a four-neck flask, heat to 100°C, and stir with a stirring bar until it dissolves and becomes transparent. 4 parts of benzoyl peroxide were dissolved in toluene, and dropped into the reaction vessel dropwise, and the reaction continued for 100 minutes. Nitrogen gas flow was maintained throughout the process. When the reaction is over, the product is precipitated with methanol and filtered to obtain a low-molecular-weight polyphenylene ether capped with phenolic hydroxyl groups.

[0038] Select 80 parts of the above polyphenylene ether, add 65 parts of toluene, stir and heat to 100°C until it is completely dissolved, add 20 parts of styrene monomer, and stir until the solution is uniform. Then add 100 parts of cyanate ester and 0.08 parts of organometallic salt catalyst while keeping the solution temperature at 97-103°C. After all the solutions are added, the solution ...

Embodiment 3

[0040] Add 100 parts of polyphenylene ether, 9.5 parts of bisphenol A, and then add 150 parts of toluene into a four-neck flask, heat to 100°C, and stir with a stirring bar until it dissolves and becomes transparent. 4 parts of benzoyl peroxide were dissolved in toluene, and dropped into the reaction vessel dropwise, and the reaction continued for 100 minutes. Nitrogen gas flow was maintained throughout the process. When the reaction is over, the product is precipitated with methanol and filtered to obtain a low-molecular-weight polyphenylene ether capped with phenolic hydroxyl groups.

[0041] Select 50 parts of the above polyphenylene ether, add 65 parts of toluene, stir and heat to 100°C until it is completely dissolved, add 100 parts of styrene monomer, and stir until the solution is uniform. Then add 100 parts of cyanate ester and 0.12 parts of organometallic salt catalyst while keeping the solution temperature at 97-103°C. After all the solutions are added, the solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com