A kind of collector for bauxite flotation and preparation method thereof

A collector and bauxite technology, applied in the field of metallurgy, can solve the problems of large dosage of flotation agents, high production cost, poor solubility, etc., achieve good selectivity and collection capacity, low surface tension, and easy defoaming Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

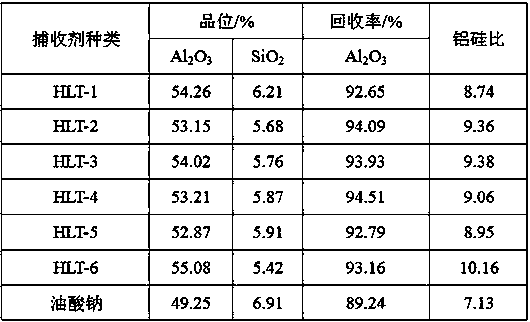

Examples

Embodiment 1

[0019] at 2m 3 In the reaction kettle, add 50 parts by weight of oleic acid, add 10 parts by weight of Tween80 under the action of mechanical stirring, and after stirring at a high speed of 3000r / min for 10 minutes, slowly add caustic soda aqueous solution (prepared by 10 parts by weight of caustic soda and 25 parts by weight of water) ), after 3000r / min high-speed stirring for 10min, add 10 parts by weight of naphthenic acid, then dropwise add 10 parts by weight of ethylamine, and finally add 3 parts by weight of dimethicone, and stir at 3000r / min at 15°C for 30 minutes to obtain The yellow oily liquid is the collector and is marked as HLT-1.

Embodiment 2

[0021] at 2m 3 In the reactor, add 50 parts by weight of oleic acid, add 12 parts by weight of Triton X-100 under mechanical stirring, after stirring at a high speed of 3000r / min for 10min, slowly add caustic soda aqueous solution (10 parts by weight of caustic soda and 25 parts by weight of water After stirring at a high speed of 3000r / min for 10min, add 10 parts by weight of naphthenic acid, then dropwise add 12 parts by weight of n-propylamine, and finally add 3 parts by weight of dimethylpolysiloxane, and stir at a high speed of 3000r / min at 15°C After 20 minutes, a yellow oily liquid was obtained, which was the collector and was designated as HLT-2.

Embodiment 3

[0023] at 2m 3 In the reaction kettle, add 50 parts by weight of tall oil, add 15 parts by weight of Tween20 under the action of mechanical stirring, after stirring at a high speed of 3000r / min for 10min, slowly add caustic soda aqueous solution (prepared by 10 parts by weight of caustic soda and 25 parts by weight of water) into), after 3000r / min high-speed stirring for 10min, add 10 parts by weight of naphthenic acid, then dropwise add 15 parts by weight of n-propylamine, and finally add 3 parts by weight of dimethyl polysiloxane, stir at 3000r / min at 15°C for 30 minutes, Obtained yellow oily liquid, which is the collector, marked as HLT-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com