A kind of in-situ self-generated al4la whisker reinforced magnesium-based composite material and its preparation method

An in-situ self-generated and composite material technology, applied in the field of magnesium-based composite materials, can solve the problems of poor interfacial bonding force and compatibility of composite materials, improve the comprehensive mechanical properties of materials, increase the nucleation rate, and refine The effect of alloy grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The chemical composition (mass percentage) of the composite material is: 4%La, 3%Al, 4%Li, the total amount of impurity elements Fe, Cu, Ni, Si is less than 0.03%, and the balance is Mg.

[0025] The melting and casting process for preparing the alloy is as follows: first, weigh the materials according to the proportion, put the Mg, Al, Li, Mg-30%La master alloy into the crucible to prepare for melting, then vacuumize the melting furnace to a vacuum degree of 4Pa, and then fill into argon protective gas. After preheating the melting furnace, keep it warm for 35 minutes. When the alloy in the crucible is fully melted, cast it with a cooling rate of 7°C / s. The resulting castings were homogenized at 400°C for 8 hours and then air-cooled.

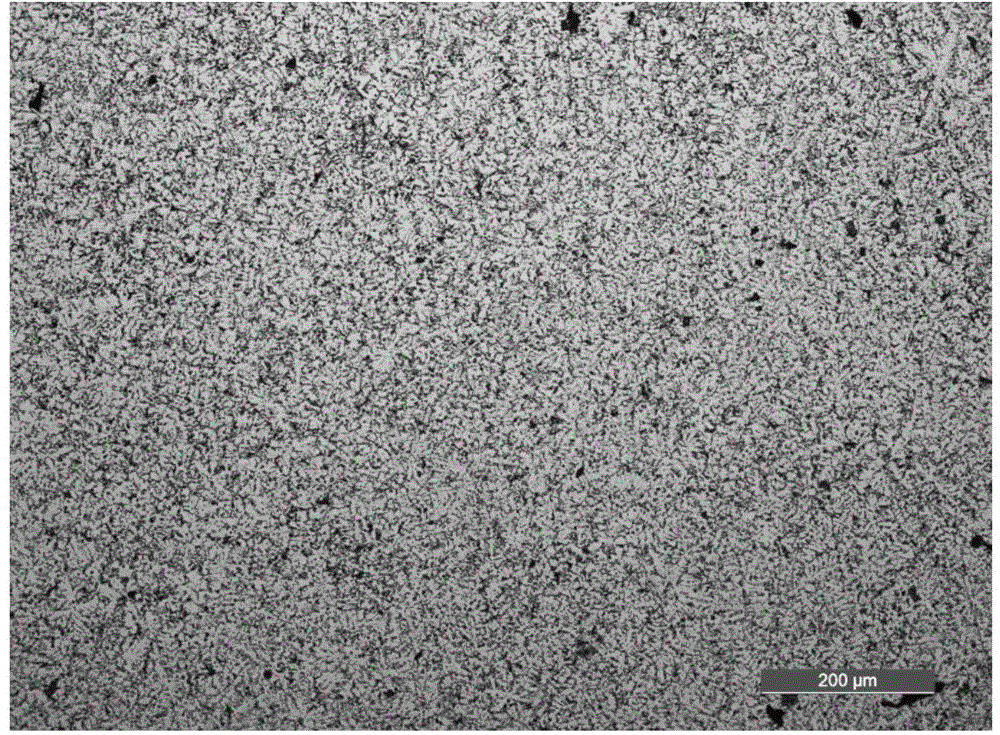

[0026] The in-situ self-generated Al in the as-cast state obtained in this embodiment 4 The microstructure of La whisker reinforced Mg-based composites is as follows: (1) The composite exhibits uniform fine grains and a high volume fra...

Embodiment 2

[0029] The chemical composition (mass percentage) of the composite material is: 4%La, 3%Al, 8%Li, the total amount of impurity elements Fe, Cu, Ni, Si is less than 0.03%, and the balance is Mg.

[0030] The melting and casting process for preparing the alloy is as follows: first, weigh the materials according to the proportion, put the Mg, Al, Li, Mg-30% La master alloy into the crucible to prepare for melting, then vacuumize the melting furnace until the vacuum degree reaches 3Pa, and then fill into argon protective gas. After preheating the melting furnace, keep it warm for 37 minutes. When the alloy in the crucible is fully melted, cast it with a cooling rate of 6°C / s. The resulting castings were homogenized at 350°C for 10 hours and then air-cooled.

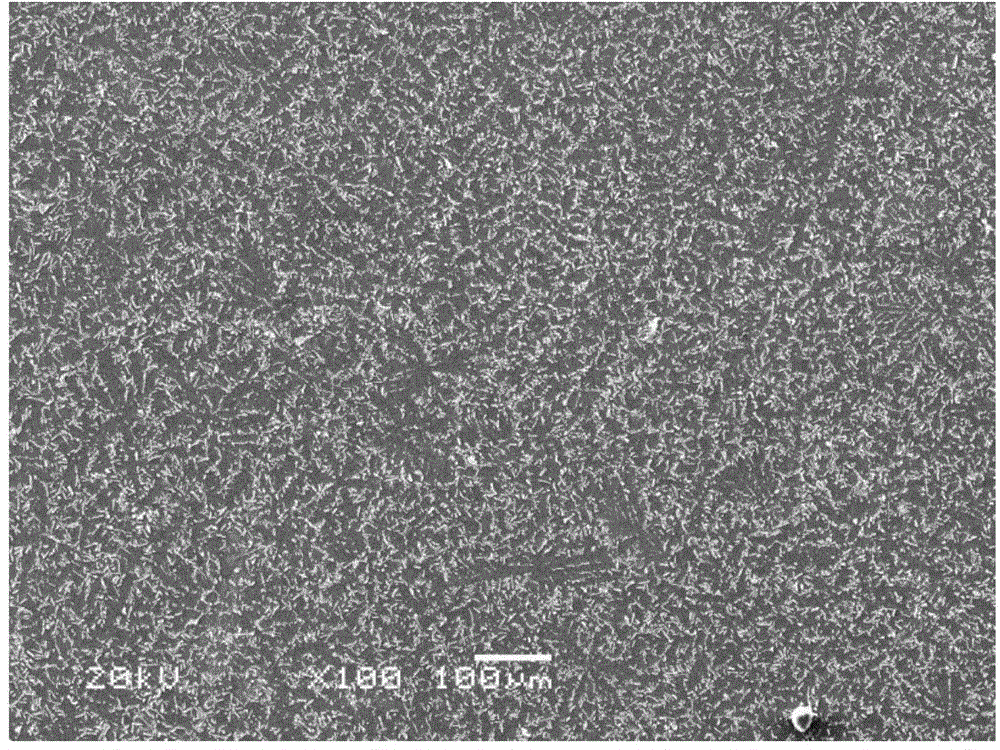

[0031] The in-situ self-generated Al in the as-cast state obtained in this embodiment 4 The microstructure of La whisker reinforced Mg-based composites is as follows: (1) The composite exhibits uniform fine grains and a hig...

Embodiment 3

[0034] The chemical composition (mass percentage) of the composite material is: 8% La, 6% Al, the total amount of impurity elements Fe, Cu, Ni, Si is less than 0.03%, and the balance is Mg.

[0035] The melting and casting process for preparing the alloy is as follows: firstly weigh the materials according to the proportion, put the Mg, Al, Li, Mg-30% La master alloy into the crucible to prepare for melting, then vacuumize the melting furnace until the vacuum degree reaches 2Pa, and then fill into argon protective gas. After preheating the melting furnace, keep it warm for 40 minutes. When the alloy in the crucible is fully melted, cast it with a cooling rate of 4°C / s. The resulting castings were homogenized at 420°C for 6 hours and then air-cooled.

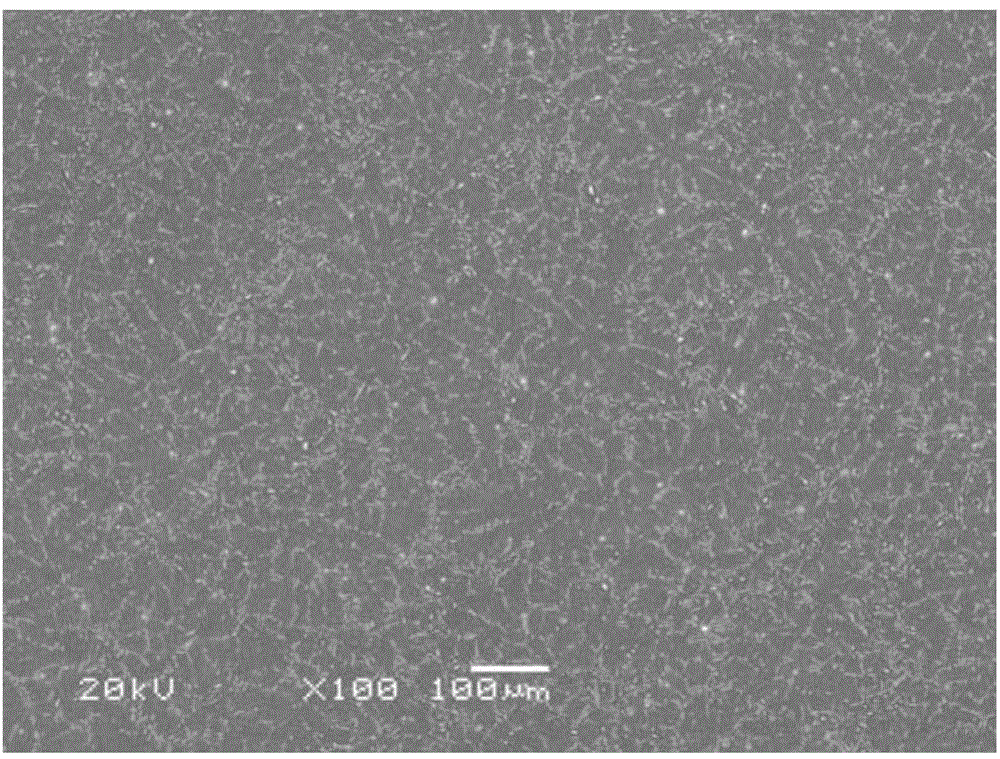

[0036] The in-situ self-generated Al in the as-cast state obtained in this embodiment 4 The microstructure of La whisker reinforced Mg-based composites is as follows: (1) The composite exhibits uniform fine grains and a high vo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com