Milky rust-proof liquid and preparation method thereof

A kind of antirust liquid and milky technology, which is applied in the field of milky antirust liquid and its preparation, can solve the problems of short antirust period, flammability, high concentration, etc., and achieve the effect of long antirust period and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

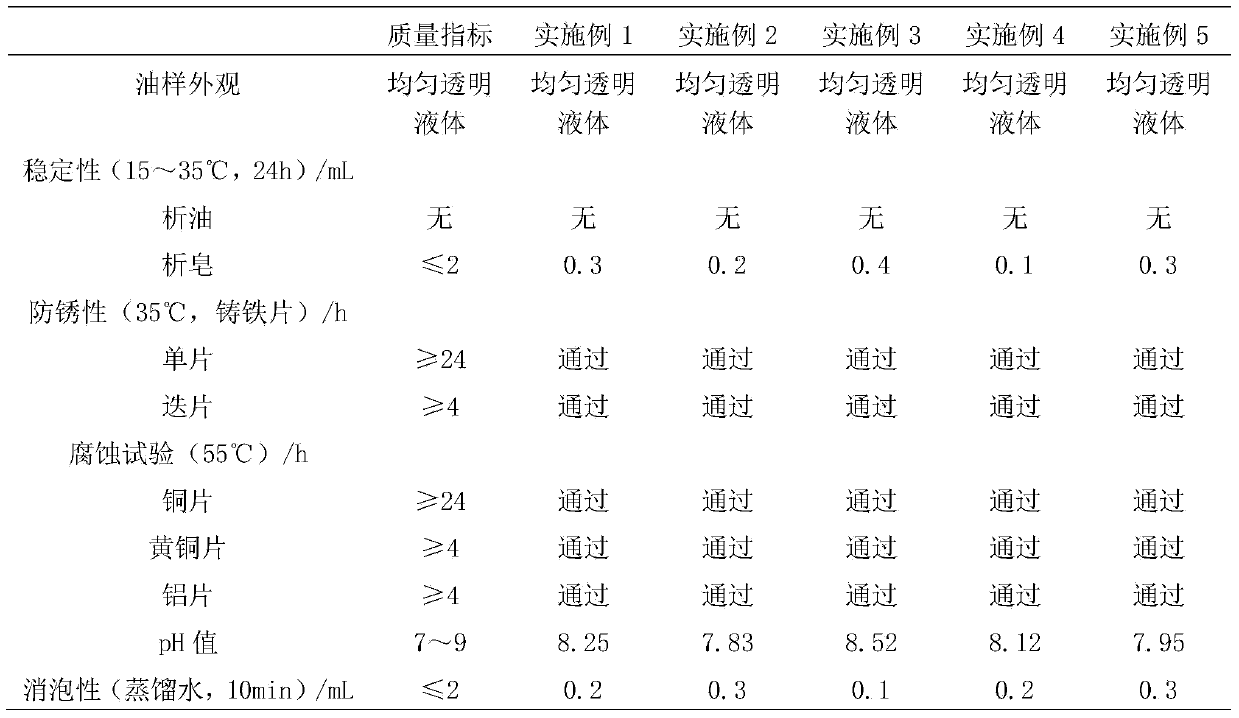

Examples

Embodiment 1

[0009] A milky antirust liquid, comprising by weight components: 10 parts of engine oil, 5 parts of barium petroleum sulfonate, 2 parts of iron naphthenate, 1 to 3 parts of fatty acid salt, 1 to 3 parts of sodium dodecylbenzenesulfonate 4 parts, 2-5 parts of triethanolamine oleate, 2-6 parts of OP-10, 0.2-0.8 parts of rosin resin, 0.1-0.5 parts of polyacrylate, 1-3 parts of silicone oil, 10-15 parts of water.

[0010] Add fatty acid salt, sodium dodecylbenzenesulfonate and triethanolamine oleate to the engine oil, stir while adding, then add water, raise the temperature to 80-85°C, stir and keep warm for 0.5h; then add oil Acid triethanolamine, OP-10, rosin resin, polyacrylate, silicone oil, continue to stir for 1 hour; finally add barium petroleum sulfonate and iron naphthenate, after they are completely dissolved, cool down naturally.

Embodiment 2

[0012] A milky antirust liquid, comprising by weight components: 12 parts of machine oil, 6 parts of barium petroleum sulfonate, 2 parts of iron naphthenate, 1 part of fatty acid salt, 1 part of sodium dodecylbenzene sulfonate, oil 2 parts of acid triethanolamine, 3 parts of OP-10, 0.3 parts of rosin resin, 0.2 parts of polyacrylate, 1 part of silicone oil, 11 parts of water.

[0013] The preparation method is the same as in Example 1.

Embodiment 3

[0015] A milky antirust liquid, comprising by weight components: 20 parts of machine oil, 7 parts of barium petroleum sulfonate, 3 parts of iron naphthenate, 2 parts of fatty acid salt, 3 parts of sodium dodecylbenzene sulfonate, oil 3 parts of acid triethanolamine, 4 parts of OP-10, 0.6 parts of rosin resin, 0.3 parts of polyacrylate, 2 parts of silicone oil, 14 parts of water.

[0016] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com