Outer wall stone-simulated decorative plate and manufacturing method thereof

A manufacturing method and decorative board technology, applied in the field of building decoration materials, can solve the problems of insufficient adhesion strength of the decorative coating, difficult installation, large deformation rate, etc., and meet the requirements of stone appearance effects, uniform color point distribution, Good acid and alkali resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

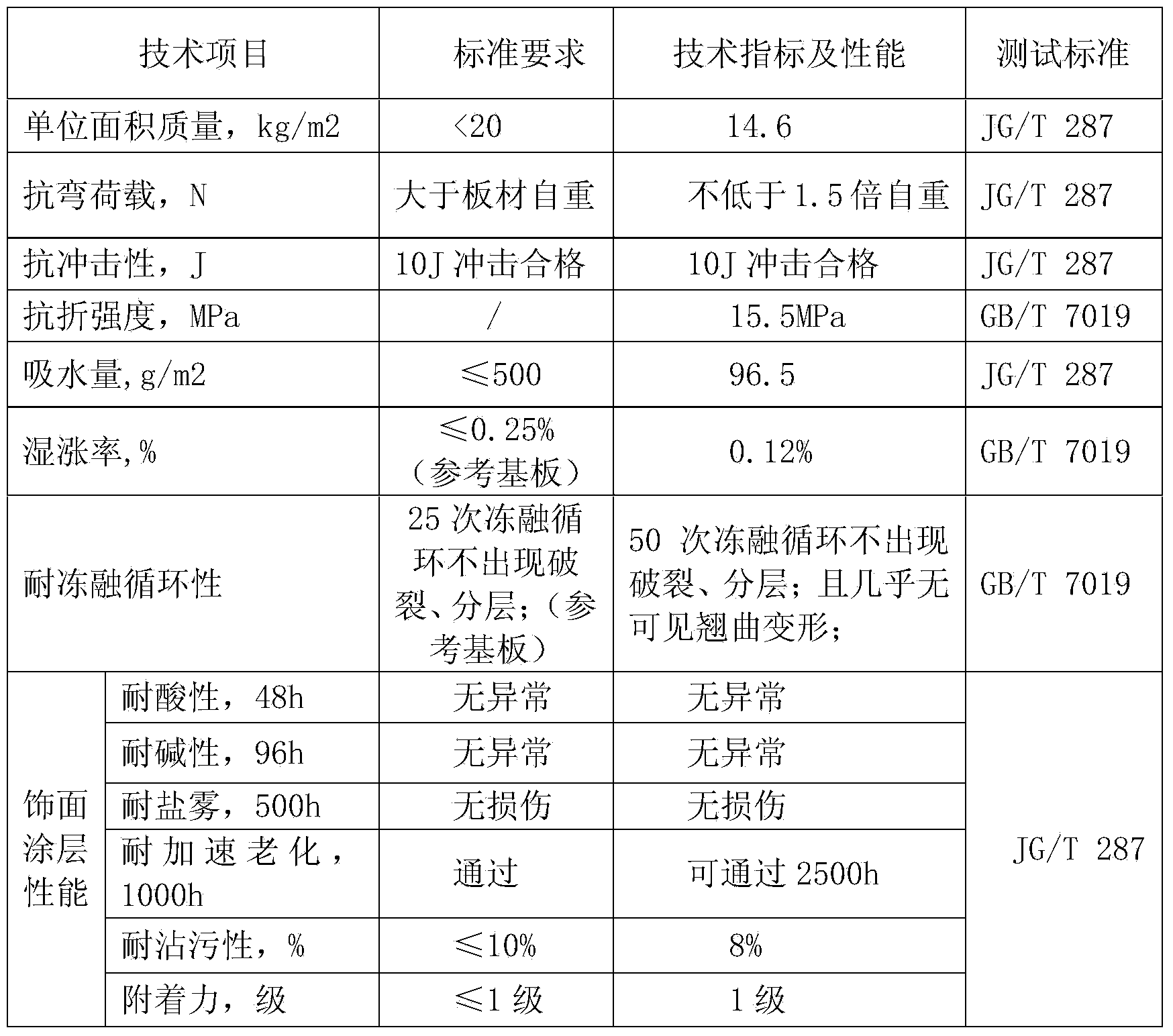

Embodiment 1

[0023] According to a kind of exterior stone-like decorative board and its manufacturing method described in the above-mentioned content of the invention, a substrate with a thickness of 9mm is selected, and a commonly used stone-like fluorine-silicon colorful stone-like coating system is randomly selected as the decorative effect coating. Layer, in strict accordance with the process steps and methods in the preparation method, the imitation stone decorative board for exterior walls described in this invention is prepared, and the stone imitation decorative board for exterior walls obtained is based on the standard JG / T287 "Insulation Decorative Board Exterior Wall External Thermal Insulation System Materials" , GB / T7019 "Test Methods for Fiber Cement Products", respectively for the mass per unit area, flexural strength, flexural load, impact resistance, water absorption, wet expansion rate, freeze-thaw cycle resistance (freeze resistance), decorative Surface coating performanc...

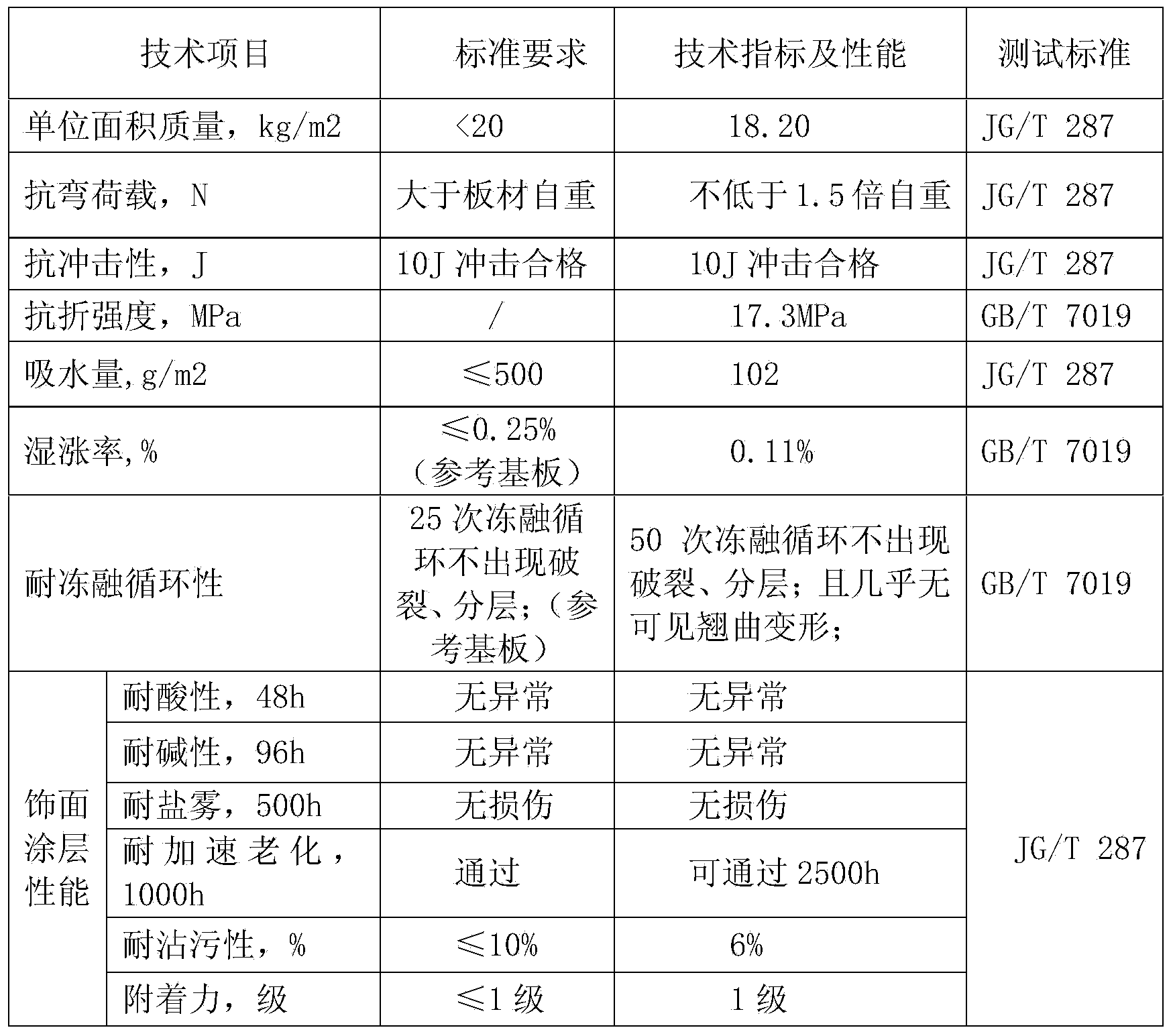

Embodiment 2

[0026] According to a kind of exterior stone-like decorative board and its manufacturing method described in the above-mentioned content of the invention, a substrate with a thickness of 12mm is selected, and a commonly used stone-like fluorosilicon colorful stone-like coating system is randomly selected as the decorative effect coating. layer, and strictly follow the process steps and methods in the preparation method to prepare the stone-like decorative board for exterior walls described in the invention. According to the standards JG / T287 "Materials for External Thermal Insulation System of Thermal Insulation Decorative Boards for Exterior Walls" and GB / T7019 "Test Methods for Fiber Cement Products", the obtained exterior wall imitation stone decorative panels are tested for mass per unit area, flexural strength, flexural load, Impact resistance, water absorption, wet expansion rate, freeze-thaw cycle resistance (freeze resistance), finish coating performance (acid resistanc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com