Environment-friendly, formaldehyde-removing, mold-proof and anti-bacterial wallpaper

An anti-mildew, anti-bacterial, and environment-friendly technology, applied in anti-fouling/underwater coatings, lamination, coating, etc., can solve the problems of easy aging, non-abrasion resistance, inconvenient cleaning and construction, etc., and achieve good environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

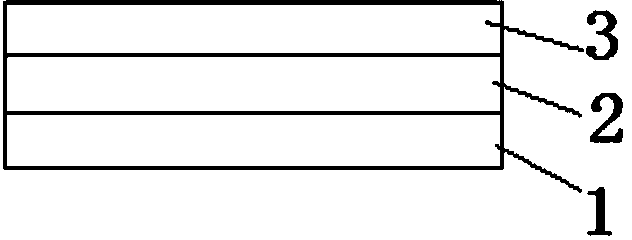

[0025] According to this embodiment, an environmentally friendly formaldehyde-removing mildew-proof and antibacterial wallpaper is characterized in that it includes a base layer 1, an adsorption layer 2 is provided on the surface of the base layer 1, and a coating layer 3 is provided on the surface of the adsorption layer 2 , the adsorption layer 2 is provided with an adsorbent, and the coating layer 3 is composed of the following materials in mass percentage: PVC: 35 parts, nano-TiO 2 : 3 parts, nano ZnO: 3 parts, fungicide zinc pyrithione: 3 parts, negative ion powder: 10 parts, titanium dioxide: 4 parts, natural gypsum: 8 parts, and the rest is deionized water.

[0026] The adsorbent used in the adsorption layer 2 is activated carbon.

[0027] The preparation method of the environment-friendly formaldehyde-removing mildew-proof and antibacterial wallpaper is as follows:

[0028] The adsorption layer 2 and the base layer 1 are compression-molded by a compression molding ma...

Embodiment 2

[0030] According to this embodiment, an environmentally friendly formaldehyde-removing mildew-proof and antibacterial wallpaper is characterized in that it includes a base layer 1, an adsorption layer 2 is provided on the surface of the base layer 1, and a coating layer 3 is provided on the surface of the adsorption layer 2 , the adsorption layer 2 is provided with an adsorbent, and the coating layer 3 is composed of the following materials in mass percentage: PVC: 40 parts, nano-TiO 2 : 2 parts, nano ZnO: 4 parts, fungicide zinc pyrithione: 3 parts, negative ion powder: 10 parts, titanium dioxide: 5 parts, natural gypsum: 8 parts, and the rest is deionized water.

[0031] The adsorbent used in the adsorption layer 2 is a mixture of diatomaceous earth and activated carbon, and the ratio of the two is 1:2.

[0032] The preparation method of the environment-friendly formaldehyde-removing mildew-proof and antibacterial wallpaper is as follows:

[0033] The adsorption layer 2 an...

Embodiment 3

[0035] According to this embodiment, an environmentally friendly formaldehyde-removing mildew-proof and antibacterial wallpaper is characterized in that it includes a base layer 1, an adsorption layer 2 is provided on the surface of the base layer 1, and a coating layer 3 is provided on the surface of the adsorption layer 2 , the adsorption layer 2 is provided with an adsorbent, and the coating layer 3 is composed of the following materials in mass percentage: PVC: 45 parts, nano-TiO 2 : 2 parts, nano ZnO: 6 parts, fungicide zinc pyrithione: 4 parts, negative ion powder: 15 parts, titanium dioxide: 4 parts, natural gypsum: 5 parts, and the rest is deionized water.

[0036] The adsorbent used in the adsorption layer 2 is diatomaceous earth.

[0037] The preparation method of the environment-friendly formaldehyde-removing mildew-proof and antibacterial wallpaper is as follows:

[0038] The adsorption layer 2 and the base layer 1 are compression-molded by a compression molding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com