Dual-cluster hydraulic jet tubular column and dual-cluster hydraulic jet annulus fracturing method

A hydraulic jet and annular fracturing technology, applied in the field of oil well fracturing, can solve the problems of long auxiliary time, environmental pollution, and high risk of tripping the pipe string, and achieve the effects of improving efficiency, reducing danger, and increasing displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to overcome the current double-cluster fracturing of oil wells and horizontal wells, there are frequent tripping strings, replacement of drilling tools, long auxiliary construction time, high risks in the process of tripping strings, and the defects of environmental pollution.

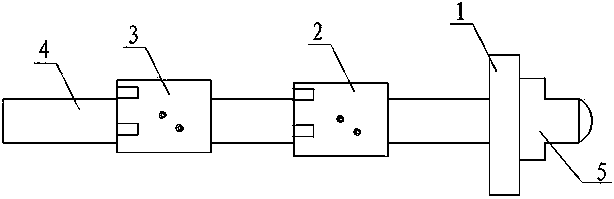

[0019] To this end, the present invention provides a figure 1 The double-cluster hydrojet string shown includes a packer 1 (the outer end of the packer 1 is provided with a centralizer 5), a single-stage spray gun 2 and a sliding sleeve spray gun 3 arranged in sequence on the string, and the sealed The packer 1 is set at one end of the pipe string 4, and the single-stage spray gun 2 is set between the packer 1 and the sleeve spray gun 3. The packer 1 is a CTY-211 packer with a check valve. Its rubber cartridge is resistant to high temperature and high pressure, prolonging the service life of the tool.

[0020] At the same time, it provides a double-cluster hydraulic jet annulus fractur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com