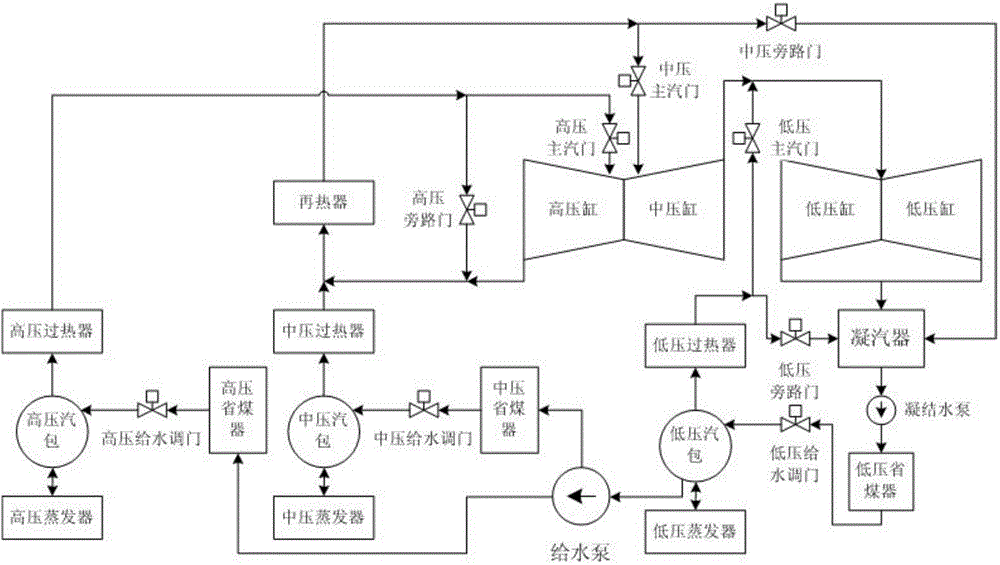

Method and device for improving reliability of starting water level of heat recovery boiler of gas turbine power plant

A technology for waste heat boilers and power plants, applied to steam boiler components, steam boilers, steam boiler accessories, etc., can solve problems such as rising water level of waste heat boiler drums and missed intervention opportunities by monitoring personnel, and achieve fast regulation and efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

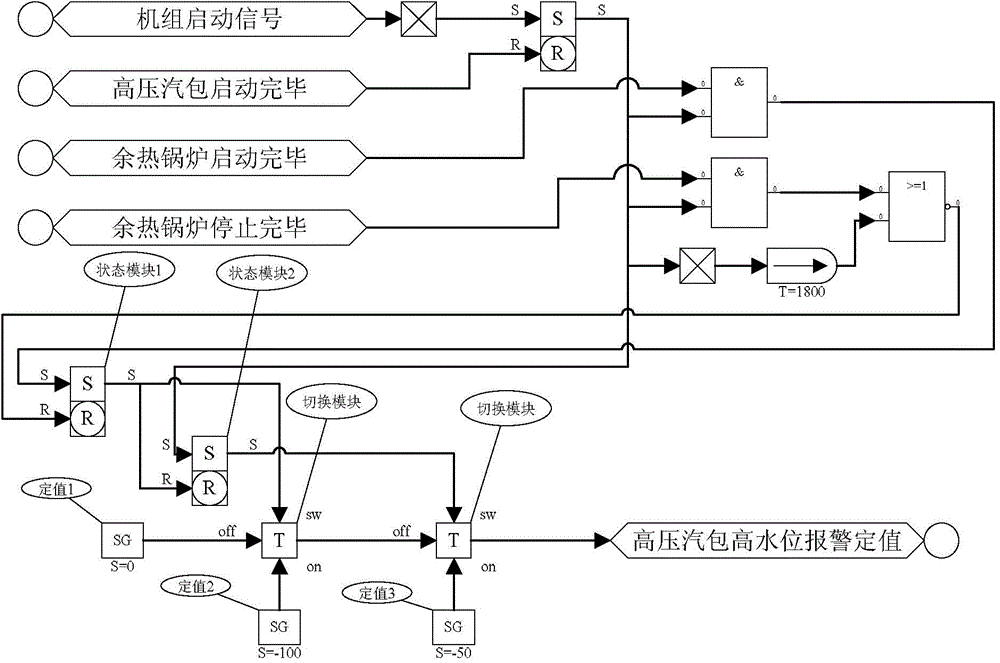

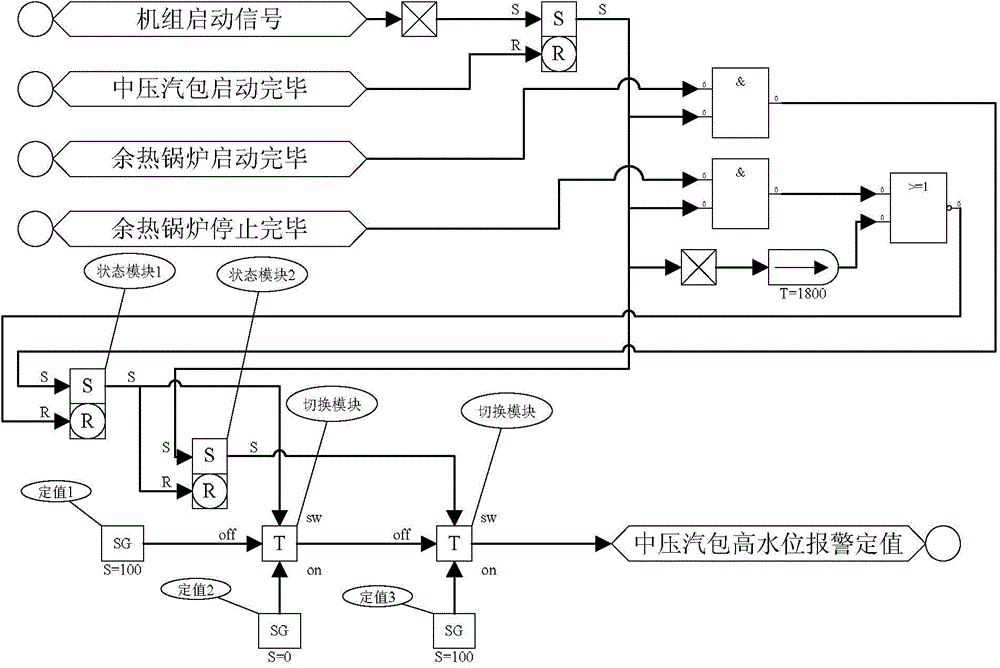

[0028] Reference figure 2 with image 3 , The device for improving the start-up water level reliability of the waste heat boiler of a gas turbine power plant in this embodiment includes a waste heat boiler start-up unit, a medium / high pressure drum start unit and a drum high water level alarm circuit, and the output of the medium / high pressure drum start unit The terminal is connected to the input terminal of the waste heat boiler starting unit; a logic control device is provided between the output terminal of the waste heat boiler starting unit of the gas turbine power plant and the input terminal of the drum high water level alarm loop. The logic control device includes a startup state module 1 , Shutdown state module 2, one of switching modules, two of switching modules, one of fixed value modules, two of fixed value modules and third of fixed value modules, the S and R signal input terminals of start state module 1 are connected to waste heat boiler One output terminal of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com