Method using photographic density value to measure homogeneous material thickness

A technology of material thickness and blackness, applied in measuring devices, using wave/particle radiation, instruments, etc., can solve the problems of high price and large amount of invested capital, saving purchase costs, strong applicability, and improving detection quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0044] Take a large aluminum alloy precision casting in the shape of a truncated cone as an example, hereinafter referred to as aluminum castings such as Figure 4 shown;

[0045] In the first step, the thickness of the aluminum casting is estimated to be 12-17mm;

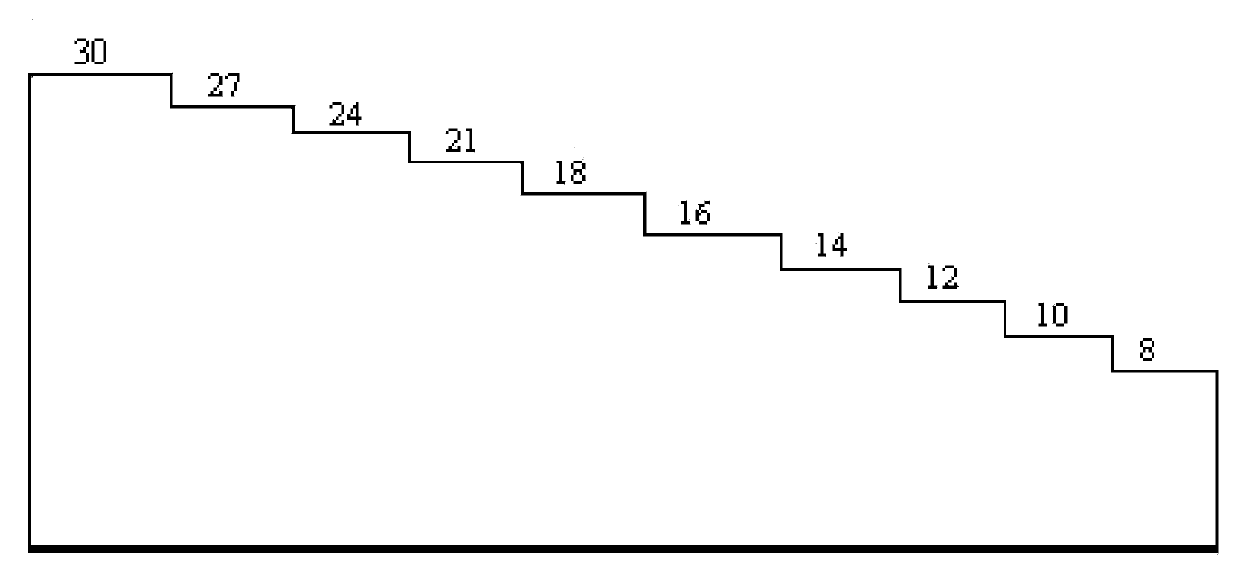

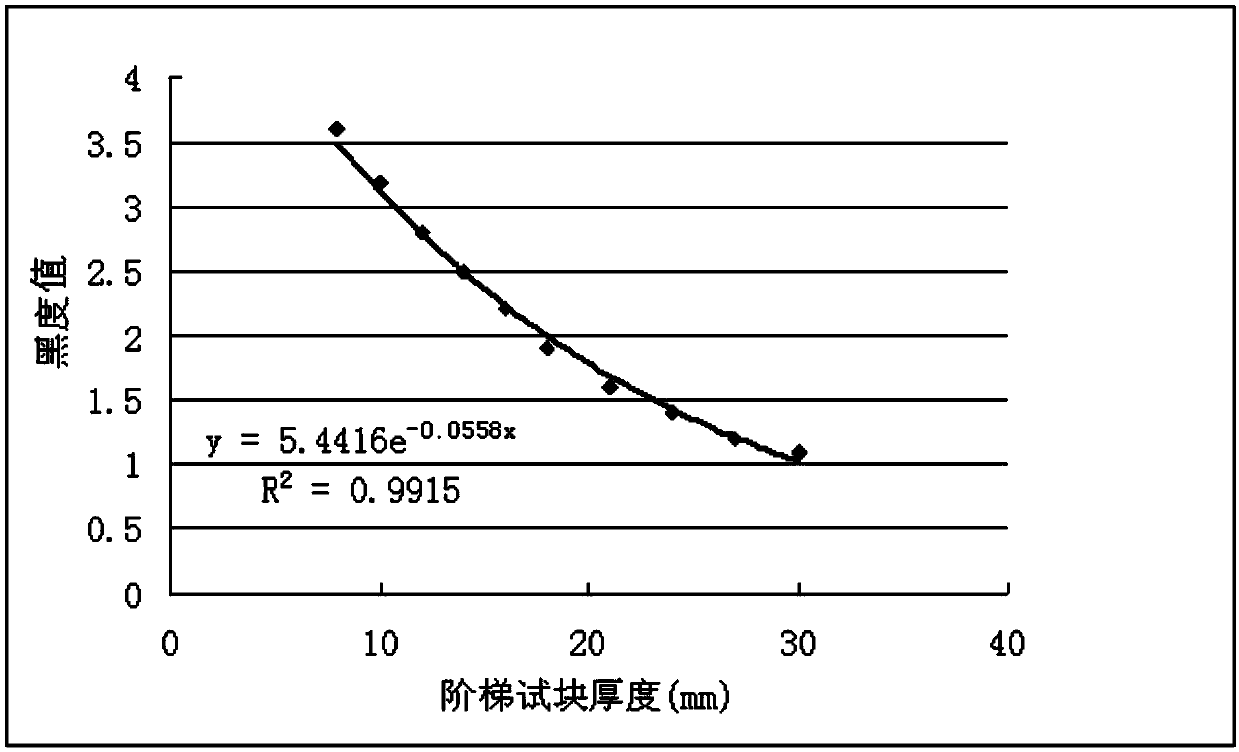

[0046] The second step is to select a standard ladder test block made of aluminum, such as figure 1 As shown, there are 10 steps, and their heights from high to low are 30mm, 27mm, 23mm, 21mm, 18mm, 16mm, 14mm, 12mm, 10mm, 8mm;

[0047] The third step is to select the X-ray radiographic parameters for the aluminum material standard ladder test block as follows:

[0048] Transillumination tube voltage 70Kev, tube current 20mA, exposure time 1Min, focal length 1000mm; film system: film AgFa D7, developer and fixer are "Tianhai set medicine", developing time 3Min, fixing time 5Min, developing temperature 28℃;

[0049] The fourth step is to arrange the radiographic film, and use the parameters of the third step to p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com