Method for detecting residual quantity of N, N-dimethyl formamide in PU (Polyurethane) leather

A technology of dimethylformamide and residue, which is applied in the field of N,N-dimethylformamide, can solve the problems of analysis error, influence of DMF detection, inability to directly detect, etc., and achieve high accuracy and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

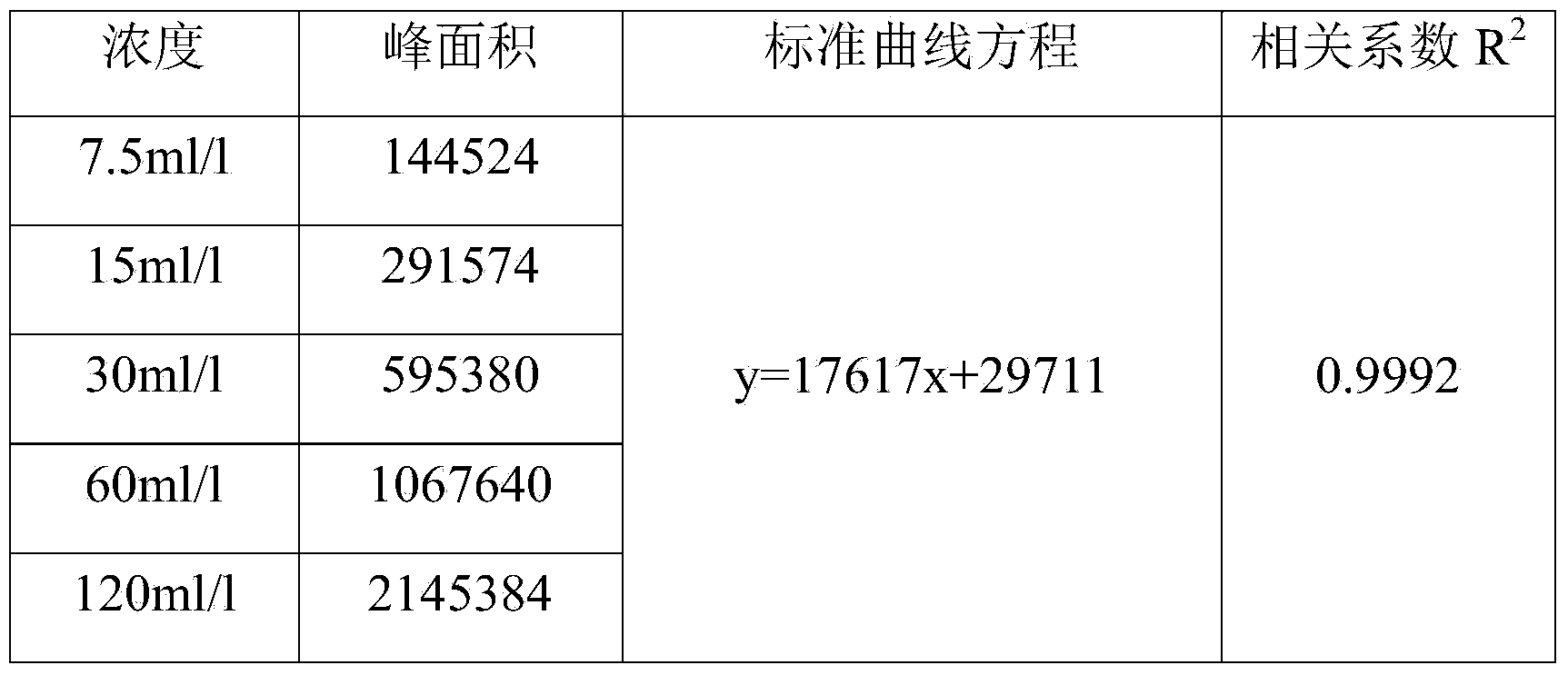

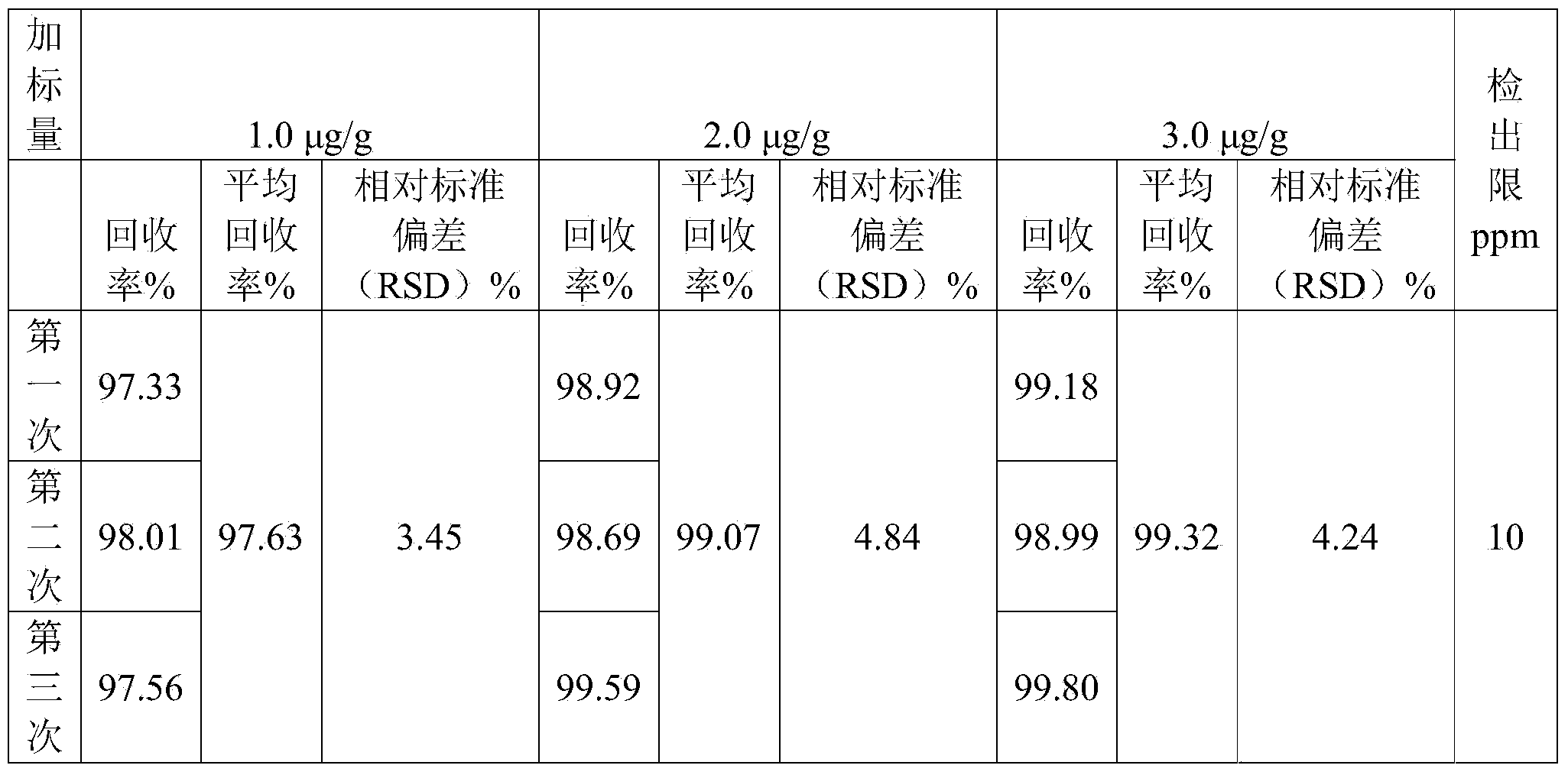

Examples

Embodiment 1

[0034] The sample used: PU leather for clothing (0.5mm thick, blue) (provided by Zhejiang Hexin Industrial Group Co., Ltd.)

[0035] 1. Detection of DMF residues in PU leather for clothing (0.5mm thick, blue)

[0036] step 1:

[0037] Weigh 5.00g of the above-mentioned PU leather sample, cut it into pieces of about 1mm×1mm in size, place it in a 100ml conical flask with a stopper, and add 55ml of N-n-butyl-N-methylimidazolium tetrafluoroethylene to the conical flask Borate ionic liquid was used as the extraction solvent, and the stopper was sealed; then the conical flask was fixed in an ultrasonic extraction apparatus, and ultrasonic extraction was performed at 70°C for 1 hour. After the extraction was completed, it was filtered to obtain the ionic liquid extract of DMF , as the sample solution to be tested.

[0038] Step 2:

[0039] (1) Prepare a blank solution:

[0040] Preparation of DMF-free PU leather samples: Cut the above PU leather into pieces of about 1mm×1mm in s...

Embodiment 2-13

[0071] According to the same detection method as in Example 1, the DMF content of the PU leather samples shown in Table 3 was detected, and the results are shown in Table 3.

[0072] Table 3: Experimental data of embodiments 2-13

[0073] Example

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com