Package lead frame

A technology for encapsulating leads and frames, which is applied in the direction of electrical components, electrical solid devices, circuits, etc. It can solve the problems of low yield, poor stability, and easy falling off of plastic packages and carriers for electronic components, achieving stable combination and shock resistance The effect of prolonging the sex and improving the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

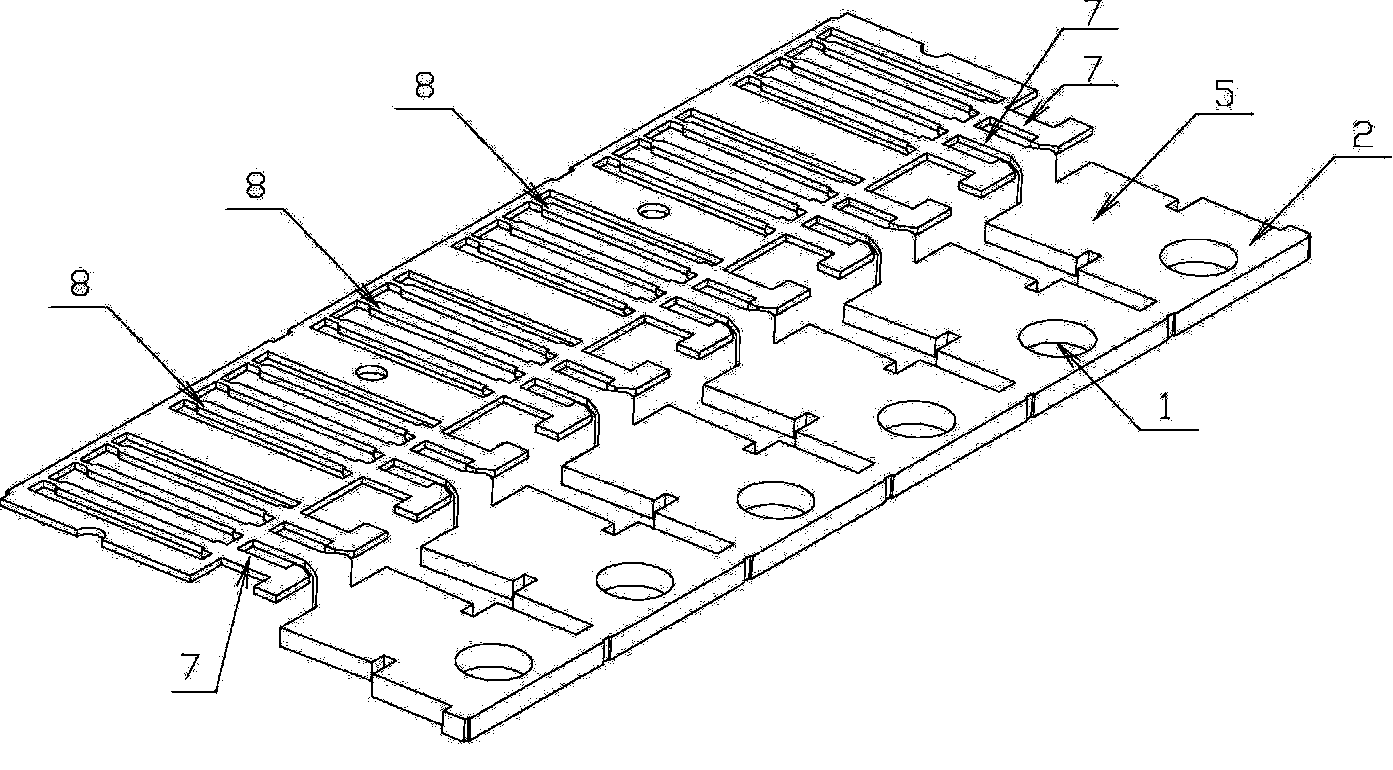

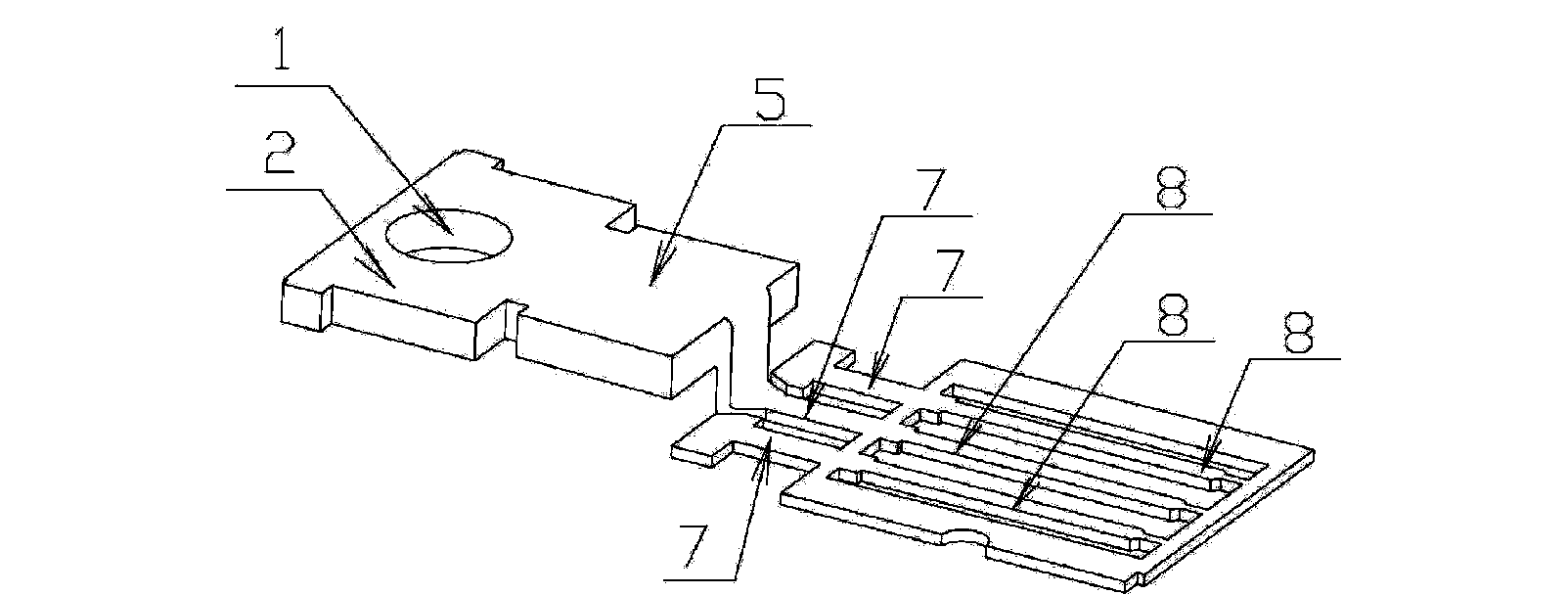

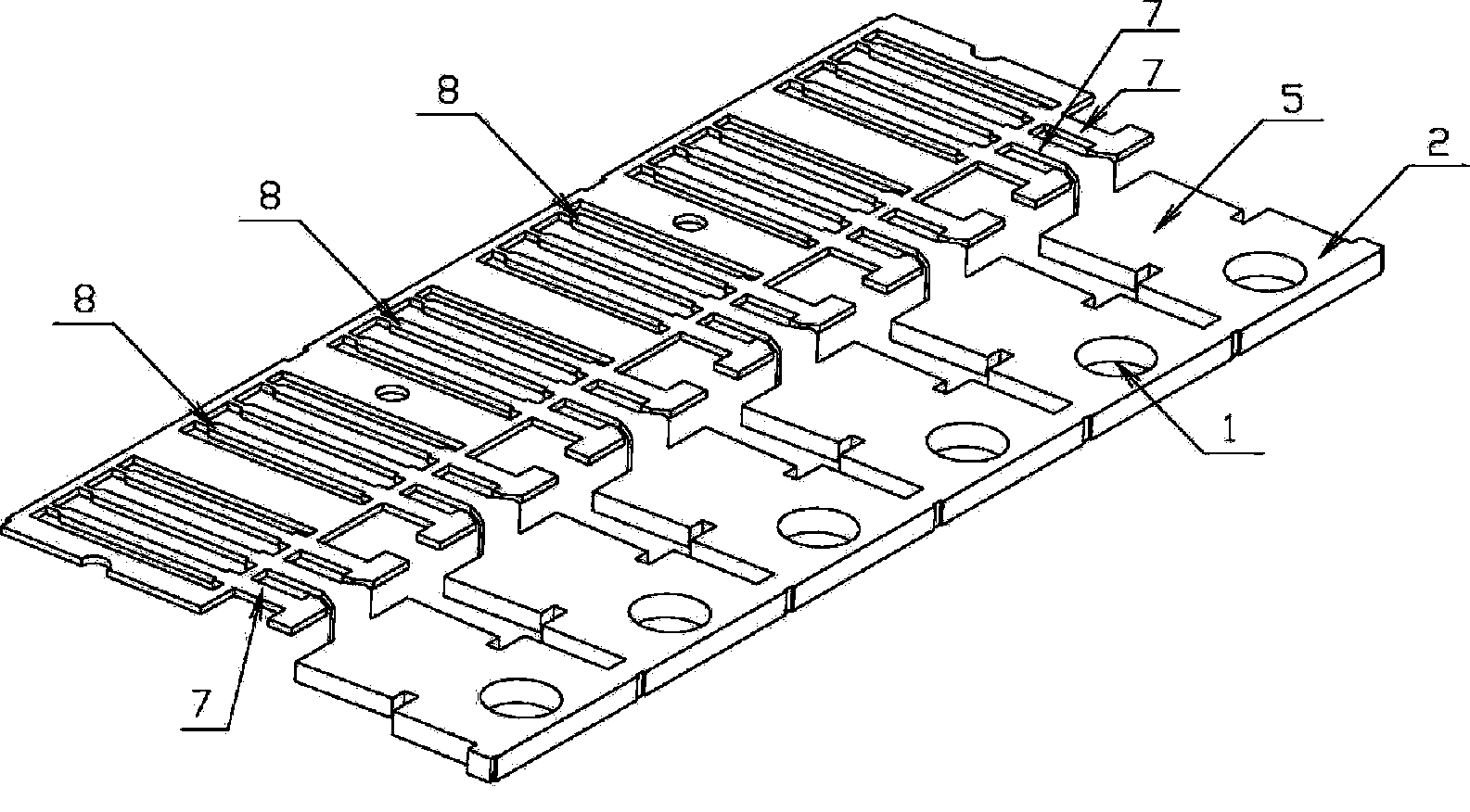

[0022] like Figure 3-8 As shown, the package lead frame is formed by continuous arrangement of several copper-based units, and each copper-based unit includes a heat sink 2, a carrier sheet 5, an inner lead 7 and an outer lead 8 connected in sequence; the heat sink 2 Positioning holes 1 are provided on the top; the connection between the heat sink 2 and the carrier 5 is a plane transition with the front of the carrier 5; the inner lead 7 and the outer lead 8 are plane transitions; the heat sink 2 and the carrier 5 A dovetail groove 3 is provided at the connection, and the dovetail groove 3 is arranged on the front of the copper-based unit; a U-shaped groove 4 is arranged on the front of the carrier 5; a V-shaped groove 6 is arranged on the inner lead 7, and the V-shaped Groove 6 is set on the front side of inner lead 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com