A kind of superjunction mosfet device and its manufacturing method

A manufacturing method and device technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems affecting device reliability, increase circuit power consumption, increase device leakage, etc., and increase manufacturing costs and process difficulties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The specific embodiments of the present invention will be further described below in conjunction with the drawings.

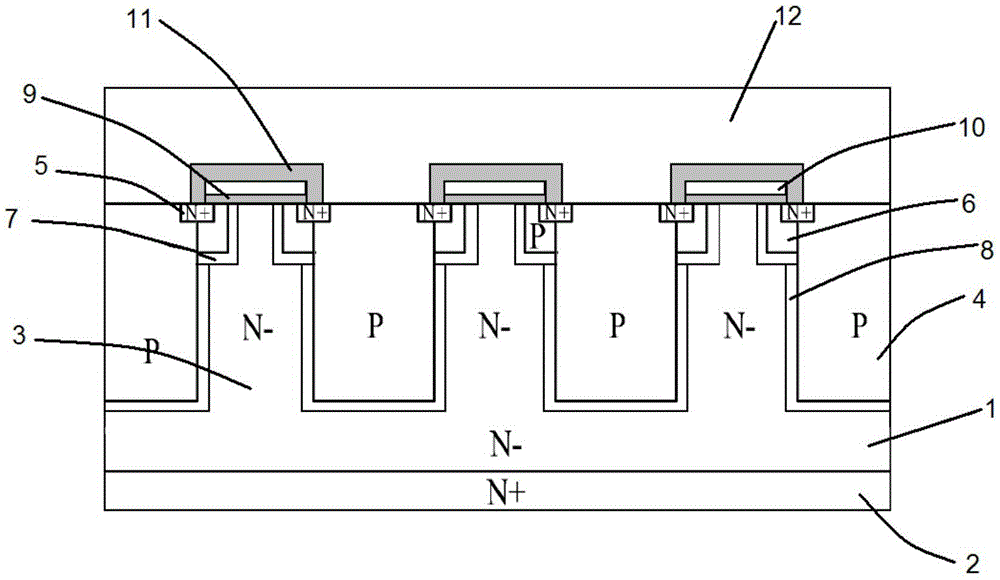

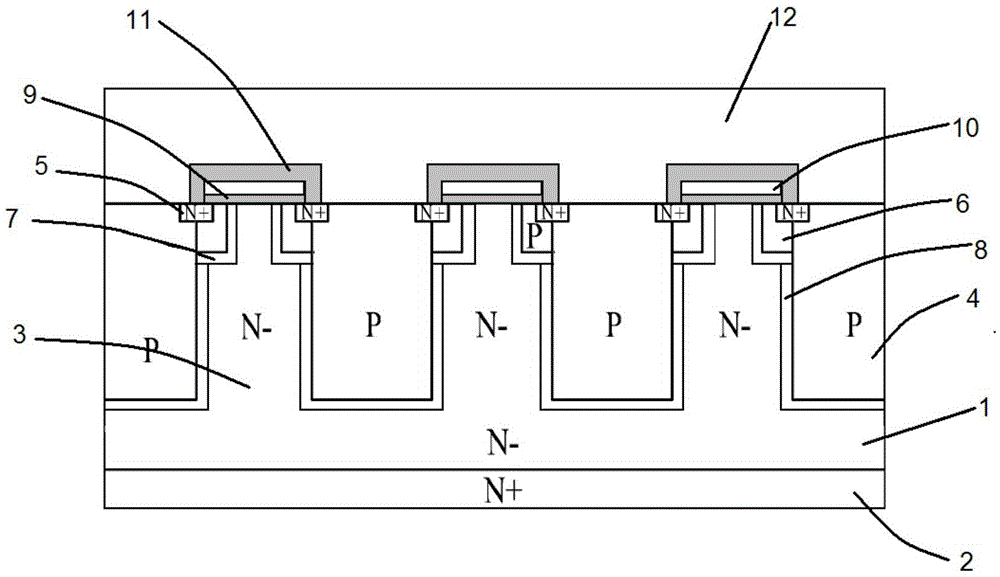

[0057] Such as image 3 As shown, taking an N-type super junction MOSFET device as an example, on the cross-section of the MOSFET device, the semiconductor substrate includes an N-type drift layer 1 and an N+ type substrate 2 located below the N-type drift layer 1. The N+ type substrate 2 Adjacent to the N-type drift layer 1, the concentration of the N+ type substrate 2 is greater than that of the N-type drift layer 1.

[0058] On the cross section of the MOSFET device, the N-type drift layer 1 includes a plurality of pairs of first pillars with N-type conductivity and second pillars with P-type conductivity, that is, N-type pillars 3 form a first The P-type pillar 4 forms the second pillar. The N-type pillars 3 and the P-type pillars 4 are alternately arranged in the N-type drift layer 1 to form a super junction structure. The N-type pillar 3 and the P-typ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com