Apparatus for the automated testing and validation of electronic components

一种自动测试装置、电子元件的技术,应用在自动测试和验证电子元件的装置,基于MEMS系统接口模块的装置领域,能够解决破坏定时测量精度和测试结果、降低信号完整性等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

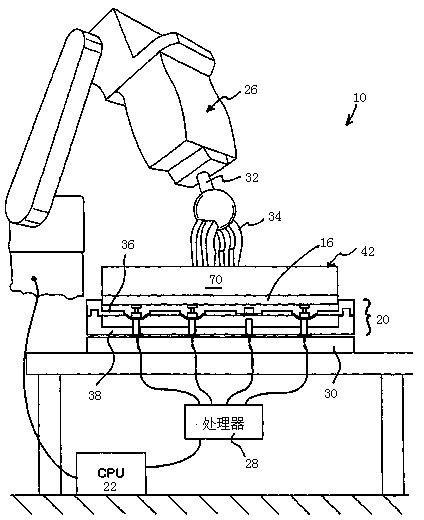

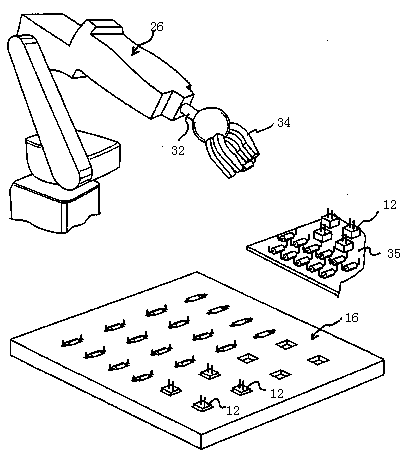

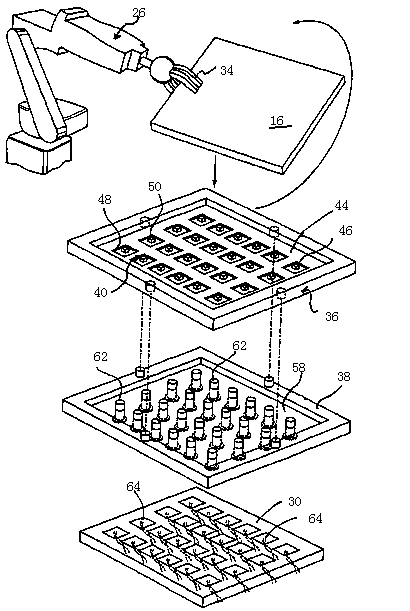

[0031] refer to figure 1 , which shows an automatic test equipment 10 unit for the automated testing and verification of electronic components 12 ( figure 2 ), preferably simultaneously testing a plurality of components 12 fixed to the test mold 16 before the component 12 is assembled as part of a circuit board and / or the like. The automatic test apparatus 10 as will be described is provided with a large interactive system configured to enable simultaneous high-speed testing of many different types of electronic components 12 including, by way of non-limiting example, switches, chips, resistors, diodes, etc., There is no need for significant specific customization of the mobile device and / or reconfiguration for each different mold or unit under test 16 .

[0032] exist figure 1 As shown in the large-scale interactive system 20 , the automatic test device 10 includes a main processor 22 , robotic manipulation components 26 , a test protocol controller 28 , and an interactive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com