Household grain tedder

A technology of tumbler and grain, applied in dryers, drying solid materials, non-progressive dryers, etc., can solve the problems of grain nutrition loss, difficult to control heating temperature, and large energy consumption, so as to improve work efficiency, Reduce labor intensity and labor demand, the effect of strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

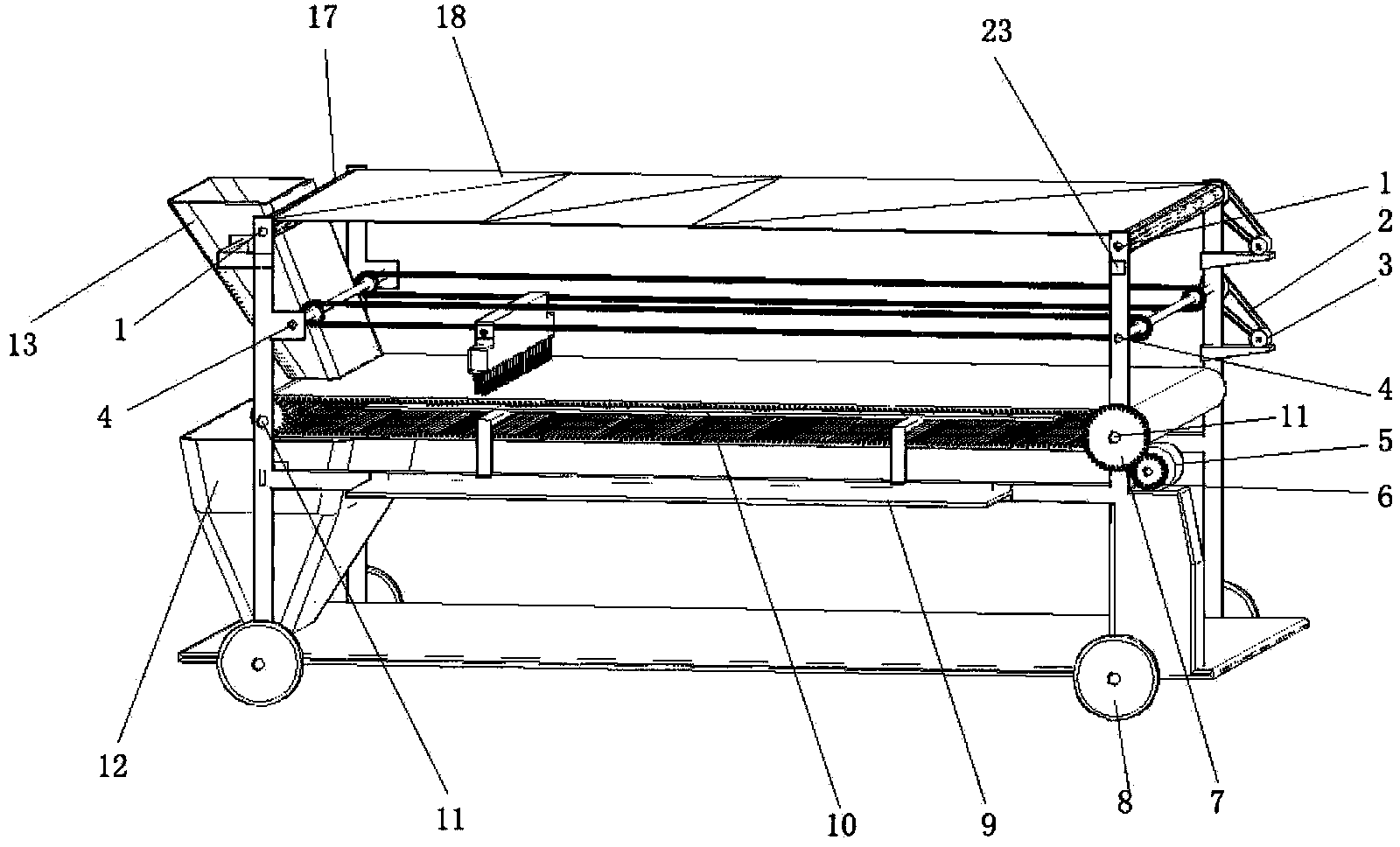

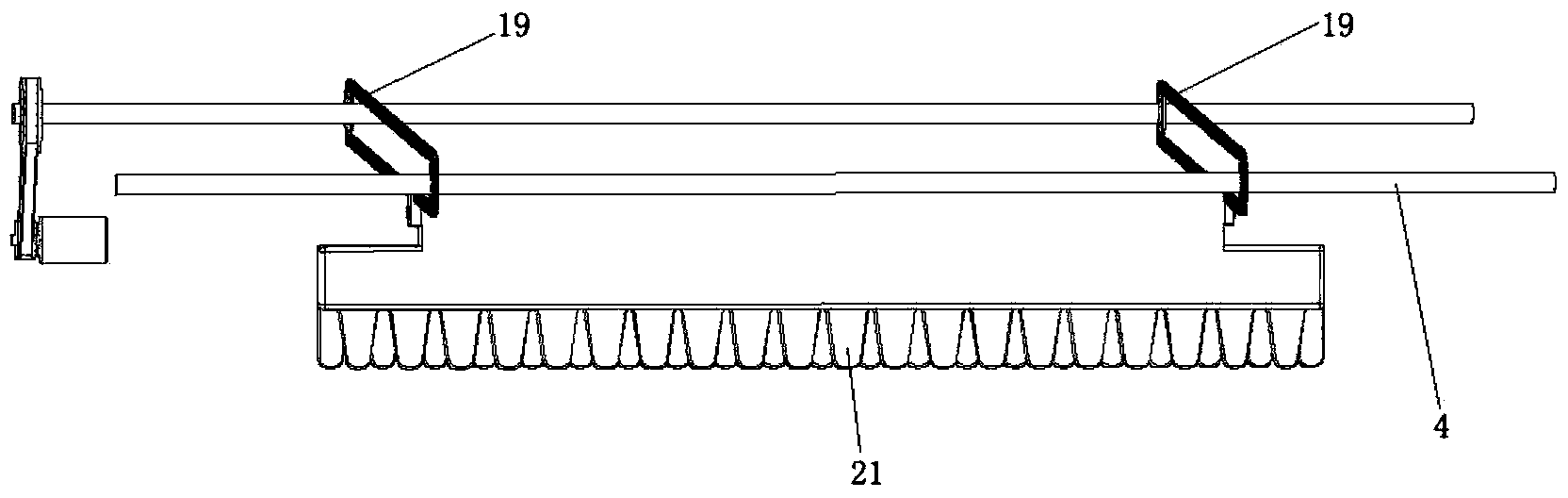

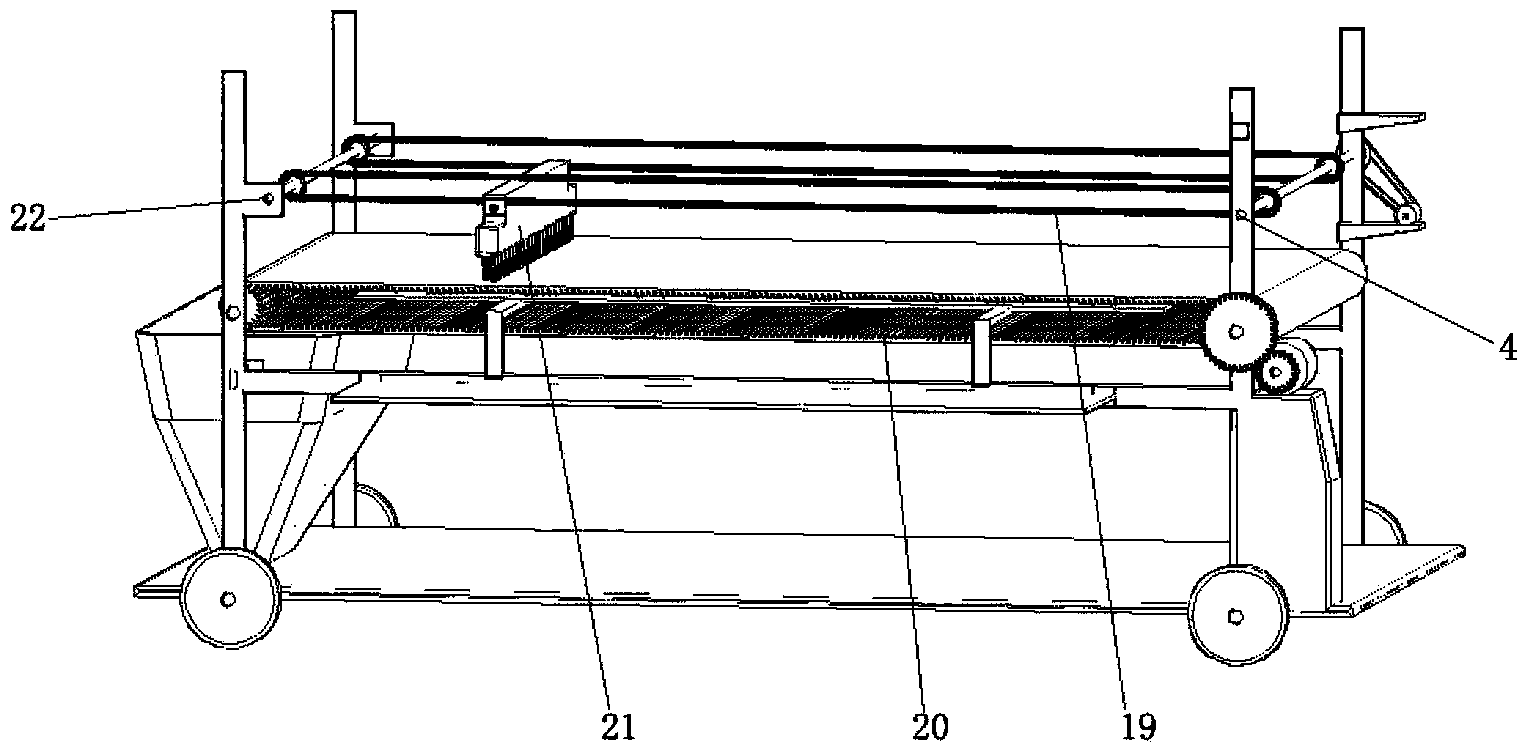

[0025] Attached below Figure 1-7 A kind of grain turning device of the present invention is described further.

[0026] A household grain tanning machine comprises a support frame 24, a transmission device, a tumbling device, a drying device and a rainproof device. The support frame 24 is provided with a drying device, a transmission device, a valley turning device and a rainproof device successively from bottom to top. This tedder is also provided with feed inlet 13 and harvest box 12, is respectively arranged on the top and the bottom of one end of transmission device.

[0027] The grain tanning part in the present invention includes a transmission device and a valley turning device.

[0028] The transmission device includes a conveyor belt 20, a first screw 11, a bevel gear 6, a bevel gear 7, a first drive motor 5 and other components. The first driving motor 5 provides the main power, the power output shaft of the first driving motor 5 is connected with the bevel gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com