Phosphate dense medium mineral separation and direct-reverse floatation combined technology

A positive and negative flotation, dense medium technology, applied in flotation, solid separation, wet separation, etc., can solve the problems of phosphorus resource loss, silted river course, large quantity, etc., and achieve the effect of improving utilization rate and reducing discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

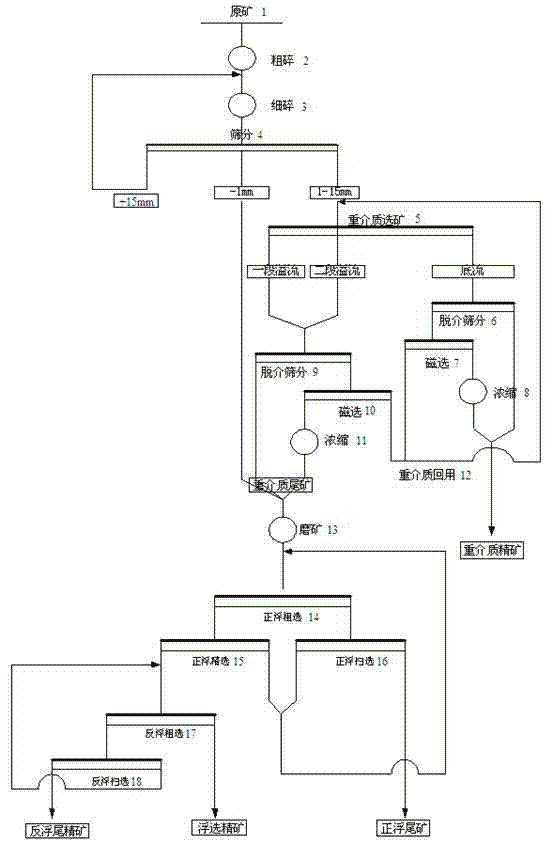

[0029] In this example, the combined process of dense medium beneficiation and positive and negative flotation is carried out on the phosphate rock with a raw ore grade of 19.40%. For the process flow, see figure 1 , the specific process steps are as follows:

[0030] (1) Dense media beneficiation process:

[0031] a. The grade of raw phosphate rock is 19.40%. The raw ore 1 enters the first stage of crushing process (coarse crushing 2) from the hopper for coarse crushing until it reaches -60mm, and the crushed product enters the second stage of crushing process (fine crushing 3). Finely crushing, sieve the finely crushed products to obtain the oversize material larger than 15mm, the coarse particle raw ore of 1~15mm and the undersize raw ore less than 1mm, and the oversize material larger than 15mm is returned to the second stage of crushing process again Carry out fine crushing, and the product under the 1~15mm sieve enters the mineral medium with a density of 2300kg / m 3...

Embodiment 2

[0040] The raw ore grade of this embodiment is 20.2%, and the flow chart of the combined process of phosphate rock heavy media beneficiation and forward and reverse flotation is shown in figure 1 , the specific process is roughly the same as in Example 1, the difference being:

[0041] (1) The grade of the dense medium concentrate obtained through the dense medium beneficiation process is 28.2%, and the recovery rate of the dense medium beneficiation process is 55.14%;

[0042] (2) The concentration of the pulp is 32.5%, and the agent and its dosage for positive flotation roughing are: sodium carbonate 6.0kg / t (weight

[0043] Medium tailings), water glass 3.0kg / t (heavy medium tailings), naphthalene derivatives (FDN) 1.0 kg / t (heavy medium tailings), collector (fatty acid soap) 1.5kg / t (heavy medium Tailings), the temperature of positive flotation roughing is 20°C;

[0044] (3) The agent and dosage of positive flotation sweeping are: collector (fatty acid soap) 0.3kg / t (hea...

Embodiment 3

[0051] The raw ore grade of this embodiment is 21.3%. The flow chart of the combined process of phosphate ore heavy media beneficiation and forward and reverse flotation is shown in figure 1 , the specific process is roughly the same as in Example 1, the difference being:

[0052] (1) The grade of the dense medium concentrate obtained through the dense medium beneficiation process is 28.1%, and the recovery rate of the dense medium beneficiation process is 56.20%;

[0053] (2) The concentration of the pulp is 35%, and the agent and its dosage for positive flotation roughing are: sodium carbonate 7.0kg / t (weight

[0054] Medium tailings), water glass 2.0kg / t (heavy medium tailings), naphthalene derivatives (FDN) 1.2 kg / t (heavy medium tailings), collector (fatty acid soap) 2.0kg / t (heavy medium Tailings), the temperature of positive flotation roughing is 15°C;

[0055] (3) The agent and dosage of positive flotation sweeping are: collector (fatty acid soap) 0.7kg / t (heavy medi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com