Manufacturing method of nuclear-grade austenitic stainless steel welding wire

A technology of austenitic stainless steel and nuclear grade, which is applied in the field of austenitic stainless steel welding consumables for nuclear grade, and can solve the problems of material magnetic properties and neutron radiation resistance control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

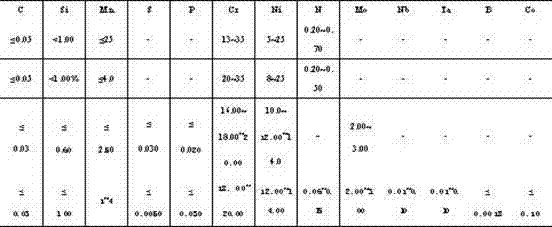

Method used

Image

Examples

Embodiment 1

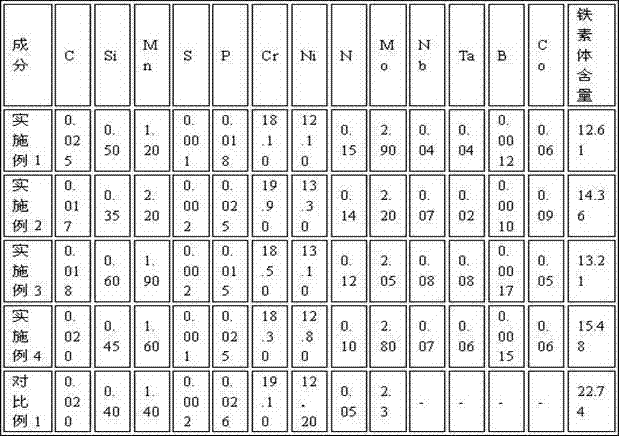

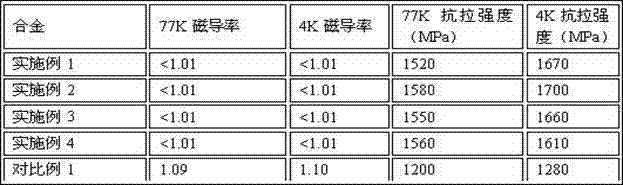

[0045] The composition of austenitic stainless steel according to the present invention is listed in Table 2. It is smelted in an intermediate frequency furnace+vacuum induction furnace, cast into continuous flat ingots, hot-rolled into 5mm after peeling, annealed and pickled at a temperature of 1080°C, and cooled Rolled to 1.5mm and then bright annealed, the sheet has high low-temperature strength, toughness, and non-magnetic properties, and its good resistance to neutron radiation is ensured by controlling the elements of niobium, tantalum, cobalt, and boron. All properties are listed in Table 3.

Embodiment 2

[0047] The composition of austenitic stainless steel according to the present invention is listed in Table 2. It is melted in an intermediate frequency furnace+vacuum induction furnace, cast into a round ingot, forged and hot-rolled into a 5mm wire rod, and after pickling, it is drawn at 1080 ℃ bright annealing into 1mm wire, the plate has high low temperature strength, toughness, non-magnetic properties, and its good anti-neutron radiation performance is guaranteed by controlling the elements of niobium, tantalum, cobalt and boron. All properties are listed in Table 3.

Embodiment 3

[0049] The composition of austenitic stainless steel according to the present invention is listed in Table 2. It is smelted in an intermediate frequency furnace+vacuum induction furnace, cast into continuous flat ingots, hot-rolled into 6mm after peeling, annealed and pickled at a temperature of 1080°C, and cooled Rolled to 2.0mm and then bright annealed, the sheet has high low-temperature strength, toughness, and non-magnetic properties, and its good resistance to neutron radiation is ensured by controlling the elements of niobium, tantalum, cobalt, and boron. All properties are listed in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com